Derbe Asefa, a farmer from Asambitu village in Sinana Wereda of Bale Zone, Oromia Regional State, cultivates 13ha of land with wheat and barley in the spring and summer seasons.

A father of four, Derbe cultivates his farm during May and July and harvests the crops during the months of August and October every year. For the entire process, he spends 40,000 Br a year.

For years he had been struggling with crop loss since he was using less advanced farming mechanisms and tools. He had also been losing a significant amount of crops to damaging rainfall since he was not harvesting the crop on time due to following traditional farming techniques. To collect the crop, he was hiring other farmers who can harvest 1,500Sqm of cropland a day.

On top of that, a significant portion of his farmland had sat idle, because he did not have the necessary agricultural machinery to manage his homestead properly.

This triggered him to start using tractors and combiner harvesters, which he leased for 80 Br a quintal. He has now been using agricultural machinery for the past two decades.

Two years ago, Derbe along with his neighbour bought a combiner harvester through lease financing offered by Oromia International Bank. The Bank lent them the money after they presented 1.2 million Br or 30pc of the total cost of the machine.

The combiner harvester was imported by Kaleb Services Farmer's House Plc, a local agricultural machinery importer. The machine enabled Derbe and his neighbours to harvest 20ha of cropland a day.

After he bought the machine, he began harvesting his crops at a more appropriate time, saving more money, and started to earn 700,000 Br a year by leasing the machine to other farmers.

Inspired by this, Derbe decided to buy an additional combiner harvester this year.

When he approached some banks to borrow the money, however, he was surprised that his attempt was in vain.

The banks told him that they could not offer a new loan due to the foreign currency crunch and liquidity crisis, according to Derbe.

He finally landed on a deal with Ethiopian Capital Goods Finance Business, aka Ethio-Lease, after his friend told him about the company. Ethio-Lease has thus far imported and distributed 42 tractors and 16 combiner harvesters, covering 70pc of the total cost of the imported combiner harvester.

He received his new combiner harvester from the company two weeks ago in Shashemene at the premises of Kaleb Services Farmer's House.

“This was a great opportunity for me,” Derbe told Fortune.

Ethio-Lease, which is the subsidiary of African Asset Finance Company (AAFC), secured a license from the National Bank of Ethiopia to operate a leasing company in July of 2019 as the first foreign-owned entity in the business.

The company was registered with a capital of 400 million Br to start the agricultural equipment leasing business. It buys the agricultural machinery from its sister company, AAFC, using the foreign currency to import through a duty-free privilege, and leases them to its customers for three-year periods.

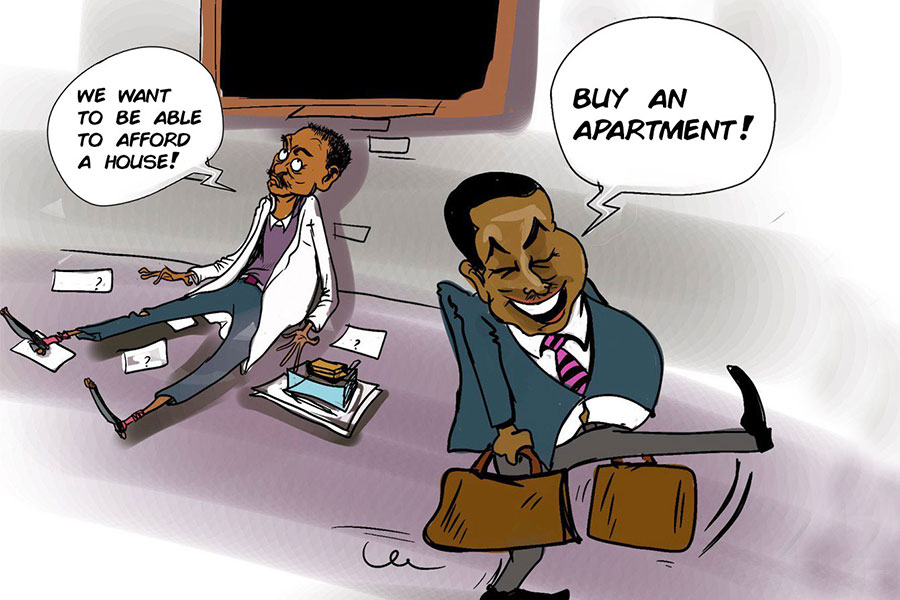

Girum Tsegaye, CEO of Ethio-Lease, gives the key of the combiner harvester to farmer Derbe Assefa.

