Commentaries | Jul 25,2020

A father of four, Seifu Worako caught a bright glimpse of hope when Yirgalem Integrated Agro-Industrial Park opened earlier this year. A company based in the Park, Duoley Food Processing Plc, producer of the Jojo flavoured milk brand, presented a golden opportunity for Seifu and others like him to generate additional income.

Dwelling near the Park located in Sidama Regional State, over 400Km south of Addis Abeba, Seifu took a loan of almost one million Birr to upgrade his dairy farm and improve output, acquiring nine additional dairy cows, bringing the size of his herd to over 60. Part of a cooperative of five farmers, Niku Modern Milk Production, Seifu got off to a good start.

Duoley would buy as much as 700 litres of milk a day from the cooperative, paying between 28 Br and 32 Br for a litre. Though the market offers four Birr more for a litre, the sheer volume of demand from the company was an offer too tempting to ignore. Seifu saw some of his neighbours shifting from other businesses to milk production.

Alas, the good times did not last long.

Duoley's demand has fallen sharply, with the company sometimes buying as little as 100lt of milk a day from the cooperative, leaving Seifu with a huge surplus.

Problems with sugar supply from the state-owned producers and transportation hurdles on the imports of raw materials and additives have become a bottleneck for the company, which began operation in March this year. Established with six million dollars in initial investment, Duoley has a daily capacity of packaging up to 60,000 litres of flavoured milk. It has only been able to meet a third of this at best.

Production has fallen even lower now due to the issues Duoley faces in sourcing raw materials. Sugar remains out of reach.

The processing plant consumes around 100 quintals of sugar a month, though the supply has all but dried up, a situation that has forced the management sometimes to skip buying milk from farmers.

Neither do cafes and hotels in the nearby town have much demand for the milk product Douley stopped buying. This leaves Seifu confused. When an agro-processor sets up in rural areas, farmers are usually the first to cherish it. They have reasons.

Most of them, including Seifu, believe agro-processing plants would mean a dependable buyer for their product, besides creating employment for the youth and women in their communities. Both imply disposable income and an opportunity to increase output. In the case of Seifu and members of his community, it was an opportunity that vanished in a short stretch of time.

Their disappointment is the result of a combination of issues.

In many cases, when agro-processing companies begin operations, they tend to overlook the supply aspect, not giving enough attention to integrating with farmers or suppliers. Some set up plants with the hope of getting inputs without interruption and quality issues. They also tend to ignore the impacts of external factors, including logistics hurdles and foreign currency crunches.

Dometically produced fruit juice products are slowly making it to supermarket shelves, though imported products still dominate the market.

The former holds for Duoley Food Processing Plc, a fact attested by its shareholder and general manager, John Snow.

“We're almost not producing now,” Snow told Fortune.

The company has overhead costs of around four million Birr a month, including salaries for 120 staff members.

“We really need government support.”

It appears that the focus of the government, at least for now, is attracting new investors to swarm the many industrial parks mushroomed across the country.

Aspiring to reduce reliance on imports and capitalise on agriculture and pastoralism, the lifelines for the vast majority of the population, the government has inaugurated three agro-industrial parks, including Yirgalem, over the past six months. Officials hope the move would help the country substitute imports that cost 14 billion dollars last year, with consumer items such as wheat and edible oil accounting for around a quarter of this.

Bure Integrated Agro-Industrial Park, located in Amhara Regional State, and Bulbula Integrated Agro-Industrial Park in Oromia Regional State, have been opened with grand claims of the direct and indirect jobs these industrial estates would create, expected to reach 200,000.

If everything had gone according to plan, Baeker Integrated Agro-Industrial Park in Tigray Regional State would have been the fourth park to be inaugurated. Construction began in 2018 but was interrupted shortly after.

Fourteen areas have been identified to construct agro-industrial parks throughout the country, disclosed Aschalew Tadesse, promotion director at the Ethiopian Investment Commission.

“These industrial parks are quite different from the manufacturing ones,” said Aschalew. “The backward and forward linkage is great on these.”

