Radar | Apr 26,2019

May 11 , 2019

By KALAEB GIRMA ( FORTUNE STAFF WRITER )

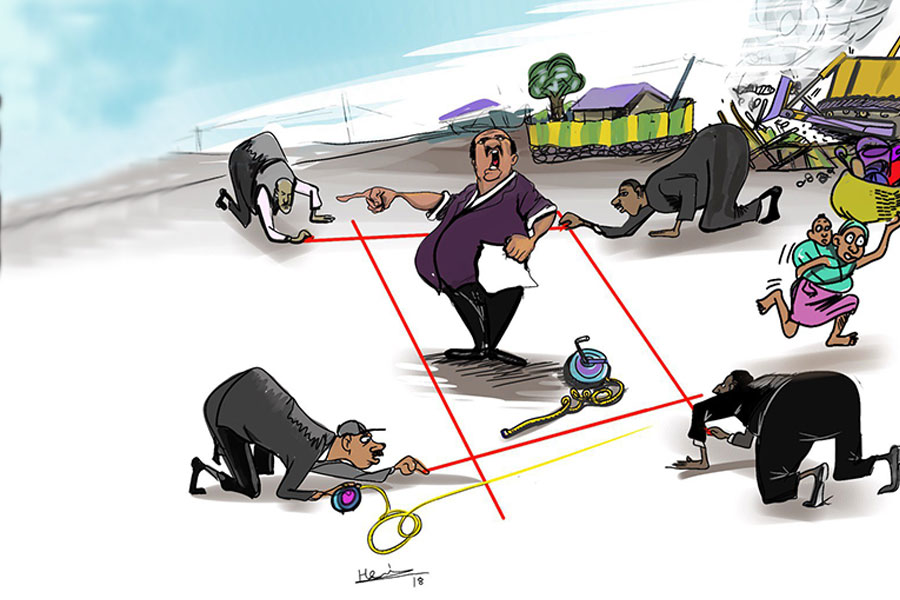

An eight-member committee will begin auditing a 1.7-billion-Br "failed project" that was awarded to the Metals & Engineering Corporation (MetEC) this coming week.

An eight-member committee will begin auditing a 1.7-billion-Br "failed project" that was awarded to the Metals & Engineering Corporation (MetEC) this coming week. An eight-member committee will begin auditing a 1.7-billion-Br "failed project" that was awarded to the Metals & Engineering Corporation (MetEC) this coming week.

The Manufacturing Industry Steering Committee of parliament formed a team to assess the 2015 project awarded to set up 37 manufacturing workshops in four regions of the country as well as the capital. The team is expected to submit its findings within three months.

The committee was formed with two members each from the Ministry of Industry & Trade, Federal Technical & Vocational Education & Training Agency, Metal Industry Development Institute and the Federal Small & Medium Manufacturing Agency.

“The decision to audit the project was taken after it failed to meet its goals,” said Daniel Olani, deputy general director at the Federal Small & Medium Manufacturing Development Agency.

The committee will audit the technical, human and financial status of the workshops. It will assess how many existing machines there are in the workshops and what their specification are, how many of them are functional and how many additional machines are needed.

The committee will also audit the amount of revenue these workshops have generated thus far, the amount of debt outstanding and the number of employees they have and youth groups that are working in the workshops.

“While the project brought together many federal and regional offices, it was spearheaded by MetEC,” said Daniel.

Launched four years ago, the project aimed at creating fully equipped manufacturing workshops for youth groups to work under a lease financing scheme. They were planned for the manufacturing of spare parts for agricultural equipment, vehicles and machinery under medium manufacturing enterprises, which are classified as firms that employ between 30 and 100 people and have a capital of 20 million Br.

This specific project aimed to create job opportunities for an average of 101 people at each workshop.

Currently, there are around 15,000 small and medium manufacturing industries engaged in the production of chemicals, construction materials and textile industry.

MetEC, under its Hibret Manufacturing & Machine-Building Industry, took both the civil work and installation of the machines. There were in all 37 workshops built at an average cost of 47 million Br.

The Tigray Regional state had 12 workshops, seven in Oromia and Amhara regional states each, and the SNNPR and Addis Abeba had five each. MetEC, after completion of the project, transferred the workshops to the regional governments and the city administration.