Along with leasing the machinery, Ethio-Lease offers maintenance, insurance, operator training, certification and deployment services. It works with local distributors, namely Kaleb Services Farmer's House and Motor & Engineering Company of Ethiopia S.C. (MOENCO), to offer the machinery to farmers.

Since the agricultural machinery is imported with a duty-free privilege, it has received heavy demand from farmers as they can access it at a comparatively fair price, according to Girum Tsegaye, CEO of the company and former vice president of Hibret Bank.

Motivated by the huge demand, the company has allocated 200 million dollars for the next year, according to Girum.

Last year, the Ministry of Finance has exempted all types of taxes and duties on agricultural machinery hoping to support the sector that has been characterised as inefficient. While having an 80pc agrarian population, the sector has not been as productive as it should be.

The Ministry of Agriculture has conducted an assessment to find out the bottlenecks in the sector, according to Bereket Forsido, agricultural mechanisation director at the Ministry, which found out that agricultural mechanisation stood at 0.01pc in 2015.

Equipped with over 15 million hectares of arable land or 13pc of total land, just under 10pc of the total arable land of Ethiopia is mechanised now. The total irrigated area of Ethiopia is estimated to be 138,000ha.

The assessment was followed by a strategy drafted in 2015 that showed the sector was characterised by little access to agricultural technology, higher costs of the equipment due to tariffs levied on imported agricultural equipment, and a low number of agricultural equipment importers and suppliers. It also pointed to spare parts and after-sales service insufficiency, lack of skilled manpower, and lack of research and development.

The tariff was among the main problems that challenged the agricultural sector, according to Bereket.

"Taxes that were levied on the importers amounted to 35pc to 45pc of the total price of the equipment," he says.

Based on the findings of the assessment, the Ministry of Agriculture alongside the Agriculture Transformation Agency (ATA) initiated a tax reform policy last year to exempt agricultural equipment from duties and taxes.

The Ministry of Agriculture then issued a proclamation on August 7, 2019, and a directive in April 2020 to allow duty-free imports of agricultural machinery. The Ministry of Finance approved the imports of agricultural machinery, irrigation technology and animal feed equipment to be tax and duty-free in April.

Since the legislation of the law that fully waived the taxes and tariffs, the number of agricultural machinery importers has increased by 30pc.

Between this April and June, 52 new agricultural equipment importers secured a license to engage in the sector. Before the tax reform, there were 120 licensed importers, though many of them were inactive.

This created a huge demand for agricultural machinery, according to Abraham Endrias, managing director of Green Agro-Solution Plc, an agricultural mechanisation service provider that was established six years ago and runs agricultural mechanisation service for smallholder farmers in Bale Zone, Oromia Regional State.

It used to be very hard to easily access foreign currency from financial institutions to import the mechanisation machinery, according to Abraham.

“But now there is fairly sufficient access to loans and foreign currencies as foreign lease-finance companies are coming to the sector," he said.

Green Agro-Solution is currently expanding its foothold to Southern Nations, Nationalities & People's (SNNPR), Amhara and Somali regional states to commercialise the huge demand recently created by the duty-free import arrangements.

Kaleb Services Farmer's House had also been challenged due to the cash shortage that began last year and higher costs to import in large amounts. But now the volume of its imports have increased, according to Michael Tesfaye, sales manager at the company.

Importers had been required to put their imported equipment in bonded warehouses until the customs commission processed the taxes, which used to take almost 120 days.

This is no longer the case at this moment, according to Michael.

The ATA is also working on establishing 10 agricultural mechanisation service centres. Of them, four are in Oromia, three in Amhara, two in SNNPR, and one in Tigray regional states.

The Agency spends four million Birr for the design and setup of a single mechanisation centre, which sits on two to three-hectare plots. ATA, which is planning to establish set up 10 new mechanisation centres this budget year, granted eight of the centres to farmer cooperative unions and the remaining two to private enterprises.

Seventy percent of the total cost to construct the centres, 63.7 million Br, will be covered by the Agency and 30pc by the grantees.

The aim of establishing the centres is to improve the agricultural mechanisation of the country, according to Chimdo Anchala (PhD), senior director of production and productivity projects at the Agency, by giving farmers easy access to the equipment and services in their localities to enhance productivity, harvest quality, and smallholder farmers’ livelihoods.

“The project has motivated many mechanisation service providers to import more equipment and expand their services,” he said.

