Bishoftu Automotive Engineering Industry, a subsidiary of Metals & Engineering Corporation (MetEC), secured a deal to supply 350 pickup trucks worth over half a billion Birr to public offices.

The Ethiopian Construction Works Enterprise, the Defense Construction Enterprise, different town administrations, and federal and regional courts have made a deal with Bishoftu Automotive Engineering Industry for the assembly and supply of the vehicles at a cost of about 560 million Br. The contract includes 310 N2s model double-cabin and 40 N3 double-cabin pickup trucks.

Originally, Liaoning signed an agreement three years ago with Bishoftu Automotive to provide parts for 500 pickups.

Thus far, Bishoftu Automotive has imported 150 pickups from the total for different government organisations.

Bishoftu Automotive, which was re-established in 2010 with a capacity to assemble four vehicles every eight hours, has already imported the components for 60 N2s model double-cabin pickups two months ago. And so far it has assembled and delivered seven of those vehicles.

The components for the rest of the 290 light vehicles are expected to be imported within the coming two months, according to Fikiru Abebe, head of a secretariat office at Bishoftu Automotive, which was first established in 1984 and operated under the Ministry of Defence. It was re-established in 2010 as a public enterprise under MetEC to perform a leading role in assembling military and commercial vehicles.

Bishoftu Automotive, which resides on the premises of MetEC's headquarters in Bishoftu (Debre Zeit), 40Km south of the capital, was awarded the contract through a direct procurement process, according to Fikiru.

The company hopes to deliver all of the vehicles within five months, according to Fikiru.

