Apr 13 , 2019

By TEMESGEN MULUGETA ( FORTUNE STAFF WRITER )

A 47-million-Br flour factory has set up shop in East Gojjam, Yejube town, in Amhara Regional State, entirely financed by local business A.S.S.E.S. Industry Plc.

Sitting on a 1,254Sqm plot, the new company entered the market this week with a processing capacity of 820ql of flour a day. The construction of the plant took 18 months and was completed by Abiyot Tadesse Engineering. The machinery was imported last August from Hebei Pingle Flour Machinery Group, a two-decade-old Chinese firm that provides flour mill machines with milling capacities of between nine tonnes to 1,000tn of flour an hour, for 8.9 million Br.

Since last February, the company has been testing operations on a trial basis producing 2,000ql of flour with 50 employees.

The owners were interested in investing in the area as it is known for wheat production, according to Sema Melaku, deputy manager of the factory.

Amhara Regional State is second in wheat production in the country. Around 4.6 million tonnes of wheat grain was harvested in Ethiopia during the last fiscal year, with the Amhara region accounting for 32.7pc and Oromia contributing the largest share at 53pc. The country imported 1.7 million tonnes of wheat in the last fiscal year at a cost of five billion Birr.

"We are planning to expand our investment to animal feed and macaroni production in the coming year," Sema told Fortune.

The company is only the fifth company to secure a certificate from the Ethiopian Conformity Assessment Enterprise. Companies that engage in coffee processing, candy processing and water bottling are required to secure the certificate, according to Take Berhane, marketing and corporate communications director of the Enterprise.

The new plant will be joining 110 other registered flour milling companies in the country, of which 86 are located in the capital. These factories supply flour for 4,461 certified biscuit, cake and bread makers around the nation.

Molla Wassie, a lecturer in Bahir Dar University's economics department, believes that the company has to work with farmers in the area.

"It will make the factory get quality wheat grain and at the same time help the farmers by creating a stable market," Molla said.

The agricultural sector contributes 34pc of the country’s gross domestic product and employs over two-thirds of the workforce, where 72pc are engaged in crop production.

The company has already started to face challenges even before going operational, according to the deputy general manager.

"During our trial production, we faced a shortage of electric power and water supply" said Sema. "We can't even wash wheat before processing due to a shortage of water, and the electricity interruptions prevented us from drying our washed wheat."

PUBLISHED ON

Apr 13,2019 [ VOL

20 , NO

989]

Fortune News | Feb 26,2022

Radar | Nov 23,2019

Fortune News | Apr 30,2021

Fortune News | Sep 28,2024

Radar | Mar 18,2023

Featured | Sep 27,2020

Featured | Apr 26,2019

Commentaries | Jan 07,2024

Sunday with Eden | Dec 10,2022

Dec 22 , 2024 . By TIZITA SHEWAFERAW

Charged with transforming colossal state-owned enterprises into modern and competitiv...

Aug 18 , 2024 . By AKSAH ITALO

Although predictable Yonas Zerihun's job in the ride-hailing service is not immune to...

Jul 28 , 2024 . By TIZITA SHEWAFERAW

Unhabitual, perhaps too many, Samuel Gebreyohannes, 38, used to occasionally enjoy a couple of beers at breakfast. However, he recently swit...

Jul 13 , 2024 . By AKSAH ITALO

Investors who rely on tractors, trucks, and field vehicles for commuting, transporting commodities, and f...

Jun 28 , 2025

Meseret Damtie, the assertive auditor general, has never been shy about naming names...

Jun 21 , 2025

A well-worn adage says, “Budget is not destiny, but it is direction.” Examining t...

Jun 14 , 2025

Yet again, the Horn of Africa is bracing for trouble. A region already frayed by wars...

Jun 7 , 2025

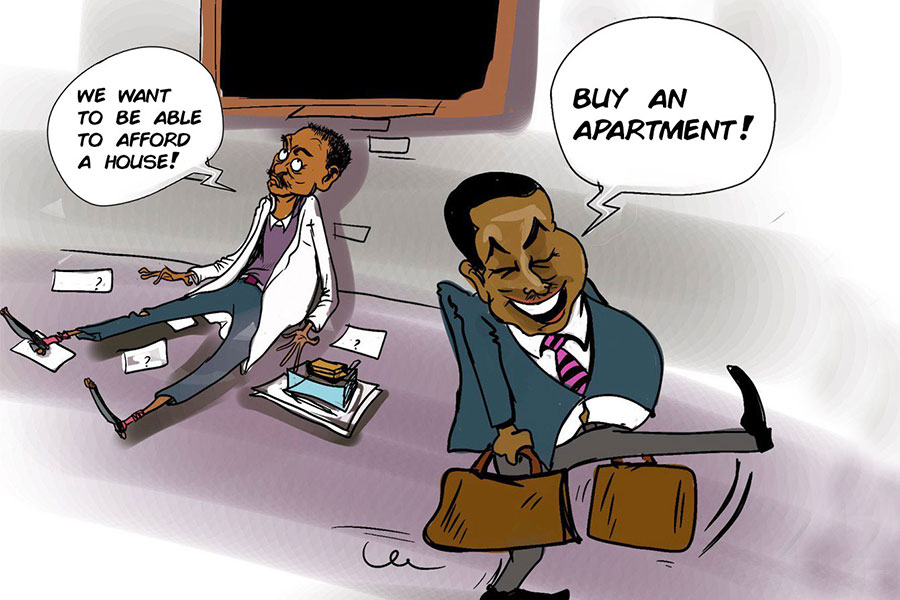

Few promises shine brighter in Addis Abeba than the pledge of a roof for every family...