My Opinion | Feb 12,2022

A domestically-owned edible oil processing plant worth five billion Br, equivalent to the minimum paid-up capital required to establish a bank, has kicked off its operations. WA Oil Factory, built under the watch of its major shareholder and Chief Executive Officer, Worku Aytenew, the renowned businessperson involved in different sectors, has been under construction for almost five years.

The construction was handled by Chinese contractors, while expatriates were hired during the installation of machinery, commissioning, and testing periods. It will be inaugurated by the end of next week in the presence of government officials and other guests.

Having the capacity to process 1.3 million litres of edible oil daily, the plant is located in East Gojjam Zone, Amhara Regional State. It is the ninth investment of the WA group, which has been involved in the mining, aviation, farming, real estate, petroleum, and water bottling sectors as well as the trading and distribution of imported oil.

Having its head office in Addis Abeba, the new plant can also crush and produce edible oil from niger seed, sesame seed, peanut, soya bean, and haricot bean, besides being able to process crude palm oil imported from abroad.

Even though the factory's civil works were completed earlier this year, its management had been waiting until the state-owned Ethiopian Electric Power builds a transformer and connects it with the national grid. Four megawatts of electricity is needed to run the factory.

"We're getting enough amounts of electricity to run the factory," said Alazar Ahmed, chief marketing officer of WA. "Testing has been completed successfully." With a target of creating a linkage with at least 2,500 farmers to source raw materials, the factory has already stocked inputs needed to fully start production, according to him. "We have applied the latest German technology to run our machines," the marketing chief added.

WA is the third edible oil factory to be inaugurated this year. With an investment capital of 4.5 billion Birr, Phibela Industrial, having the potential of processing 1.6 million litres a day, was inaugurated in February 2021. A month later, another factory in Dire Dawa, Shemu Plc, officially began its operations with a daily production capacity of 220,000 litres of edible oil, investing 1.6 billion Br thus far. While both started production with a refinery, WA wants to buck the trend.

"Aiming to save foreign currency, we'd like to source our raw materials from farmers," Alazar said. But he did not hide the difficulty of accessing inputs locally because of the low production of agricultural commodities in the country.

During the last fiscal year, 7.7 million quintals of oilseeds, including sunflower and sesame, were produced across Ethiopia, portraying an eight percent annual decline. With a large chunk of such commodities exported abroad, most edible oil plants prefer to import the crude edible oil and refine it here, a path which has been followed by Phibela because of the unreliability of supplying inputs locally.

"In three years, we want to produce input on our own farm to make sure the supply chain is reliable. Until then, we'll keep refining the crude edible oil," remarked Eniyew Wassie, chief executive officer of Phibela.

Understanding such challenges and as a strategy to substitute direct imports of edible oil, the government has given a priority to refineries in availing foreign currency needed to import the crude edible oil, largely from Malaysia and Indonesia. The per capita monthly consumption of edible oil stands at 0.7 litres in Ethiopia, where the total demand stands at 71 million litres a month, half of which is being produced locally.

With the joining of four oil manufacturing projects, the country would be able to produce 50.6 million litres of palm, 27 million litres of sunflower, and 21.8 million litres of soybean oil annually.

But for Getachew Asfaw, an expert in economic planning with vast experience, this is only possible if there will be enough amount of forex required to import crude edible oil.

"This is a country where every dollar matters. The ultimate solution is boosting local production and substituting the raw materials, which can be harvested easily in the country," said Getachew, suggesting that commercial farmers must be given an incentive to produce such commodities to satisfy the demand of the edible oil plants.

PUBLISHED ON

May 29,2021 [ VOL

22 , NO

1100]