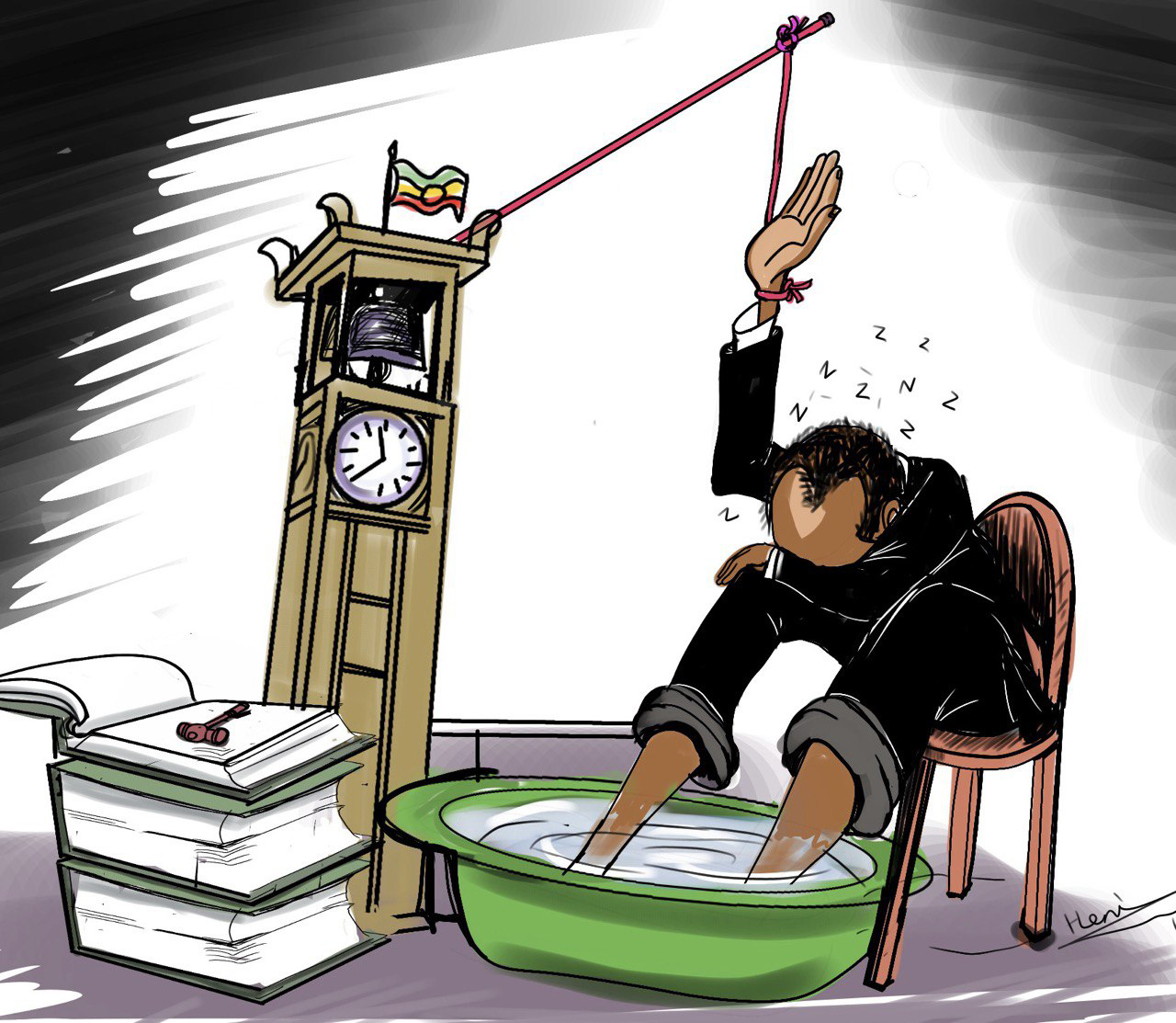

It can not produce the vehicles quickly, however, due to the pandemic, the ongoing foreign currency crunch and a labour force shortage, according to Fikiru.

The engineering industrial firm, which has over 3,000 employees, is now operating with 200 to 300 employees due to the Novel Coronavirus (COVID-19) pandemic, which has resulted in the restrictions against public gatherings.

The Ethiopian Construction Works Corporation, which was re-established in December 2015 and operates in six sectors, signed an agreement with Bishoftu last week to procure 25 light vehicles.

“The order we gave them was for 35 light vehicles, but since they had other orders, they offered us 10 less,” said Alehegn Mossu, deputy CEO of the Corporation in charge of construction equipment and the machinery management division.

After the Corporation receives the pickups they will be deployed to more than 30 new and existing projects, according to Alehegn.

The Corporation has been sourcing the components for pick-up truck from Liaoning since its establishment. However, it is planning to work with different companies, according to Fikiru.

“We're preparing to announce an international tender to work with raw material suppliers,” said Fikiru.

So far, Bishoftu Automotive has supplied a total of 126 heavy trucks of four different models to the Corporation for 327 million Br. Additionally, it assembles and provides military armaments to local and international clients, including the Africa Union (AU).

Bishoftu Automotive has also upgraded to European emission standards, a requirement that governs air pollutants released into the atmosphere from engines. It also improved the vehicle's engine net weight by 30Kg, from 220Kg, and pushed the engine's maximum horsepower to 109.

In the eyes of Eshetie Berhan (PhD), an associate professor at Addis Abeba University’s Institution of Technology in the department of mechanical & industrial engineering, assembling vehicles locally is advantageous for saving foreign currency and building local capacity.

He also said that the pandemic might not impact the company from importing the components since most countries are opening up.

"Unless there is a shortage of foreign currency, international shipping will not be a challenge for them, because they started activities," Eshetie said.

Eshetie also wonders how long the company will keep on importing components.

“The share of the locally-produced material on the assembled vehicles should be increased,” said Eshetie. "The company should partner with the small and medium manufacturers to substitute the components locally."

PUBLISHED ON

Jun 14,2020 [ VOL

21 , NO

1051]

Fortune News | Nov 21,2018

Fortune News | Jun 12,2021

Editorial | Dec 02,2023

Fortune News | Oct 28,2023

Fortune News | Dec 28,2019

Featured | Jan 05,2019

Viewpoints | Jul 10,2021

Commentaries | Nov 14,2020

Editorial | Jun 22,2019

Life Matters | Nov 27,2021

Dec 22 , 2024 . By TIZITA SHEWAFERAW

Charged with transforming colossal state-owned enterprises into modern and competitiv...

Aug 18 , 2024 . By AKSAH ITALO

Although predictable Yonas Zerihun's job in the ride-hailing service is not immune to...

Jul 28 , 2024 . By TIZITA SHEWAFERAW

Unhabitual, perhaps too many, Samuel Gebreyohannes, 38, used to occasionally enjoy a couple of beers at breakfast. However, he recently swit...

Jul 13 , 2024 . By AKSAH ITALO

Investors who rely on tractors, trucks, and field vehicles for commuting, transporting commodities, and f...

Jul 12 , 2025

Political leaders and their policy advisors often promise great leaps forward, yet th...

Jul 5 , 2025

Six years ago, Ethiopia was the darling of international liberal commentators. A year...

Jun 28 , 2025

Meseret Damtie, the assertive auditor general, has never been shy about naming names...

Jun 21 , 2025

A well-worn adage says, “Budget is not destiny, but it is direction.” Examining t...