Thousands of people may get support to establish businesses under the government's small and medium enterprises scheme. Evolving to the next phase is a daunting task, as the founders of YZS Leather Handcraft & Machine-Made Products Plc found out. Graduating from a small manufacturing enterprise five years ago brought a sense of pride to one of its founders, Yishak Mengistu. His enthusiasm was understandable. His company is among four percent of the 34,000 small manufacturing enterprises that had achieved the feat.

Yishak and his shareholders were determined to make their company, incorporated in 2002 with 6,000 Br in capital and two pieces of machinery, produce leather goods for export. YZS had surpassed the 1.5 million Br capital threshold for a medium-sized manufacturer. It would have been unattainable if not for the support in workspace, loans, training and market linkage facilitation courtesy of the Addis Abeba City Administration.

The company's capital grew to 10 million Br; it continued to make shoes, bags, wallets, mats and bedding, processing around 8,000 square feet of leather each year. It supplied products to the Ethiopian Tourist Trading Enterprise and souvenir shops across the city. At its peak, YSZ was generating over five million Birr in annual revenues while managing a workforce of close to 100.

Nonetheless, the long list of accomplishments is a thing of the past.

The COVID-19 pandemic, which had an unprecedented impact on global tourism, forced souvenir shops cut back on orders. The icky development pushed YZS to cut productivity to less than half of the 80pc it had been operating before the pandemic.

"As orders dropped, we cut our production," said Yishak.

Two years into the pandemic, YZS has yet to recover.

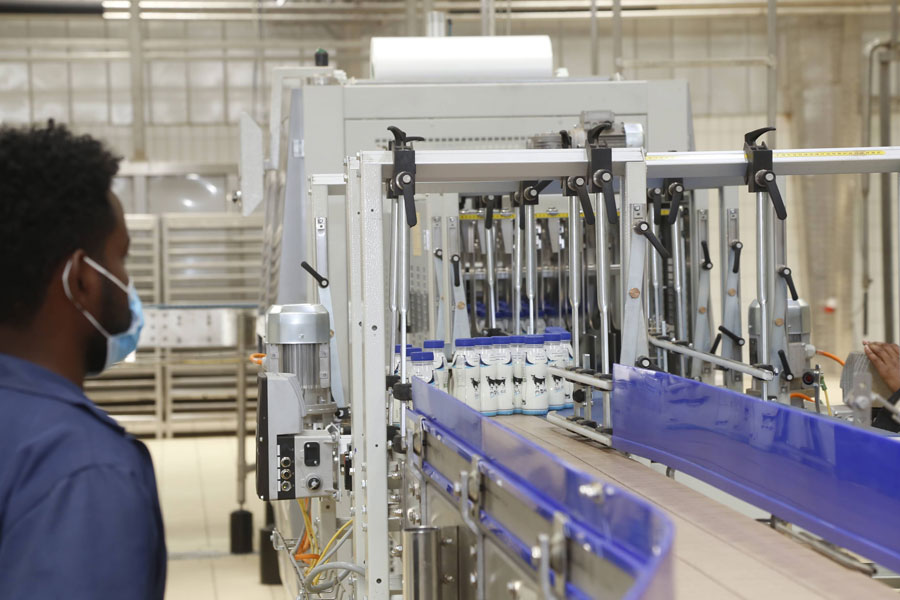

A few dozen workers were at the company's factory in the industrial sheds in the Saris area last week. They wore aprons at their workstations, cutting leather strips, fashioning zippers and stitching bags. Yishak was on his feet, coordinating the activities or what was left of them. Despite the setbacks, he still has hope for a turnaround.

“We won't stop," he told Fortune.

Yishak loves his job; he has fought to get it all back over the past two years. Retaining buyers has been an uphill battle for the determined co-founder as only 13 of the more than 50 buyers have stuck around.

YZS is a small company representing the tribulations of a bigger industry where industry leaders such as the Ethio-Leather Industry Plc (ELICO) suffer as much.

Privately owned for over 27 years, ELICO has been shipping the bulk of its products to markets in Italy, India, and China. It exports nearly two-thirds of its products, averaging 10 million dollars in annual revenues before the pandemic. Its managers have seen production and earnings decline sharply. They have already come to terms with earnings of no more than five million dollars this year. ELICO has made three million dollars in revenues over the past eight months.

A salesperson for Ker Ezhi Ethiopia, a leather manufacturer established in 2005, organises handcrafted leather purses on the counter of a store the company runs in the Kazanchis area.

