Radar |

A few years ago, a week did not go by without a new plant for bottled water kicking off production. Those roaring times have come to a screeching halt. Consumers are noticing. A two-litre bottle of mineral water, with a 13 Br price tag at kiosks a few months ago, jumped to 20 Br. The volatility in the consumer market only exposes the dilemma the industry faces. Like most other manufactured goods, the sector suffers from an agonising shortage of foreign currency. While the water in the bottles is sourced locally, the materials used to blow up the plastic packaging need to be imported.

Polyethylene terephthalate (PET), a derivative of oil and natural gas, is a vital ingredient for bottled water and food, beverage, or consumer product that uses plastic as packaging. The entire plastic manufacturing sector, which has produced 400,000tn in five years and employs around 11,000 workers, is battered and operates at below two-thirds of its capacity. While a foreign currency shortage is a regular headache for these manufacturers, the storm is harsher these days. The most recent disaster to strike the supply chain they depend upon is skyrocketing fuel prices in the international market.

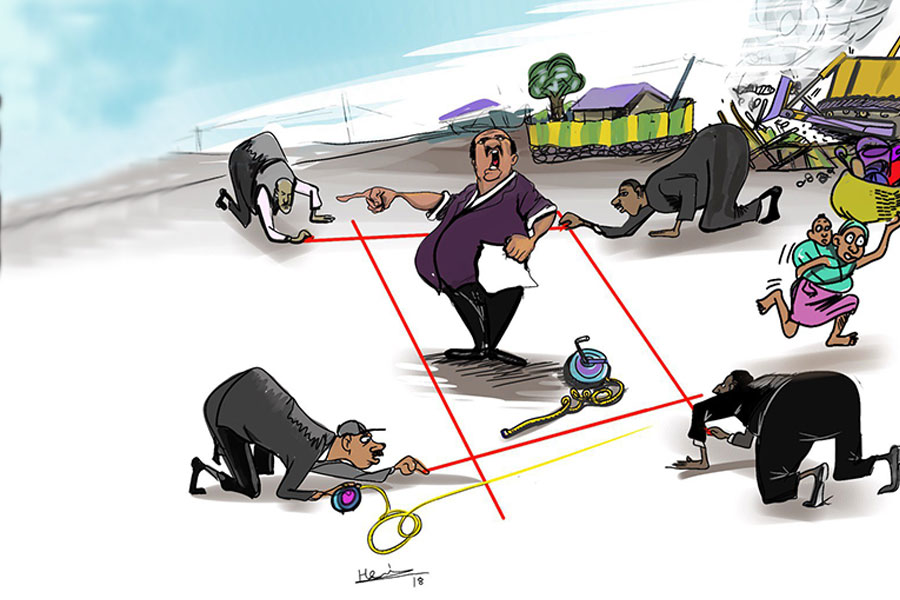

The Ethiopian Plastic & Rubber Manufacturers Association urges federal authorities for a solution. It insists the National Bank of Ethiopia (NBE) allocates sufficient foreign currency to save the industry from the risk of total collapse. Some others see a golden opportunity to rid consumers of their addiction to highly environmentally polluting materials like plastic bags and discourage it further, as countries like Kenya and Rwanda have done. Stuck in the middle are millions of consumers in a seemingly endless struggle with inflation and the thousands of workers employed by the plastic manufacturing industry (and beyond) whose livelihoods are hanging by a thread.

You can read the full story here

PUBLISHED ON

Apr 02,2022 [ VOL

23 , NO

1144]

Radar |

Commentaries | Sep 17,2022

Fortune News | Nov 30,2019

Fortune News | Nov 25,2023

Commentaries | Aug 03,2025

Radar | Nov 27,2018

Agenda | Mar 20,2021

Radar | Jan 07,2023

Radar | Sep 14,2025

Viewpoints | Jun 25,2022

Dec 22 , 2024 . By TIZITA SHEWAFERAW

Charged with transforming colossal state-owned enterprises into modern and competitiv...

Aug 18 , 2024 . By AKSAH ITALO

Although predictable Yonas Zerihun's job in the ride-hailing service is not immune to...

Jul 28 , 2024 . By TIZITA SHEWAFERAW

Unhabitual, perhaps too many, Samuel Gebreyohannes, 38, used to occasionally enjoy a couple of beers at breakfast. However, he recently swit...

Jul 13 , 2024 . By AKSAH ITALO

Investors who rely on tractors, trucks, and field vehicles for commuting, transporting commodities, and f...

Oct 11 , 2025

Ladislas Farago, a roving Associated Press (AP) correspondent, arrived in Ethiopia in...

Oct 4 , 2025

Eyob Tekalegn (PhD) had been in the Governor's chair for only weeks when, on Septembe...

Sep 27 , 2025

Four years into an experiment with “shock therapy” in education, the national moo...

Sep 20 , 2025

Getachew Reda's return to the national stage was always going to stir attention. Once...