Bereket Alemu, a 29 years old accountant is a customer and neighbour of Fil Wuha Service Enterprise, the largest hot spa in the city used by thousands of residents.

He uses the hot spa, one of the major wastewater dischargers in the city, at least twice a month and sometimes when he feels the urge.

The hot spa is a major contributor of the nearly 460,000m3 of wastewater discharged in Addis Abeba a day, 80pc of the 575,000m3 of water consumed.

Addis Abeba, as the seat of major regional and international organizations, undergoing rapid socio-economic development and supporting a rising population is facing accelerated demand for potable water both from the domestic and industrial front.

At the same time, the city is dealing with a proportional rise in wastewater discharge that requires treatment before beang released into the natural water bodies.

"I don't know where the wastewater goes," Bereket said, "but it most likely ends up in the nearby rivers or on the streets."

Because of a lack of culture in the proper handling of wastewater and the absence of high volume treatment plants, raw sewage and untreated water drain into open trenches and sometimes even flow on the streets.

In an attempt to address the problem, the city administration constructed the Qality Wastewater Treatment Plant, which was inaugurated in July 2018. The plant was built with 250 million dollars financed by the World Bank.

It has a capacity to treat 100,000 square metres of wastewater a day received from nearly one million residents living in six districts: Kolfe Keranyo, Adiss Ketema, Kolfe, Lideta, Arada and Gulele, in addition to some minor areas in the city.

Addis has three natural drainage areas: Akaki Catchment, Eastern Catchment, Qality Catchment. Their are 12 local primary treatment plants around condominium development areas that by themselves treat 27,500 square metres of waste a day in ‘membrane reactors.’

The new Qality plant is entirely devoted to influent that is received from the Qality Catchment. The plant has been operating since 1973 with a capacity of treating 7,500 square metres of influent a day. The old plant has seen no improvement in the intervening years until the current plan was developed.

The new treatment plant took two years to complete and had undergone six months of testing period. The project was contracted out to AKTOR, a Greek construction company, with a Canadian company, Morrison Hershfield Plc, and local firm ARMA Engineering supervising the project.

The plant falls under Category B treatment system classification, one of three classifications developed by the World Bank.

The raw sewage treatment at the Qality Wastewater Treatment has three stages where large objects are screened, suspended sediments and impurities are removed and the resulting liquid is disinfected before its release as effluent.

Category A requires a full environmental assessment; Category B requires a lower level of environmental investigation than the former; and Category C requires no environmental analysis.

The plant falls under Category B, where its potential impact on human population and the environment will be reviewed with a less stringent condition than Category A.

The plant is currently operating with less than 40pc of its capacity, 37,000 square metres of wastewater treatment a day.

There are two main sewer lines feeding the Qality Sewer system, the Western Addis Abeba Sewer Line, which is 28Km long, and the Eastern Addis Abeba Sewer Line, 18Km in length, which is still under construction.

The aim of the treatment plant is to create a stable and healthy environment by reducing wastewater from the environment in the city and to protect public health, according to Zekarias Fanta, sewage collection treatment and re-use core process leader.

According to the World Health Organization (WHO), wastewater treatment includes removing suspended particles, organic material, bacteria, parasitic organisms, allege, viruses and fungi from the influent. The process also involves the removal of medical and pharmacological substances and industrial chemicals.

The Qality Plant, however, does not have the capacity to remove industrial and pharmacological waste and is limited to treating domestic influent from bathroom and kitchen waste, according to Tadeg Mengesha, a process engineer at the plant.

The two main sewer lines convey wastewater to Qality Plant from multiple lateral lines that are connected to households in a network spread across the city.

The collected waste then enters the primary treatment area, where large floating objects such as plastic bottles, sticks and rags are screened out using 75mm and 50mm square screens and the odor is treated.

The secondary treatment is where microorganisms and suspended solid matter are removed from the wastewater in big tanks where nearly 20 cylinders with a capacity to treat 2,000 square metres each help ensure further break down and treatment of the influent.

The final tertiary treatment removes 70pc of impurities from the wastewater. Then the wastewater is disinfected in a mixture of chlorine and sodium hypochlorite before being released as effluent. The solid matter produced in the process then undergo incineration in heat digesters.

The treated effluent from the new plant is directly released into neighbouring vegetable crop farmlands that lie adjacent to the plant and the Aqaqi River. There are no other facilities to recycle or re-use the effluent beyond the treatment. Some crop farmers have benefited from the release of treated water in the past but are now facing new challenges.

Two local brothers, Abiy Amenu and Aregahegn Amenu, are farmers who live in Aqaqi Qality sub-city near the plant.

Although the city is facing a rising demand in water use and confronting constant shortages, treated wastewater is not being properly utilised, even by adjacent farmers as is happening in Qality.

The brothers inherited the farm from their father, and they have been using the effluent water for cultivation ever since the establishment of the old plant.

The main difference between the old and the new plant, they argue, is that they receive more effluent now and the new water has less of a bad odor. However, they point out that the effluent they received from the old plant was cleaner on the whole, and matters have gotten worse in recent months.

The brothers claim that no effluent is currently being released from the new plant, as it is being used to irrigate hay within the plant compound.

The farmers claim that whatever effluent being released now from the plant is no longer clean or suitable for farming, although they were told otherwise.

The Amenu brothers point to a pond with raw untreated sewage flowing on the surface that has been discharged from the plant. The plant operators do not dispute that raw sewage is being released, and they claim that it is caused by operation deficiencies dealing with sewage trucked to the plant.

“We used to grow vegetables, but now we have turned our fields to growing hay,” said Abiy.

Hay, grown seasonally, generates good income but not as much as crop vegetables.

“Releasing untreated sewage is illegal and cannot be a solution for the problem,” Jemal argues.