But this shows that the emphasis has been on expansion while overlooking the value of alleviating the troubles of those that have begun production in the inaugurated parks and suppliers around them.

Seifu's predicament is a living testament to the work remaining in improving the Ethiopian agro-processing industry.

He spent heavily on cattle feed, which costs around 1,150 Br a quintal, hoping to increase milk production and supply to Duoley. It worked, and each of his cows would yield up to 20 litres of milk a day, not a bad daily yield compared to the global average of 34 litres. Now faced with a milk surplus and unmanageable costs for feed, reaching as high as 200,000 Br a month, Seifu has resorted to limiting feed consumption.

“We really are confused with our overproduction of milk now,” he told Fortune. “Sometimes we make butter out of it, and sometimes we just spill it.”

The cows produce half as much, but the surplus remains. He also has to pay salaries to his workforce of eight, leaving him bitterly disappointed with his investment.

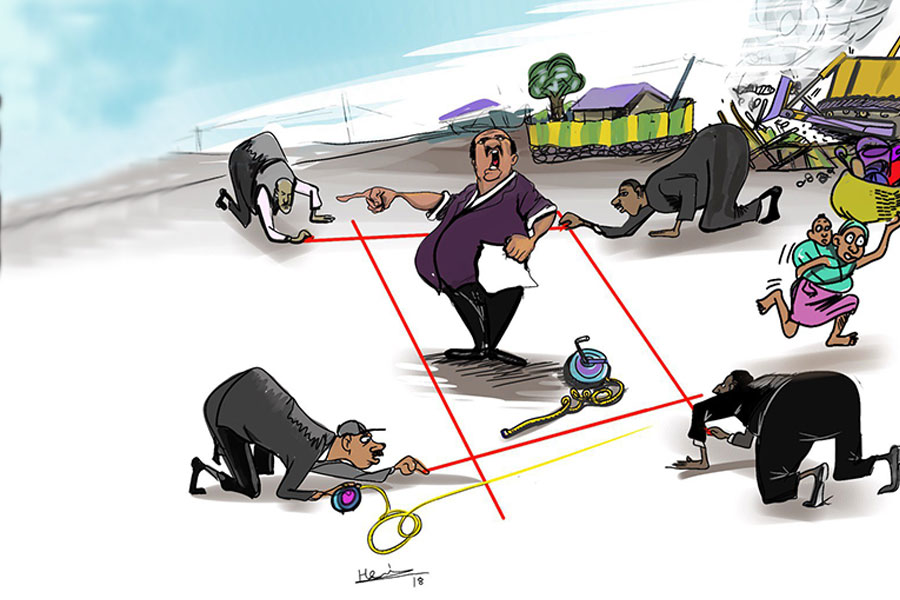

A lack of access to the market is one of the biggest challenges smallholder farmers face in most parts of Ethiopia. Incidents abound where farmers were forced to dispose of their output, unable to find buyers. Partly, this happens due to lack of infrastructure, but it is also an outcome of poor integration with farmers.

Agro-processing industries spend millions of dollars to buy an input that is available locally, a regrettable truth that could have been avoided if enough attention had been given to backward integration before setting up the parks and plants, according to Demis Chanyalew (PhD), an agricultural economist with over three decades of experience. He has also authored a book on the history and state of Ethiopia's economy.

Backward linkage works better if transportation services are available to farmers or the agro-processing plant is built near the farming area and has adequate storage facilities. Equally important is access to market information that enables farmers to identify business opportunities and plan accordingly, though this too lacking. It appears that those in the agro-processing sector are far from realising such critical aspects of local sourcing.

Investors that have taken the risk have ended up disappointed.

Hilina Belete is one of these pioneering investors left with all but frustration. Running a company that produces enriched foods, including Plumpy'nut, a peanut paste used to treat malnutrition, she has tried to link directly to farmers producing peanuts through their union. But her experience has not been pleasant.