Farmers had been facing severe problems emanating from lack of mechanisation services, such as machinery leasing, the availability of spare parts and maintenance, according to Getachew Eshetu, executive director of Damot Farmer Cooperative Union, in Bure, West Gojjam, Amhara Regional State.

"The prices of the machinery were high, and farmers couldn’t get as much as they need," Getachew said.

Damot Cooperative Union, which has 173,000 farmers and 77 primary cooperatives union members, was awarded the agricultural mechanisation centre in Bure.

“There are many alternative service providers through which the farmers can obtain mechanisation services,” says Getachew. “This has pushed the farmers to utilise more equipment and the entrance of many businesses involved in the sector.”

The involvement of more businesses in the mechanisation service sector reduced the financial problems that were common to agricultural mechanisation programmes, according to Getachew.

However, the higher interest rates are still challenging farmers and machinery importers.

Members of the Damot Farmer Cooperative Union used to get lease financing from the Development Bank of Ethiopia at a 9.5pc interest rate. Now they access it from private companies at 11pc, according to Getachew.

“This posed serious challenges from sufficiently utilising mechanisation machinery,” he said.

Many enterprises are shifting from DBE to private lease-finance institutions in order to import machinery, since the Bank has not been able to provide them with foreign currency as quickly and sufficiently as they need, according to Getachew.

But the higher interest rate is another serious problem to the sector, according to Abraham.

Little financial access from the Development Bank is still the main problem that is challenging the mechanisation project, according to Chimdo.

For the just ended fiscal year, the Development Bank of Ethiopia committed half a billion Birr to agricultural mechanisation leasing projects. Farmers pay an eight percent interest rate to borrow from DBE.

As the smallholder farmers do not require much money, DBE can easily lend to them if they fulfill the criteria, according to Natnael Hailu, strategic communications and change director at the Bank.

"The problem happens in the manufacturing sector as borrowers ask for much more money," he says.

The Ministry of Agriculture wants to increase agricultural mechanisation to 50pc after five years and to 90pc by the end of 2030.

This seems unpractical, according to Mohammed Aman, assistant professor of agricultural economics at Haramaya University.

"Most of the arable land in the country is owned by smallholder farmers who cannot afford the prices of the machinery," says Mohammed. “The farmers might not even need heavy machinery but rather light agricultural machinery they can easily operate.”

The mechanisation of the agricultural sector is related to industrialisation and growth in the manufacturing and service sectors, according to Mohammed.

“Growth in the manufacturing sector results in domestic production of mechanised equipment,” he says.

Mechanisation brings unemployment, and if the other sectors were growing, unemployed people who were previously in the agricultural sector would be employed in the manufacturing and service sectors, according to him.

Second-hand agricultural machinery should be allowed to be imported duty-free in order that farmers can access equipment at lower prices, according to Mohammed.

Establishing vibrant farmer cooperative unions could comparatively enable the farmers to easily own the machinery and increase their bargaining power in selling their products, according to Mohammed.

Derbe now fully understands the merits of mechanisation and plans to purchase more machinery. He is planning to buy a tractor from Ethio-Lease within eight months. The tractor will enable him to plough one hectare of land within an hour, down from two and a half days by the traditional technique.

PUBLISHED ON

Aug 16,2020 [ VOL

21 , NO

1059]

Radar | May 04,2024

Fortune News | Jun 29,2024

Fortune News | May 13,2023

Radar | Nov 14,2020

Fortune News | Jun 19,2021

Dec 22 , 2024 . By TIZITA SHEWAFERAW

Charged with transforming colossal state-owned enterprises into modern and competitiv...

Aug 18 , 2024 . By AKSAH ITALO

Although predictable Yonas Zerihun's job in the ride-hailing service is not immune to...

Jul 28 , 2024 . By TIZITA SHEWAFERAW

Unhabitual, perhaps too many, Samuel Gebreyohannes, 38, used to occasionally enjoy a couple of beers at breakfast. However, he recently swit...

Jul 13 , 2024 . By AKSAH ITALO

Investors who rely on tractors, trucks, and field vehicles for commuting, transporting commodities, and f...

Jun 28 , 2025

Meseret Damtie, the assertive auditor general, has never been shy about naming names...

Jun 21 , 2025

A well-worn adage says, “Budget is not destiny, but it is direction.” Examining t...

Jun 14 , 2025

Yet again, the Horn of Africa is bracing for trouble. A region already frayed by wars...

Jun 7 , 2025

Few promises shine brighter in Addis Abeba than the pledge of a roof for every family...