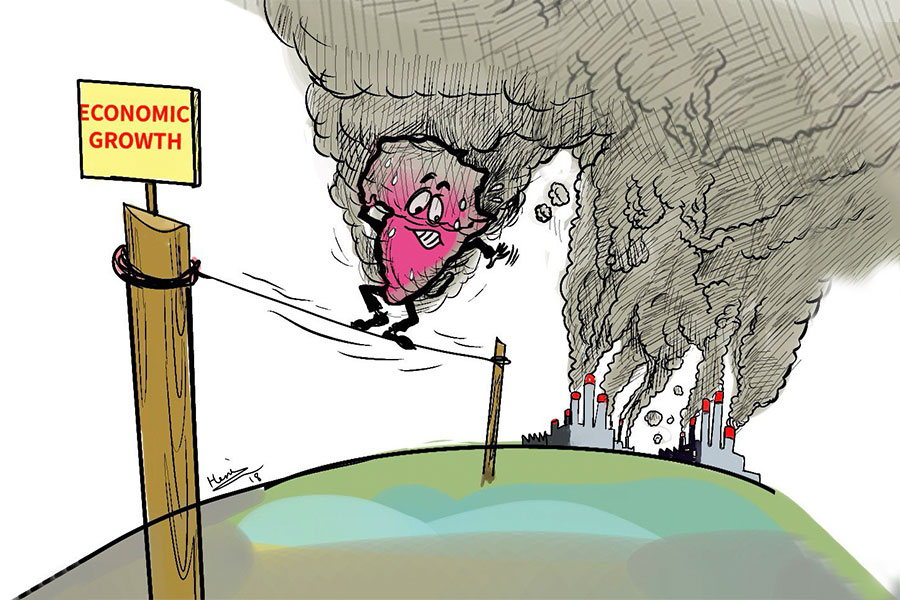

“The project had a noble cause, and it was the first of its kind,” said Daniel. “It was part of the government’s plan for industrial transformation from an agriculture-led economy.”

Except for Addis Abeba that paid up front, all the four regions took on loans from the Commercial Bank of Ethiopia.

“The project didn’t go according to the plan,” says Daniel. “Almost all of them were incurring losses, while the interest at the bank was accumulating.”

MetEC, by not delivering all of the machines or submitting them with the wrong specifications, failed to create promised market linkages and failed to aid youth groups learn to operate the machines, which combined led to the project’s failure, claims Daniel.

“The lack of a feasibility study before the launch of the project was a major bottleneck,” he says. “There should have also been a feasibility study.”

“Just because projects are formulated and huge amounts of funds are allocated, success is not a guarantee, especially in the manufacturing sector,” said Bisrat Addisu, an expert in the field of mechanical engineering for a decade and owner of B&R Nail Manufacturing Plc.

He argues there should have been a lot of work done from product design to market analysis before the project commenced.

“The manufacturing sector is an area that demands high precision and expertise,” he said.

PUBLISHED ON

May 11,2019 [ VOL

20 , NO

993]

Radar | Apr 26,2019

Fortune News | Jun 14,2020

Fortune News | Nov 30,2019

Radar | May 04,2019

Radar | Apr 13,2019

Radar | Jun 30,2024

Radar | Feb 02,2019

Fortune News | Oct 13,2024

Radar | Feb 12,2022

Radar | Dec 28,2019

Dec 22 , 2024 . By TIZITA SHEWAFERAW

Charged with transforming colossal state-owned enterprises into modern and competitiv...

Aug 18 , 2024 . By AKSAH ITALO

Although predictable Yonas Zerihun's job in the ride-hailing service is not immune to...

Jul 28 , 2024 . By TIZITA SHEWAFERAW

Unhabitual, perhaps too many, Samuel Gebreyohannes, 38, used to occasionally enjoy a couple of beers at breakfast. However, he recently swit...

Jul 13 , 2024 . By AKSAH ITALO

Investors who rely on tractors, trucks, and field vehicles for commuting, transporting commodities, and f...

Oct 4 , 2025

Eyob Tekalegn (PhD) had been in the Governor's chair for only weeks when, on Septembe...

Sep 27 , 2025

Four years into an experiment with “shock therapy” in education, the national moo...

Sep 20 , 2025

Getachew Reda's return to the national stage was always going to stir attention. Once...

Sep 13 , 2025

At its launch in Nairobi two years ago, the Africa Climate Summit was billed as the f...