“Demand has been falling for the last three years,” said Abebe Teklu, managing director at ELICO.

Leather manufacturers used no more than 39pc of capacity last year, while the figure stood closer to 25pc for several, a survey conducted by the Leather Industry Development Institute (LIDI) discovered.

Manufacturers like ELICO, a subsidiary of MIDROC Group, may have stayed by a thread. Many others have opted to leave the industry, unable to deal with challenges from the unavailability of quality hides and skins to the loss of export markets due to the global pandemic.

The reality is no less grim for one of the country's oldest manufacturing industries. No other company illustrates the leather industry's trials over the century as vividly as Tikur Abay Shoe Factory. Commercial leather production got its start nearly a century ago when the then Asko Tannery first opened its doors. An Italian businessman established the company in 1935 he named Darmar. Its ownership was transferred to different owners through the decades, first sold to an Armenian in 1942. It was nationalised in 1975 when the military-Marxist regime - the Dergue - restructured it into two enterprises, Anbessa Shoe Factory and Awash Tannery.

Following the downfall of the military regime, the company was re-established under the National Leather & Shoe Corporation. It was transferred back to private ownership in 2011 for 4.5 million dollars. Anbessa produces kids' shoes, bags and belts for the local and export markets, helping generate the 36 million dollars the country earned from the exports of leather products last year.

Four years before Anbessa Shoe Factory was privatised, government bigwigs labelled the leather industry as a priority sector for their industrial-led development policy.

In contrast to other labour-intensive manufacturing industries, leather processing is capital and scale intensive. The value chain comprises five segments from pastoralists and ranchers to slaughterhouses, manufacturers and retailers. In between are intermediaries like those who collect and trade raw skins and hides to tanneries, which process the inputs into semi-finished and finished leather and leather products.

Anbessa Shoe and ELICO are a few of the 29 tanneries, 21 footwear manufacturers, and 19 leather production firms that hired over 10,000 workers. The micro and small enterprises like YZS, around 400, run small workshops that mushroomed across the country.

However, the largest chunk of exports, followed by shoes, are shoe uppers, garments, upholstery, bags, industrial gloves and finished leather.

Despite the promise and the potential policymakers pinned their hopes, the past two years have been particularly disappointing. No less than 15 leather manufacturers have closed shops. The list is long but includes Hafede, Walya, Debre Birhan, Mersa, Sheba and Kombolcha tanneries. Their woeful absence from the market in supplying finished leather to international markets and local manufacturers directly bears the dismal export figures in the official statistics.

Exports from finished leather goods plunged 72pc last year from three years ago. Only eight finished leather manufacturers, including ELICO, accounted for 89pc of last year's export earnings, shipping 22.7 million dollars worth of leather products.

A report produced by the central bank attributed the fall in export volume and drop in international prices to declines by half in the earnings from leather and leather products. A kilogramme of leather products had received 20 dollars in the global market two years ago. This has dwindled to 15.9 dollars a kilo.

Volume in exports has seen an even more alarming drop. Pre-pandemic, around 6,200tn of leather products were shipped abroad annually. One-third of it made it to the international markets last year, leading the share of leather and leather products in total merchandise export to shrink to one percent from 2.4pc the previous year.

This is a painful loss to an industry that accounted for 7.2pc of all exports in the 16 years before 2016. Current performance is a far cry from what the government plans to generate 130 million dollars from exporting leather products this year. Earnings over the first three quarters did not top 40 million dollars.

Operating at less than half capacity, exports to places like Italy and Germany provided manufacturers a much-needed lifeline. Yet, the trials were not over. The United States' decision to delist Ethiopia from the African Growth & Opportunity Act (AGOA) late last year and the revocation of duty-free privileges it entailed landed a crushing blow to manufacturers and exporters. Leather products constituted a significant share of the 6,500 items Ethiopia exported to the US market, benefiting from the quota and duty-free regime. The Biden Administration's decision has unsettling ramifications for the leather industry and textile manufacturers such as New Wing Addis Shoe Factory.

Incorporated in 2011 with 3.7 million Br capital, it supplies women's leather shoes to five Americal buyers. All but one of them have stopped sourcing products from New Wing Addis. The Missouri based Wolff Shoe continued as a loyal customer, albeit with the 10pc import tax levied by the US government. Managers of New Wing Addis may have found new buyers in Hong Kong and Japan to keep doors open and the machines running. Yet, they say the new destinations are not as lucrative as the US had been. The company exports a pair of shoes for two dollars on average.