My Opinion | Feb 12,2022

Editorial | Jul 09,2022

Fortune News | Apr 30,2021

Radar | Mar 12,2022

Fortune News | Jul 25,2020

Fortune News | Apr 13,2019

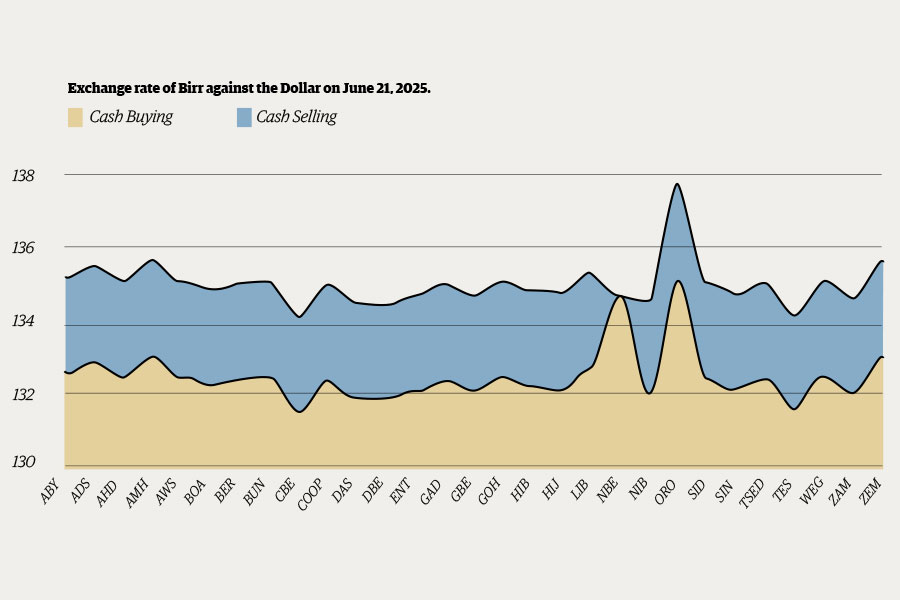

Money Market Watch | Jun 21,2025

Fortune News | Feb 26,2022

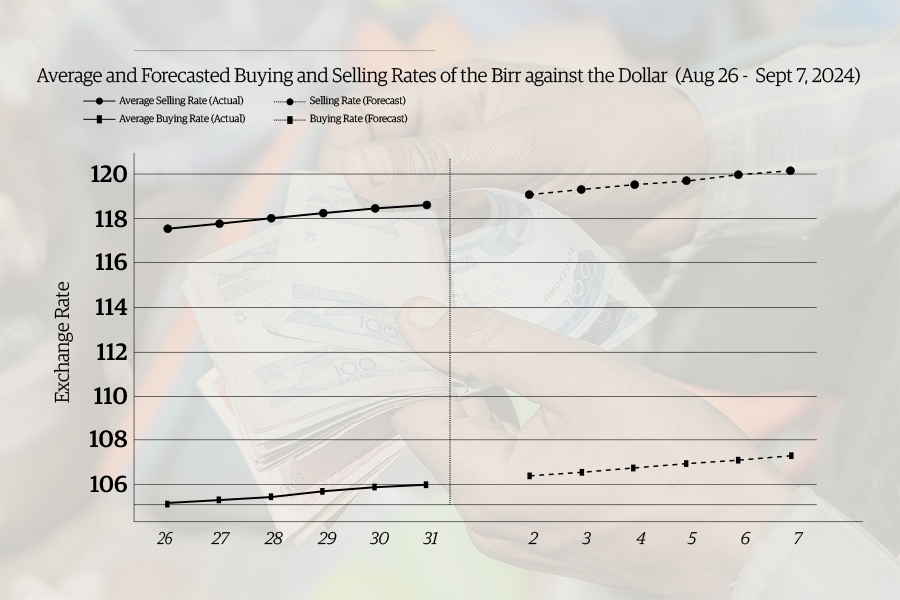

Money Market Watch | Sep 01,2024

Fortune News | Aug 10,2019

Dec 22 , 2024 . By TIZITA SHEWAFERAW

Charged with transforming colossal state-owned enterprises into modern and competitiv...

Aug 18 , 2024 . By AKSAH ITALO

Although predictable Yonas Zerihun's job in the ride-hailing service is not immune to...

Jul 28 , 2024 . By TIZITA SHEWAFERAW

Unhabitual, perhaps too many, Samuel Gebreyohannes, 38, used to occasionally enjoy a couple of beers at breakfast. However, he recently swit...

Jul 13 , 2024 . By AKSAH ITALO

Investors who rely on tractors, trucks, and field vehicles for commuting, transporting commodities, and f...

Jul 5 , 2025

Six years ago, Ethiopia was the darling of international liberal commentators. A year...

Jun 28 , 2025

Meseret Damtie, the assertive auditor general, has never been shy about naming names...

Jun 21 , 2025

A well-worn adage says, “Budget is not destiny, but it is direction.” Examining t...

Jun 14 , 2025

Yet again, the Horn of Africa is bracing for trouble. A region already frayed by wars...