The pharmaceutical industry is moving to export their products overseas, aiming to reach 15 new markets in east and central Africa in the next two years while increasing annual export revenue by 20pc.

The proposed plans by the Ethiopian Pharmaceuticals Suppliers & Manufacturers Sectoral Association (EPSMSA) seek to increase its production capacity to 70pc and add 20 new pharmaceutical manufacturers including an Additive Pharmaceutical Ingredient (API) facility within five years. It aims to create a sustainable domestic supply chain capable of covering 70pc of medical products and technology.

Last week, a meeting at Eliliy Hotel allowed the companies to present their ambitious association's five-year strategy. The conclave saw the presence of Minister of Health, Mekdes Daba (MD) who was appointed to the position in February alongside Minister for Planning and Development Fitsum Assefa (PhD), State Minister of Health Firehiwot Abebe (MD), and State minister of Industry Hassen Muedin.

Mekdes highlighted the significant strides made by the Ministry in reforming the pharmaceutical manufacturing industry, which had been hampered by numerous policy coils. These reforms have been instrumental in boosting the industry's local capacity. She also emphasized that the new macroeconomic reforms are crucial for enabling producers to expand into regional and international markets and achieve self-sufficiency in the domestic market.

She stated the government’s capital investment in health last year amounted to 1.5 billion Br. However, she noted that the heavy reliance on imports has been a persisting issue with most African countries, which consume 25pc of global vaccines but fall short of producing on the continent.

"We have a long way to go."

Representatives from the pharmaceutical supply and regulatory sectors were also present. In his presentation, Tadesse Teferi (MD), CEO and shareholder of Africure Pharmaceuticals Plc, proposed the need to create an export promotion council.

Despite the industry's aspirations, the sector has seen more misses than hits. Tadesse stated that several challenges persist, with most manufacturers facing regulatory hiccups due to the deprivation of meeting quality requirements. He also stated that manufacturers are struggling with low production, poor technological output and regulatory issues.

"Exports have been slim to none," he told Fortune.

The current 14 local manufacturers struggle to meet a mere eight to 12pc of domestic demand, operating at only 20pc capacity due to the different challenges. Tadesse pointed to the underdevelopment of a manufacturing pharmaceutical industry which is grappling with infrastructural and capacity issues, restraining them from exploiting their full potential.

The manufacturers' strategy aims to meet 70pc of local needs by 2030, looking to introduce three new pharmaceutical products and two new medical devices by 2029, while also integrating advanced manufacturing technologies by 2025.

Daniel Waktola, president of the Association, acknowledges the industry's efforts to align with international standards. However, compliance comes with a significant financial burden. "Manufacturers are yet to meet the requirements," he said.

Daniel, manager of Kilitch, a pharmaceutical company with Indian investors as majority owners, conceded that they have managed to export a certain amount to neighbouring countries including Sudan and Djibouti. Kilitch, a notable producer in the domestic market with the ability to produce 90 million vials of injectable medicines annually, is poised to cater to rising demands.

"We're positioned at the threshold of lucrative markets," he said. However, he notes that manufacturers have not been able to penetrate more countries owing to their incapacity of not meeting regulatory requirements of certification specified in the World Health Organization’s (WHO) Good Manufacturing Practice (GMP).

A mere five pharmaceutical manufacturers are GMP-certified, emphasising the need for urgent reforms. Daniel stated the need to enhance capacity to ensure compliance as a necessary condition for pre- and post-approval of export market Marketing Authorization, which is the official approval granted by regulatory bodies for a pharmaceutical product to be marketed and sold in a specific territory.

Last year, Kilitch Estro Biotech Plc, Glocare Pharma Manufacturing Plc, and Pharmacure Plc were among the companies which exported pharmaceutical products.

Less than 12pc of the country's total pharmaceutical stock is supplied by local manufacturers, down from 25pc during their prime. Only 13pc of the 800 types of medicines procured for 10 billion Br were supplied by domestic manufacturers, with the state-owned enterprise Ethiopian Pharmaceutical Supply Enterprise (EPSS) providing 75pc.

Pharmaceutical manufacturing in Ethiopia dates back to 1964 through a joint venture between the government and the British-based Smith & Nephew Associate Plc. The industry has faced numerous challenges over the years, with the shortage of foreign currency being the most conspicuous, driving several companies out of the market.

The Armauer Hansen Research Institute (AHRI) has set an encouraging precedent, completing preparations to issue bioequivalence inspection certificates, a vital step for pharmaceutical exports. Bioequivalence refers to the state where two or more pharmaceutical products have the same rate and extent of absorption into the bloodstream and is essential for approving cost-effective generic drugs.

Collaboratively set up under the auspices of the Norwegian and Swedish branches of Save the Children in the early 1970s, the Institute has over 900 published research papers.

An 11-billion-dollar short- and long-term investment plan for pharmaceutical, vaccine and integrated tool research development has been presented by AHRI. It includes manufacturing diagnostic tools, bioequivalence services, and input development.