“We're selling shoes at a low price,” Evano Mesfin, deputy general manager of New Wing Addis, told Fortune. “We don’t make a profit unless we produce and export in bulk.”

Others like Anbessa Shoe are trying to find buyers in African markets such as Madagascar, Kenya, Somalia, and South Sudan. Beamlak Nigussie, general manager of the company, has yet to see the results "satisfactory.”

Ethiopia's loss of market in the United States through AGOA runs deep. The US government's scheme to African countries in the mid-1990s made Ethiopia one of the leading garment exporters to the United States from sub-Saharan countries. In 2020, half of the 525 million dollars worth of goods shipped to the US were under AGOA. Clothing and leather footwear accounted for a significant share of the shipments.

Western firms such as Pittards and Chinese manufacturers like the Huajian Group were attracted to open leather manufacturing plants primarily due to AGOA.

Huajian came to Ethiopia in 2011. It was the top exporter three years ago, exporting 15.8 million dollars worth of leather products. Since last year, the company has been conspicuously absent from the exporters' list.

“The company did not shut down its factory,” said a communications officer at LIDI, speaking anonymously.

A visit to Huajian's factory in the Lebu area tells a different story. A few weeks ago, the premises was dead silent, with no activities visible, bar the quietly strolling security personnel and the squawking of birds flying overhead. The security personnel blocked access to reporters but described the uneventful scenes at the factory for around two years. The communications officer at the Institute claimed the inactivity was due to the company's laying off of some of its workers.

“It's only a temporary setback," said the officer.