Without disputing the claims made by the farmers on the release of raw sewage on farmland, Tadeg said that the problem does exist and that the management is working to remedy the problem and facilitate all the proper services.

One of the other challenges facing the plant is its inability to regulate the acidity of the treated wastewater. The new plant does not have the capability to regulate pH, the scale that measures acidity, and the release of acidic effluent into the environment is a major health concern.

“We have informed people not to use the effluent to cultivate food crops,” said Misbah Idreas, administrator of the plant.

There is also the claim of illegal hookups to the main sewer lines by industrial sources that may account for the high level of acidity problem in the treated wastewater. Acknowledging this problem, Zekarias argues that the main reason behind this is an infrastructure problem, especially when there is construction damage done to sewer lines.

The plant is not currently running at full capacity, as there are a number of other challenges facing the plant including water and electric power supply interruptions. The lack of awareness about wastewater issues among the residents has also been cited by Zekarias as a problem.

"It's very difficult to install sewer pipes in the city even when the people are cooperating, primarily due to existing infrastructure deficiencies," Zekarias said.

Many treatment plants around the world use treated water as a recycled product for irrigation, construction, car washes and other uses outside of human consumption.

As Zekarias says, the main purpose of the plant is to protect the health of citizens and the environment, as well as to recycle the treated effluent and put it to good use.

Zekarias acknowledges that there is very little if any experience in industrial scale wastewater treatment in the country. There is still more work that needs to be done to achieve full capacity.

He states that the country needs more help from experienced countries and firms to participate in solving the problem.

“We have called an international bid for companies to support in the operation of the plant, as well as maintenance, and also to provide training for our workers,” said Zekarias.

Reusing the wastewater depends on the quality of the treated water, according to Jemal Mohammed, a civil engineer and consultant on water supplies and sanitation issues.

Although the city is facing a rising demand in water use and confronting constant shortages, treated wastewater is not being properly utilised, even by adjacent farmers as is happening in Qality.

"Resources are limited, but demands for water are increasing with a rising population," said Tadeg. "We're conducting a study to start recycling and reusing the treated wastewater for different applications."

Since the treatment plant has limited the capacity to treat household wastewater, industries have to implement their own treatment plans before they release their wastewater into the environment, according to Tadeg.

"The authorities have to conduct monitoring and follow-ups, especially in industrial areas,” suggests Jemal, adding that institutional strength is needed and that building a treatment plant cannot be the only solution unless there is an effort to regulate and contain the wastewater problem.

PUBLISHED ON

Apr 26,2019 [ VOL

20 , NO

991]

Viewpoints | Mar 25,2023

Viewpoints | May 29,2021

Fortune News | Aug 12,2023

View From Arada | Oct 26,2024

Fortune News | Jun 27,2020

Fortune News | Sep 24,2018

Radar | May 04,2019

Agenda | Dec 21,2019

Radar | Aug 03,2019

Dec 22 , 2024 . By TIZITA SHEWAFERAW

Charged with transforming colossal state-owned enterprises into modern and competitiv...

Aug 18 , 2024 . By AKSAH ITALO

Although predictable Yonas Zerihun's job in the ride-hailing service is not immune to...

Jul 28 , 2024 . By TIZITA SHEWAFERAW

Unhabitual, perhaps too many, Samuel Gebreyohannes, 38, used to occasionally enjoy a couple of beers at breakfast. However, he recently swit...

Jul 13 , 2024 . By AKSAH ITALO

Investors who rely on tractors, trucks, and field vehicles for commuting, transporting commodities, and f...

Jun 28 , 2025

Meseret Damtie, the assertive auditor general, has never been shy about naming names...

Jun 21 , 2025

A well-worn adage says, “Budget is not destiny, but it is direction.” Examining t...

Jun 14 , 2025

Yet again, the Horn of Africa is bracing for trouble. A region already frayed by wars...

Jun 7 , 2025

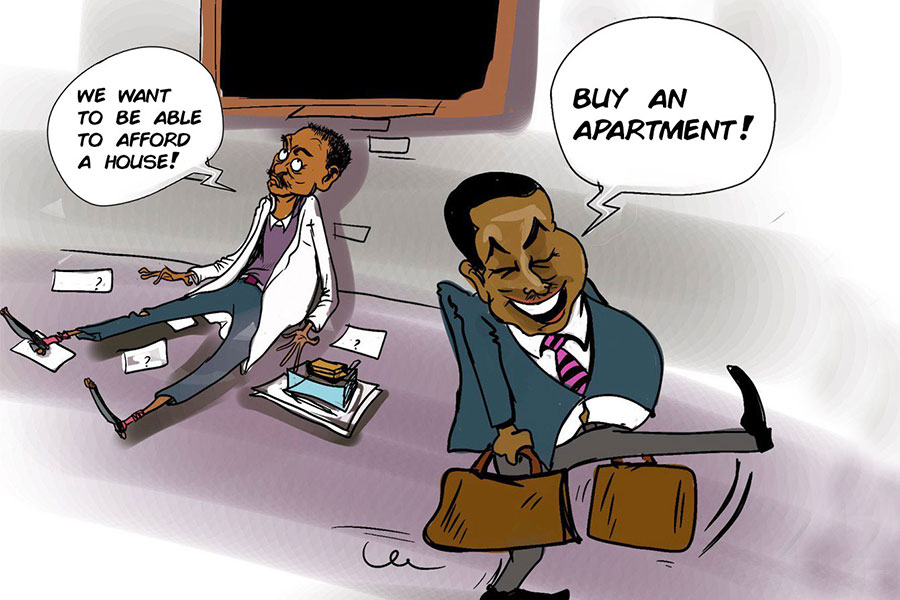

Few promises shine brighter in Addis Abeba than the pledge of a roof for every family...