Uniform standards and inspections on imported and locally manufactured agricultural machinery are nearing sight following the agreement to establish agricultural mechanisation centre. The centre is expected to foster a training hub for maintenance.

It rests on three-hectare land around the Kality area with a 14.67 million dollar grant secured from the South Korean government.

The memorandum of understanding (MoU) was signed between the Ministry of Agriculture and the Korean Ministry of Trade, Industry & Energy in February.

Officials hope to enhance the inspection capacity through agricultural technologies that have prevented the Ministry from enforcing over 250 standards.

According to Bereket Forsido, agricultural mechanisation director at the Ministry, increasing production through mechanised farming, quality inspection and capacity building is the primary target sought to be addressed by the centre.

Bereket said they plan to develop a quality testing facility and train 2,000 farmers and 200 technicians and operators; engagements in reverse engineering and research tailored to farming technologies are essential to increase production.

“We’re focused on building technical capacity to produce a surplus,” he told Fortune.

Bereket said operation and maintenance branches at Bure, Gimbichu and Halaba towns over-sighted by the centre, will be launched to ease the burden and make technical assistance more accessible to farmers.

The Ministry plans to use facilities provided by the Ministry of Labour & Skills to train recruited engineers and technicians until the centre becomes operational end of 2026. It is expected to enrol 50 maintenance technicians and 60 engineers to work in the testing, research and design departments.

Substandard technologies and reduced technical capacity are cited as major setbacks for mechanised farming, which covers less than one percent of the arable land area.

Ayenew Lema, technical officer at one of the state-owned farms, believes the technical inspection centres will shield mechanised farms from purchasing substandard machinery and incurring huge financial losses.

According to Ayenew, the absence of technically equipped institutions to compel importers and producers to meet standards led to spending limited foreign currency on substandard machinery.

“This will restrain those who want to capitalise on the technical inadequacy,” he told Fortune. "It’s common to see idle machinery due to technical deficiency."

A study conducted by the Ethiopian Strategy Support Program reveals mechanised farming can significantly reduce labour work. According to the study, wheat farmers in the Southeastern part had 55pc less labour output than other farmers using traditional methods to prepare and plough their land.

Experts observe that despite the availability of a 38.5 million ht arable land area which accounts for 34pc of the total landmass, issues related to incompatibility and quality of agricultural machinery are impeding the sector from producing surplus, attaining food security.

Gemeda Tsegaye, agricultural mechanization expert, believes the initiative to establish such a technical centre is overdue, considering the massive investment in mechanization.

"We can't increase production using a shovel," he said.

PUBLISHED ON

May 13,2023 [ VOL

24 , NO

1202]

Radar | Jun 15,2019

Radar | Jan 05,2019

Radar | Jan 09,2024

Fortune News | Oct 19,2019

Fortune News | Jun 10,2023

Covid-19 | Jan 30,2021

Radar | Apr 24,2021

Radar | Jun 26,2021

Fortune News | Jul 15,2023

Fortune News | Oct 30,2022

Dec 22 , 2024 . By TIZITA SHEWAFERAW

Charged with transforming colossal state-owned enterprises into modern and competitiv...

Aug 18 , 2024 . By AKSAH ITALO

Although predictable Yonas Zerihun's job in the ride-hailing service is not immune to...

Jul 28 , 2024 . By TIZITA SHEWAFERAW

Unhabitual, perhaps too many, Samuel Gebreyohannes, 38, used to occasionally enjoy a couple of beers at breakfast. However, he recently swit...

Jul 13 , 2024 . By AKSAH ITALO

Investors who rely on tractors, trucks, and field vehicles for commuting, transporting commodities, and f...

Jun 28 , 2025

Meseret Damtie, the assertive auditor general, has never been shy about naming names...

Jun 21 , 2025

A well-worn adage says, “Budget is not destiny, but it is direction.” Examining t...

Jun 14 , 2025

Yet again, the Horn of Africa is bracing for trouble. A region already frayed by wars...

Jun 7 , 2025

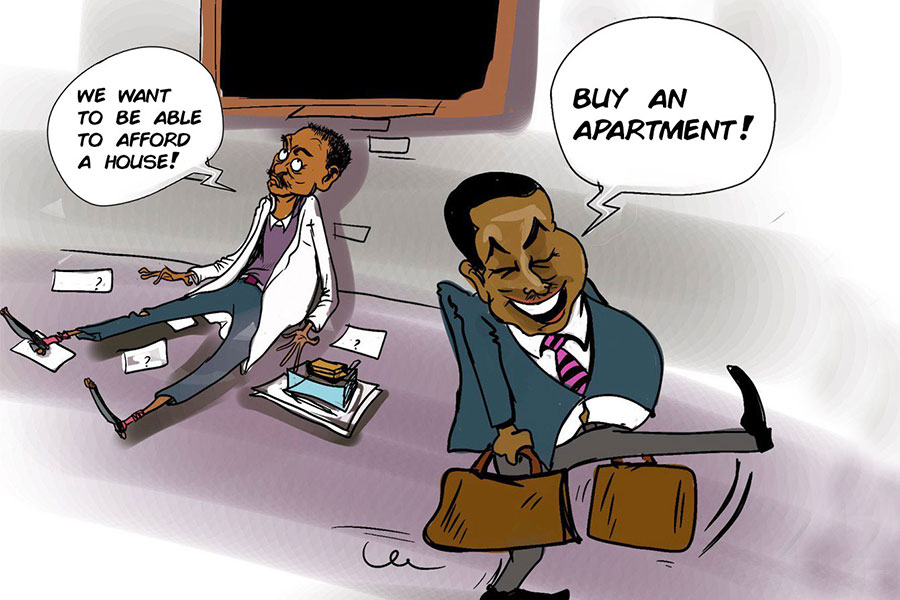

Few promises shine brighter in Addis Abeba than the pledge of a roof for every family...