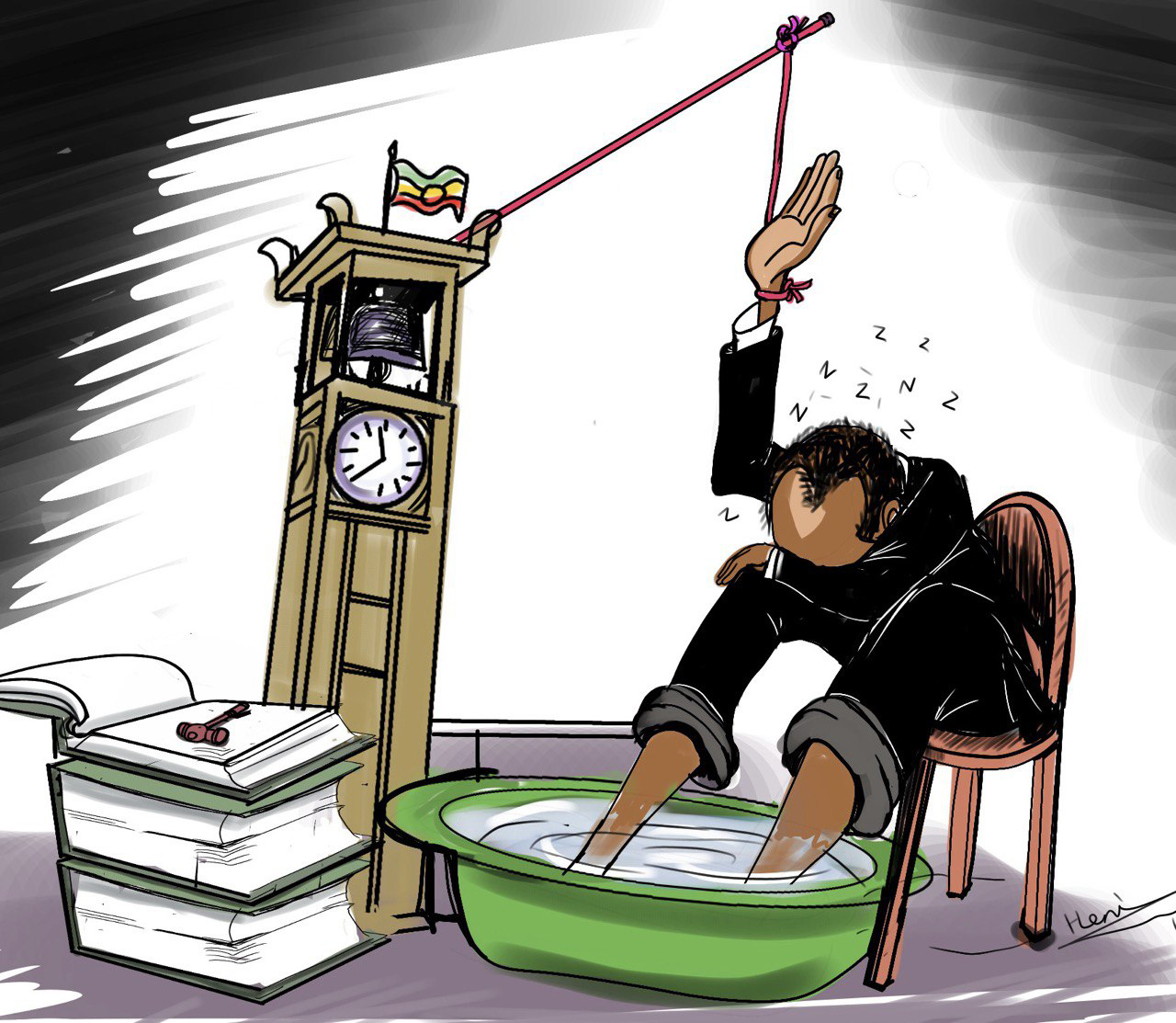

Setbacks, however, demand urgent policy responses, experts advise. Ermias Wodajo, a private consultant, is one of these experts urging the authorities to make policy changes to respond to falling demands in the international market.

“Manufacturers required to export should be allowed to sell their products domestically," he said.

Leather manufacturers' woes do not stop there. They have to contend with the imports of leather products as well. Their association had appealed two years ago for the authorities to impose higher tariffs on imported leather goods. Comprising 120 members, the Ethiopian Leather Manufacturers Association has leaders who see higher tariffs shelter the industry from disappointing export results, allowing them to sell products in the domestic market for higher prices.

Yishak of YSZ believes in putting a tariff break, the authorities can stop the "flooding" of imported leather products making local manufacturers compete against companies overseas that sell Ethiopia 19 million dollars worth of footwear annually.

To the dismay of the association leaders and businesspeople like Yishak, leather products were skipped when federal authorities adjusted the excise tax on more than 50 imported items two years ago.

Mohamed Hussein, deputy director-general of the Institute, contends not all manufacturers have market problems as much as they do battle with shortages of materials input.

The industry is heavily reliant on livestock resources. Though Ethiopia claims to have the largest cattle population at nearly 60 million heads, the leather industry is plagued by a lack of quality skins and hides. Tanneries could not source undamaged raw materials from the hide collectors and traders.

The industry sources over 60pc of its raw materials locally, but manufacturers need over 20 varieties of chemicals to process the skins. Over the first half of this year, less than eight million kilos of processing chemicals were shipped in. The volume is nowhere near the 15 million kilos (estimated to cost around 30 million dollars) needed, according to industry players. The overbearing issue of foreign currency shortages is a burden on leather manufacturers, too.

As if the problems were not enough, Yishak faces yet another predicament.

The city administration recently notified his company to vacate the shed his company has been using for five years. The city officials argue the premise is designated for small manufacturing enterprises that have yet to graduate to the medium category. Yishak's company is a victim of its own success but not thriving enough to make the transition during the most challenging times.

“I don't think we can afford to move out," said Yishak.

PUBLISHED ON

Apr 09,2022 [ VOL

23 , NO

1145]

Viewpoints | Mar 18,2023

My Opinion | Nov 19,2022

Featured | May 08,2021

Fortune News | Jun 19,2021

Commentaries | Jan 26,2019

Fortune News | Dec 29,2018

Fortune News | Apr 30,2022

Radar | Jan 31,2021

Radar | Aug 13,2022

Viewpoints | Nov 11,2023

Dec 22 , 2024 . By TIZITA SHEWAFERAW

Charged with transforming colossal state-owned enterprises into modern and competitiv...

Aug 18 , 2024 . By AKSAH ITALO

Although predictable Yonas Zerihun's job in the ride-hailing service is not immune to...

Jul 28 , 2024 . By TIZITA SHEWAFERAW

Unhabitual, perhaps too many, Samuel Gebreyohannes, 38, used to occasionally enjoy a couple of beers at breakfast. However, he recently swit...

Jul 13 , 2024 . By AKSAH ITALO

Investors who rely on tractors, trucks, and field vehicles for commuting, transporting commodities, and f...

Jul 12 , 2025

Political leaders and their policy advisors often promise great leaps forward, yet th...

Jul 5 , 2025

Six years ago, Ethiopia was the darling of international liberal commentators. A year...

Jun 28 , 2025

Meseret Damtie, the assertive auditor general, has never been shy about naming names...

Jun 21 , 2025

A well-worn adage says, “Budget is not destiny, but it is direction.” Examining t...