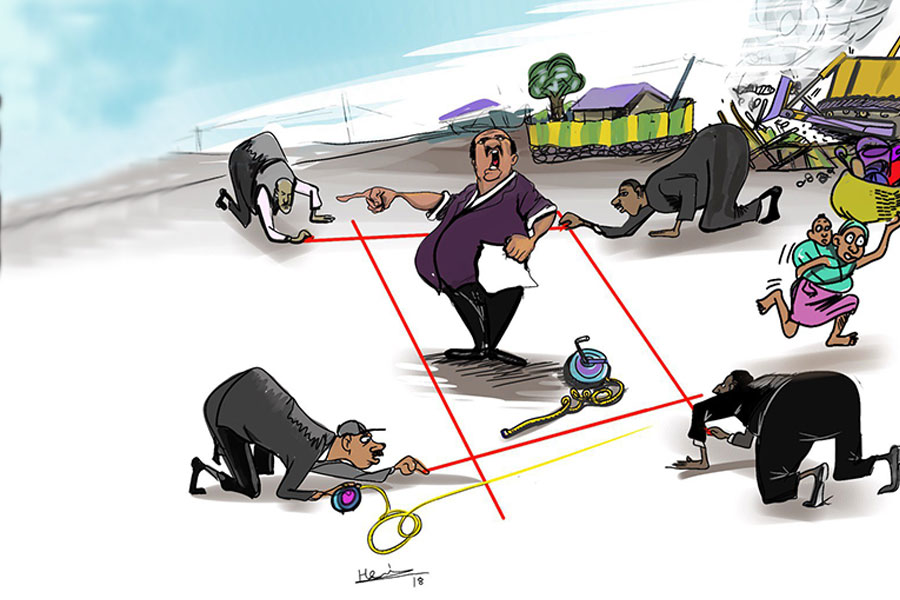

A concerning picture of regulatory hurdles was painted by the Ethiopian Food & Drug Authority (EFDA) amid administrative and economic adversities.

Getachew Gulete, head of drug inspection and regulation at EFDA, states that several regulatory issues persist in the pharma industry, including poor compliance to national pharmacy standards, insufficient capacity covered by poor facilities, and local products not supported by bioequivalence information.

He stated that the impending concerns have kept the country from attaining Maturity Level Three (ML3) from WHO, an evaluation tool that checks regulatory functions against a set of more than 260 indicators. This would have confirmed that a stable, well-functioning, and integrated regulatory system is in place. Six African countries—Tanzania, Ghana, Nigeria, Zimbabwe, Egypt, and South Africa—were able to attain ML3, while Ethiopia is awaiting an evaluation session in November.

Getachew also stressed the pervasive surge of contraband pharmaceutical supplies illegally imported to the country. In last year’s six-month report, EFDA reported that 107 million Br worth of medicines were disposed of for being unauthorised, outdated, substandard, or illegally imported.

Recent research conducted by universities in Bahir Dar and Gonder reveals a troubling trend that nearly 22pc of medicine samples tested across sub-Sahara Africa failed quality tests. These medicines were found to be substandard, falsified, or unregistered, presenting serious risks to public health.

The study uncovers the vulnerability of the pharmaceutical supply chain, which relies heavily on imports, with over 85pc of the market being met by foreign suppliers. India, the Netherlands, and Belgium are the largest sources, but the intricate and fragmented supply chains create opportunities for illicit products to enter the market.

While import substitution is deemed essential for sustainability by officials, experts such as Messay Woldemariam, deputy director of AHRI emphasise the need for comprehensive health sector reform, warning of a long road before Ethiopia can become self-sufficient in pharmaceutical supply, as local industries are yet to sufficiently produce even basic commodities.

With the majority of health financing being aid-funded, Getachew observes a combination of import substitution and export orientation as crucial. He stated the need for transparent and accountable policies as vital to building trust between the government and the local pharmaceutical industry.

"The industry is set to grow in a few years," he said.

PUBLISHED ON

Oct 06,2024 [ VOL

25 , NO

1275]

Radar | Mar 23,2019

Agenda | Aug 17,2025

Life Matters | Aug 27,2022

Radar | Nov 09,2019

Fortune News | Jan 22,2022

Radar | May 25,2019

News Analysis | Jul 07,2024

Fortune News | May 23,2021

Viewpoints | Nov 26,2022

Editorial | May 02,2024

Dec 22 , 2024 . By TIZITA SHEWAFERAW

Charged with transforming colossal state-owned enterprises into modern and competitiv...

Aug 18 , 2024 . By AKSAH ITALO

Although predictable Yonas Zerihun's job in the ride-hailing service is not immune to...

Jul 28 , 2024 . By TIZITA SHEWAFERAW

Unhabitual, perhaps too many, Samuel Gebreyohannes, 38, used to occasionally enjoy a couple of beers at breakfast. However, he recently swit...

Jul 13 , 2024 . By AKSAH ITALO

Investors who rely on tractors, trucks, and field vehicles for commuting, transporting commodities, and f...

Oct 11 , 2025

Ladislas Farago, a roving Associated Press (AP) correspondent, arrived in Ethiopia in...

Oct 4 , 2025

Eyob Tekalegn (PhD) had been in the Governor's chair for only weeks when, on Septembe...

Sep 27 , 2025

Four years into an experiment with “shock therapy” in education, the national moo...

Sep 20 , 2025

Getachew Reda's return to the national stage was always going to stir attention. Once...