Jul 13 , 2024

By Yemanebrhan Kiros

The industrial sector is turning up the heat – but not how it should be. As the government pushes for a carbon-neutral economy by 2030, traditional fossil-fuel boilers may soon be relics of the past. Enter heat pumps, the unsung heroes that generate three to four times more heat per kilowatt of energy. With this game-changing tech, industries like breweries and textile mills can slash energy bills and CO2 emissions. But are they ready to make the switch, wonders Yemanebrhan Kiros (yomemech@gmail.com), manager at Yomener Energy Auditing & Engineering Plc.

Committed to international climate change initiatives, Ethiopia faces problems in reducing energy consumption and emissions. Its leaders' ambitious goals, articulated through the Clean & Resilient Green Economy (CRGE) initiative and nationally determined contributions (NDCs) to the Paris Agreement, demand a concerted effort across various sectors, especially industry. The CRGE and NDCs are designed to build a carbon-neutral and clean economy by 2030, requiring substantial reductions in greenhouse gas emissions, improvements in energy efficiency, and a transition to renewable energy sources.

A major energy consumer, the industrial sector is crucial to this transition.

Heating is essential in many industrial processes, such as drying, dyeing, washing, and chemical processing. Typically, heat is generated by fossil-fuel-fired boilers or electrically heated systems. Electric systems consume about one kilowatt of energy for every kilowatt of heat produced. In contrast, fossil-fuel systems convert approximately 85pc of the energy in the fuel to proper heat. However, heat pumps, which consume only one kilowatt of electric energy to produce three to four kilowatts of heat, offer a more efficient alternative.

Ethiopia must focus on energy efficiency and adopting energy-efficient technologies like heat pumps to meet international and national emission reduction targets. While renewable energy sources are essential, the greatest carbon reduction can be achieved through the combination of energy efficiency measures and the use of renewables. Improved access to and distribution of renewable energy can further enhance these efforts.

Unfortunately, many industrial players in Ethiopia are not yet aware of the benefits of heat pump technology. There is an urgent need for awareness creation and advocacy to promote the adoption of this technology. Government organisations and development partners must play a crucial role in this effort, as more action is needed to reduce emissions while supporting industrial growth.

The pace of Ethiopia's efforts to reduce emissions has been sluggish, and the country must accelerate its activities to meet its 2030 goals. Stakeholders and development partners must collaborate to ensure the necessary actions are taken to protect the environment and sustain industrial progress. Integrating heat pump technology in industrial processes is vital to achieving these objectives.

Heat pumps are particularly advantageous as they do not generate heat directly but instead move and concentrate ambient heat using a small amount of electricity. This process makes them 300pc to 400pc more efficient than traditional systems. Some manufacturers claim their products can deliver up to five times the heating energy per kilowatt of power consumed using advanced refrigerants like helium and CO2. However, these systems require higher pressures, up to 30 bar.

Heat pumps take advantage of refrigerants' phase change, which causes them to boil at lower temperatures, allowing them to extract heat from the environment even at low temperatures. The refrigerant is then compressed to increase its temperature, allowing the harvested heat to be used for industrial processes. The system requires energy only to drive the compressor, fan, or pump, making it highly efficient.

Where energy efficiency is an economic imperative, like in Ethiopia, installing heat pumps represents a sound investment. Industries such as breweries, paper mills, textiles, tanneries, milk processing, and beverages requiring large amounts of hot water daily could benefit from heat pump technology. Currently, these industries rely on electric or fossil-fuel-fired boilers with much lower efficiency. Their facilities could substantially reduce their energy bills and CO2 emissions by installing heat pumps, enhancing their competitiveness and contributing to national emission reduction goals.

Over the past 10 to 15 years, the hospitality sector has increasingly adopted heat pump technology for domestic hot water generation. Engineers in the building sector deserve commendation for this shift, which has led to major operational cost savings for developers, despite higher initial investments. Some have even integrated heat pumps with solar systems, optimising economic benefits. In these setups, the solar system can take over when sufficient hot water is available, further reducing the compressor's required power input.

Cost savings from improved energy efficiency are critical for industries where energy expenses constitute 30pc to 40pc of production costs. Reducing energy consumption through heat pump technology cuts operational costs and helps businesses cope with rising energy prices. As emissions regulations tighten, industries must find ways to reduce their environmental impact. Heat pumps, which can also capture and harness waste heat from industrial processes, offer a viable solution for increasing overall industrial efficiency.

However, heat pumps have their limitations.

They can produce hot water up to only 80 degrees Celsius, which may not be sufficient for all industrial needs. For higher temperature demands, industries can use heat pumps to preheat water to the maximum possible temperature and then rely on conventional systems for further heating. This approach still results in considerable energy savings, as it reduces the amount of energy required by the conventional system.

Heat pumps are relatively maintenance-free once properly installed, offering long-term cost savings. The energy savings achieved through heat pumps can impact the country's overall energy consumption and emission reductions, contributing to foreign currency savings and achieving CRGE targets.

