Steel factories will not be allowed to produce while operating below capacity without sufficient justification, says the Ministry of Mines & Energy.

The Ministry is working on a draft directive for the factories to report their production capacities every quarter within 10 days of halting production. The directive allows the government to revoke a factory's licence, provided its requirements remain unmet.

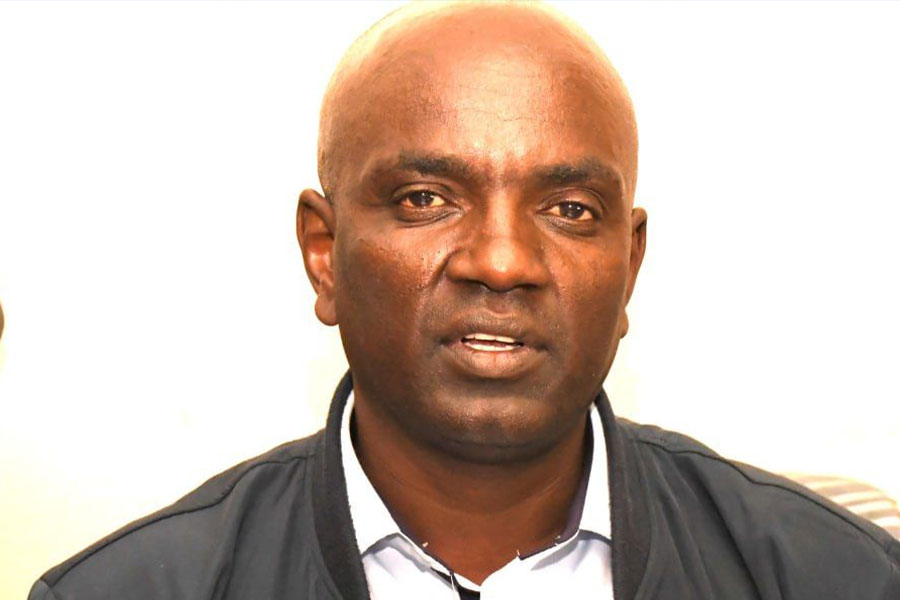

According to the State Minister for Mines & Energy, Million Matewos, the directive is prepared to ease the input shortage by enhancing the productivity of domestic producers. The Ministry says it wants to identify plants with capacity and support underperforming factories in their operation.

For Takele Uma, minister for Mines & Energy, the move is "more supportive" than meant to exercise control.

Following the green lights from the Council of Ministers, experts at the Ministry have been preparing regulations and directives for different minerals such as ceramics and granite since last year.

A lobby group formed in 2008, the Ethiopian Association of Basic Metal & Engineering Industries, representing 75 steel and metal manufacturers, has been lodging complaints to officials about foreign currency and raw material shortages. The metal industry needs raw materials, close to 12 million tonnes, to perform at full capacity. Most factories struggle to survive even after they collect scrap metals from federal agencies - they operate at less than 10pc capacity.

The Association is unaware of the draft document and attributes supply shortages as a root cause. According to its leader, Solomon Mulegeta, manufacturers have been pleading for a lower price of scarps.

In july this year, authorities designed a short-term plan to end scrap metal auctions and offered discount prices to alleviate the scarcity of raw materials. Three months later, six factories were identified and received 10,000tns scrap allocated based on their capacity.

One of them, Dire Steel Plc used to ship billets from China, Turkey, and India to produce rebar and wires and got the last approval for a letter of credit (LC) a year ago. Established a decade ago with a capital of 400 million Br (grew to 1.2 billion Br), the company used scrap metal from Dire Dewa University, which its managers claim was insufficient.

With an annual production capacity of 360,000tns, it has been six months since Dire Steel ran out of raw materials and stopped production. According to its executives, the production capacity is declining due to poor quality scraps compared to imported billets. The company was offered scrap metals. However, its managers did not take the 82tns of scarp from Dire Dewa University.

According to Sewnet Abeje, the company's CEO advisor, transportation costs have been another headache.

State Minister Million said they got approval from the Ministry of Finance to subsidise transportation and fuel costs.

Steel factories require foreign currency to import the locally unavailable billet metal, attributing it to their low production output.

Inputs for cement factories such as limestone, pumice, gypsum, and basalt are available domestically, entering into a contract with youth associations granted concessions by the government. The cement plants only require access to foreign currency to import coal, said Sewenet.

According to Dereje Gebreselassie, CEO of Tadash Steel Manufacturing Plc, a metal factory in Dukem town, a temporary market fluctuation of the price of steel is mainly linked with the rising cost of raw materials. Dereje appreciates the Ministry's attempts but is still worried about future shortages.

"There is no option to source from the domestic market if we can't get the quantity we need," said Dereje.

However, the Ministry's officials disagree with the assessment claiming that the scarp accumulated in federal institutions would be enough for the next two years.

Getasew Ashagire (PhD), assistant professor of sustainable manufacturing at Addis Abeba University, said that scraps in various federal institutions are not in good condition, full of rust and unavailable in the quantity demanded by metal manufacturers. He observed metal industries worldwide are going through similar challenges. Although recycling metal material takes 75pc less energy than mining raw materials, it may also result in low-quality metal products that would take a toll on the infrastructure which uses it and damage contractors' reputations, warned the expert.

According to Ministry officials, the draft directive will be tabled for discussion and debate before being enforced next year.

Getasew urged officials to take a lesson from international manufacturers shutting down their factories for the shortage of raw materials and high energy costs. Dire Steel continued to pay salaries for nearly 300 employees while temporarily ceasing its operations.

"Scraps are a short-term solution but cannot curb the challenges in the long run," said the expert.

The Ministry has floated a public tender to hire a consultant to develop a feasibility study to invest in the iron-ore industry.

Construcion rebars ready for transport at local steel factory.

PUBLISHED ON

Dec 10,2022 [ VOL

23 , NO

1180]

Fortune News | Aug 27,2022

Radar | Jan 14,2023

Fortune News | Jun 11,2022

Radar | Aug 22,2020

Radar | Jun 21,2025

Dec 22 , 2024 . By TIZITA SHEWAFERAW

Charged with transforming colossal state-owned enterprises into modern and competitiv...

Aug 18 , 2024 . By AKSAH ITALO

Although predictable Yonas Zerihun's job in the ride-hailing service is not immune to...

Jul 28 , 2024 . By TIZITA SHEWAFERAW

Unhabitual, perhaps too many, Samuel Gebreyohannes, 38, used to occasionally enjoy a couple of beers at breakfast. However, he recently swit...

Jul 13 , 2024 . By AKSAH ITALO

Investors who rely on tractors, trucks, and field vehicles for commuting, transporting commodities, and f...

Oct 18 , 2025

The political establishment, notably the ruling party and its top brass, has become p...

Oct 11 , 2025

Ladislas Farago, a roving Associated Press (AP) correspondent, arrived in Ethiopia in...

Oct 4 , 2025

Eyob Tekalegn (PhD) had been in the Governor's chair for only weeks when, on Septembe...

Sep 27 , 2025

Four years into an experiment with “shock therapy” in education, the national moo...