Several cement plants will undergo maintenance beginning next month, aggravating fears that shortages in supply will send retail prices through the roof.

The new schedule has been set despite the recurring cement shortage facing the construction industry. Construction activities across the country have been abbreviated since last year due to a combination of factors, including a surge in the prices of building materials.

Officials at the Ethiopian Chemical & Construction Inputs Industry Development Institute, which is under the auspices of the Ministry of Trade & Industry, have requested the association of cement producers to collect the maintenance schedules of each cement plant and submit them for their approval.

There are 13 cement plants with an aggregate production capacity of 8.4 million tonnes annually. Derba Cement, owned by Mohammed Ali Al-Amoudi and his family, has the largest capacity of 2.5 million tonnes, followed by Messebo Cement, which produces 200,000tn less. The latter had been closed for four months due to the military conflict in the Tigray Regional State, where it is located, before it began partial production in late March this year. Annual demand for cement is estimated to have reached 11.5 million tonnes.

There has not been full maintenance of cement plants for the last three years, those in the industry say.

According to Habtamu Arage, deputy director-general of the Institute, this has impacted the productivity of the plants and is partly responsible for the shortage of cement.

The maintenance of each cement plant is expected to take no less than 45 days. But considering the existing shortage of cement, the Institute has directed the plants to shorten the time they stay closed by two weeks.

Cement plants were allowed to undergo maintenance upon their respective schedules, although authorities, made anxious by the inhibited construction industry due to the shortage of the item, introduced a new rule demanding managers of the plants to present their schedule before doing so. The majority of cement producers prefer the rainy season as an ideal period to carry out maintenance works on their plants.

The National Bank of Ethiopia (NBE) has already availed 85 million dollars to all cement factories, which have used their allocated share of forex to buy spare parts for the maintenance works.

A subsidiary of the East African Holdings, the National Cement in Dire Dawa, has finalised preparations to start maintenance works soon. Having a capacity to produce 4,200tn of cement daily, National Cement has already brought in spare parts to start the maintenance in the rainy season.

"There is a slowdown in construction activities during the rainy season," said Fitsum N. Demissie, CEO of East African Trading House and board member of the Ethiopian Cement Manufacturers Association. "The impact of the maintenance of all cement plants would not be significant."

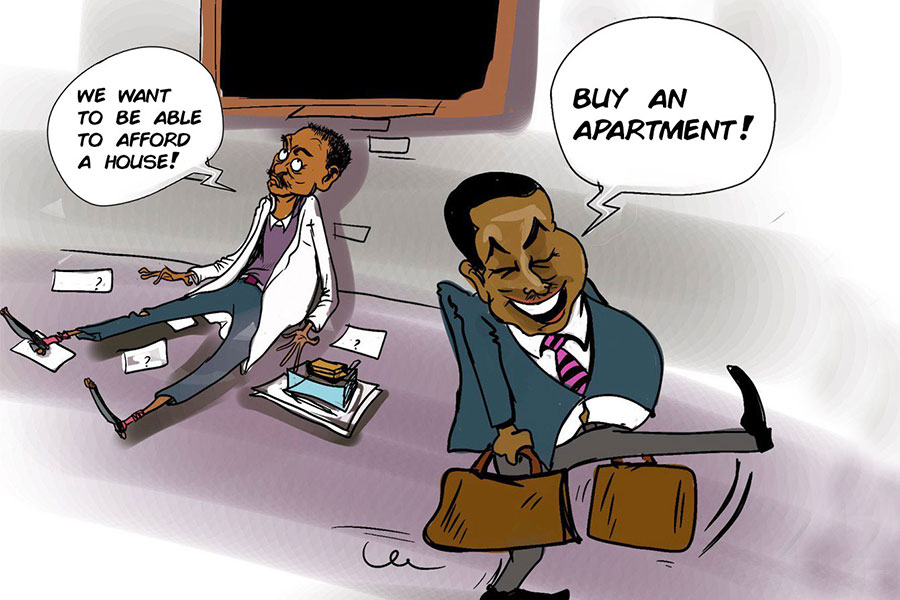

The market feels differently. Retailers complain that they have not been able to get cement for months, opening the doors for an underground cement trade to thrive in the city, with a quintal selling for as much as 750 Br, almost double the rate capped by the Ministry of Trade. They fear the shortfall in supply would be severely exacerbated if the maintenance begins before the current demand is addressed.

Hagos Tesfaye is a cement retailer whose store in the Megenagna area, a place where a large number of retailers are concentrated, was empty last week.

"I have not been able to get a quintal of cement for the last two months," he told Fortune.

The supply shortage is already impacting ongoing projects, including the construction of Ethiopia's biggest national stadium (Adey Abeba), under construction in Bole District at the cost of 5.5 billion Br. The project receives cement twice a week, despite its 20tn demand a day, causing delays on the project completion time, according to Asmara Gizaw, director of sports facilities at the Federal Sports Commission.

"If the shortage persists, we'll be forced to stop the construction," he told Fortune.

The authorities and managers of cement plants are in a "Catch 22" dilemma. If they let the plants continue to operate, ignoring maintenance works seen as indispensable, the average production capacity will drop from the current 60pc down to 50pc, industry experts warn. Shutting down plants for maintenance would fuel speculation and drive prices up.

"Considering their existing condition, if they're not going to be maintained this year, their capacity will fall," said the Deputy Director-General of the Institute. "This will further complicate the situation and worsen the shortage."

PUBLISHED ON

Jun 12,2021 [ VOL

22 , NO

1102]

Fortune News | Jan 07,2022

Exclusive Interviews | Nov 21,2018

Commentaries | Aug 25,2024

Fortune News | Mar 20,2021

Fortune News | Jun 14,2020

Sunday with Eden | May 20,2023

Fortune News | Apr 30,2022

Fortune News | Nov 30,2019

Radar | May 24,2025

Dec 22 , 2024 . By TIZITA SHEWAFERAW

Charged with transforming colossal state-owned enterprises into modern and competitiv...

Aug 18 , 2024 . By AKSAH ITALO

Although predictable Yonas Zerihun's job in the ride-hailing service is not immune to...

Jul 28 , 2024 . By TIZITA SHEWAFERAW

Unhabitual, perhaps too many, Samuel Gebreyohannes, 38, used to occasionally enjoy a couple of beers at breakfast. However, he recently swit...

Jul 13 , 2024 . By AKSAH ITALO

Investors who rely on tractors, trucks, and field vehicles for commuting, transporting commodities, and f...

Jun 28 , 2025

Meseret Damtie, the assertive auditor general, has never been shy about naming names...

Jun 21 , 2025

A well-worn adage says, “Budget is not destiny, but it is direction.” Examining t...

Jun 14 , 2025

Yet again, the Horn of Africa is bracing for trouble. A region already frayed by wars...

Jun 7 , 2025

Few promises shine brighter in Addis Abeba than the pledge of a roof for every family...