PUBLISHED ON

Jul 13,2024 [ VOL

25 , NO

1263]

View From Arada | Aug 31,2019

Commentaries | Dec 10,2018

Radar | Apr 06,2019

Commentaries | Aug 05,2023

Commentaries | Jan 28,2023

Fortune News | Dec 28,2019

Fortune News | Aug 24,2019

Editorial | May 25,2019

Radar | Apr 09,2022

Verbatim | Nov 21,2020

My Opinion | 131659 Views | Aug 14,2021

My Opinion | 128023 Views | Aug 21,2021

My Opinion | 125986 Views | Sep 10,2021

My Opinion | 123610 Views | Aug 07,2021

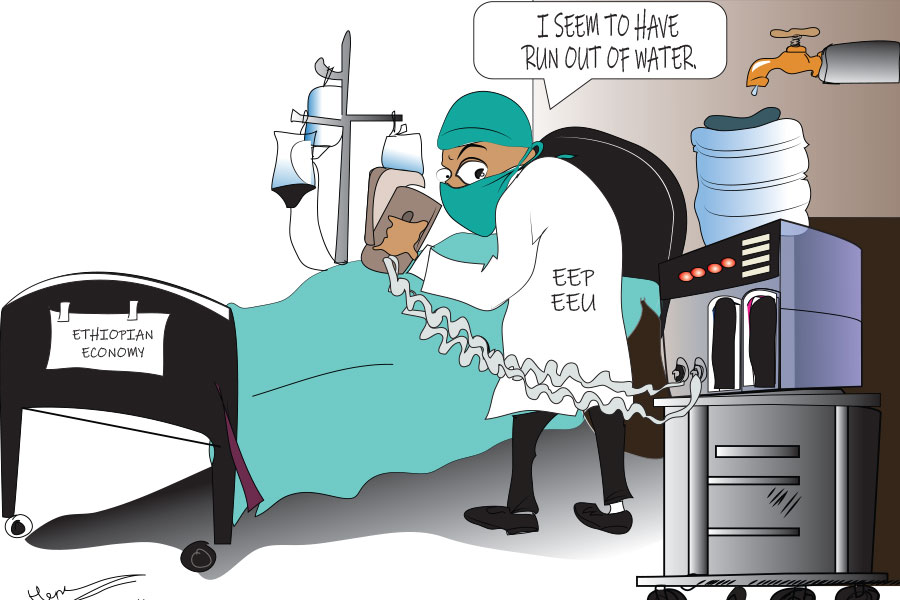

Dec 22 , 2024 . By TIZITA SHEWAFERAW

Charged with transforming colossal state-owned enterprises into modern and competitiv...

Aug 18 , 2024 . By AKSAH ITALO

Although predictable Yonas Zerihun's job in the ride-hailing service is not immune to...

Jul 28 , 2024 . By TIZITA SHEWAFERAW

Unhabitual, perhaps too many, Samuel Gebreyohannes, 38, used to occasionally enjoy a couple of beers at breakfast. However, he recently swit...

Jul 13 , 2024 . By AKSAH ITALO

Investors who rely on tractors, trucks, and field vehicles for commuting, transporting commodities, and f...

Jun 28 , 2025

Meseret Damtie, the assertive auditor general, has never been shy about naming names...

Jun 21 , 2025

A well-worn adage says, “Budget is not destiny, but it is direction.” Examining t...

Jun 14 , 2025

Yet again, the Horn of Africa is bracing for trouble. A region already frayed by wars...

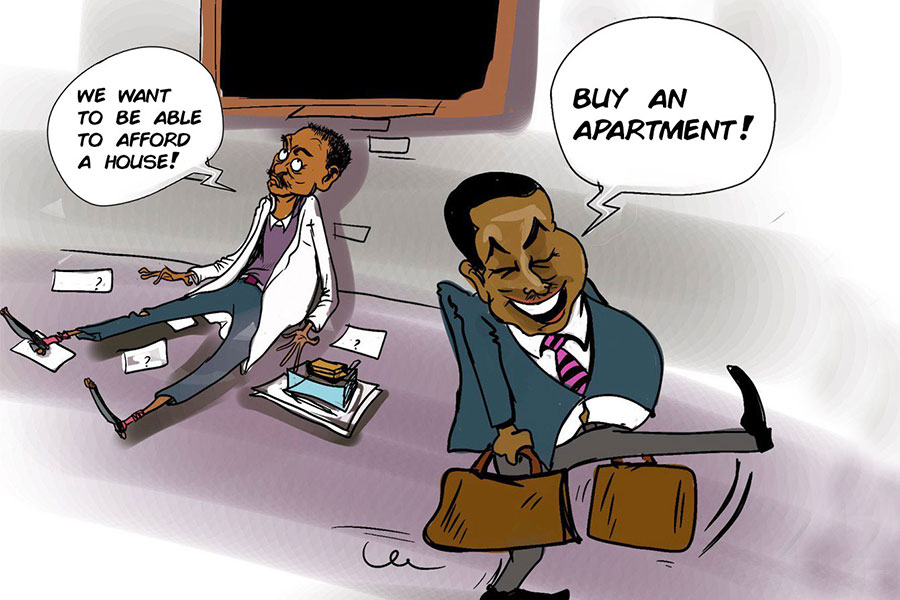

Jun 7 , 2025

Few promises shine brighter in Addis Abeba than the pledge of a roof for every family...

Jun 29 , 2025

Addis Abeba's first rains have coincided with a sweeping rise in private school tuition, prompting the city's education...

Jun 29 , 2025 . By BEZAWIT HULUAGER

Central Bank Governor Mamo Mihretu claimed a bold reconfiguration of monetary policy...

Jun 29 , 2025 . By BEZAWIT HULUAGER

The federal government is betting on a sweeping overhaul of the driver licensing regi...

Jun 29 , 2025 . By NAHOM AYELE

Gadaa Bank has listed 1.2 million shares on the Ethiopian Securities Exchange (ESX),...