Hilina Enriched Foods Plc processes 15,000tn of raw peanuts monthly, of which 85pc was imported from abroad last year. It has resorted to sourcing from a local supplier that collects from farmers and delivers the input for processing at the plant. It was not easy to receive the inputs uninterruptedly, however. Dealing with farmers on payment has also been challeging, particularly if her company rejects their produce because of quality issues, a common incident at the moment.

"There has been a huge gap in quality, while the process of sourcing was time-taking and tiresome," Hilina told Fortune. She added there were times when the company sourced half of its input needs locally, but keeping up the momentum has not been easy.

Agro-processors involved in the processing of fruits are facing similar trials.

It may have been portended that Ethiopia is endowed with a climatic condition conducive to fruit production. The experience of Great Abyssinia Plc is to the contrary.

The company bottles the Israeli brand Prigat Juice at its 25,000sqm plant in Sendafa, Oromia Regional State, for the last 13 years, with a daily average of 6,000lt of juice. Despite the longevity and relative success, the company still imports the necessary concentrates, preservatives, and flavouring from Israel – spending two million dollars annually and not using any local fruits.

"There is no local farm that can supply fruits without any interruption," says Amare Kassa, managing director of Great Abyssinia, a company incorporated in 2004, with 246.7 million Br registered capital.

According to Amare, much work has to be done on large-scale farming and technology to produce the juice concentrates locally.

“Farming comes first above all, and agro-processing work should get even much more focus,” he said. "We want to cultivate our own fruit in the future."

Great Abyssinia awaits the provision of land from the authorities.

Meanwhile, demand for products like Prigat is growing popular. The same is true for the products of Duoley, Jojo Milk. Retailers in Addis Abeba stock their shelves with locally produced items than ever. Consumers are also developing an appetite for local products. A glimpse at one of the biggest supermarkets in Addis Abeba attests to the new development in the market.

The stock of Shoa Supermarket consists of over 23,000 different products, while it is made up almost entirely of imports. However, Getahun Abate, manager of Shoa's branch on Africa Avenue (Bole Road), near Wello Sefer, observes that more and more local products, particularly fruit juice beverages, are making their way into the market.

Despite this, there are still glaring issues with quality and consistency.

“Initially, they provide you with the good quality," he told Fortune. "Gradually, you'll see it declining.”

The team at Shoa conducts its own testing to ensure the quality of the items making to its shelves is acceptable. Many local products pass government tests but fail Shoa's in-house inspections.

"Packaging is also another issue – many local products lack attractive packaging, a hallmark of modern consumerism," says Getahun.

It is a view shaped by keen observation of how the market is poorly served on sufficient supplies and inconsistent production both in quality and form.

PUBLISHED ON

Sep 04,2021 [ VOL

22 , NO

1114]

Commentaries | Jul 25,2020

Fortune News | May 21,2022

Fortune News | May 14,2022

Fortune News | Mar 19,2022

Radar | Aug 28,2021

Editorial | Apr 01,2023

Life Matters | Jun 15,2019

Radar | Aug 21,2021

Fortune News | May 23,2021

Dec 22 , 2024 . By TIZITA SHEWAFERAW

Charged with transforming colossal state-owned enterprises into modern and competitiv...

Aug 18 , 2024 . By AKSAH ITALO

Although predictable Yonas Zerihun's job in the ride-hailing service is not immune to...

Jul 28 , 2024 . By TIZITA SHEWAFERAW

Unhabitual, perhaps too many, Samuel Gebreyohannes, 38, used to occasionally enjoy a couple of beers at breakfast. However, he recently swit...

Jul 13 , 2024 . By AKSAH ITALO

Investors who rely on tractors, trucks, and field vehicles for commuting, transporting commodities, and f...

Oct 11 , 2025

Ladislas Farago, a roving Associated Press (AP) correspondent, arrived in Ethiopia in...

Oct 4 , 2025

Eyob Tekalegn (PhD) had been in the Governor's chair for only weeks when, on Septembe...

Sep 27 , 2025

Four years into an experiment with “shock therapy” in education, the national moo...

Sep 20 , 2025

Getachew Reda's return to the national stage was always going to stir attention. Once...