Fortune News | Feb 23,2019

Ethiopia is exploring a draft regulation that would introduce recycled plastic (PET) into food and beverage packaging. Officials believe this move will reduce reliance on expensive imports and combat plastic pollution, but concerns linger about safety and feasibility. Plastic waste poses a significant environmental threat. By promoting recycling, officials hope to reduce the country's dependence on PET imports, curb plastic pollution, and potentially save foreign currency.

The Food & Beverage Industry Research & Development Center, spearheading the initiative. Bekele Mekuria, head of the Center, is urging bottled water, edible oil, and soft drink manufacturers to explore recycling options. Currently, PET imports cost Ethiopia 40 million dollars annually, placing a strain on foreign currency reserves. Bekele points to a successful policy shift last year, where prohibiting foreign currency allocation for blue dye import saved 15 million dollars. While a complete ban on PET imports is not imminent due to industry reliance, Bekele anticipates a gradual phase-out.

"Regulation is crucial due to the hazardous nature of chemicals involved," he told Fortune.

The standard was developed through a collaborative effort involving 10 organisations, including the Ethiopian Plastic & Rubber Association, the Ethiopian National Accreditation Service (ENAS), and the Ethiopian Food & Drug Authority (EFDA), for one and a half years, currently under review at the Ministry of Justice.

When all manufacturers work at full capacity, the country can produce nearly four billion pieces of plastic bottled water annually, raising concerns about plastic waste. The draft calls for manufacturers to invest in recycling infrastructure and waste collection systems. While the initial investment might be significant, long-term cost savings from reduced reliance on PET imports and potential brand reputation benefits associated with sustainability could outweigh the upfront costs.

However, it faces several hurdles.

With a growing focus on establishing quality standards and ensuring transparency in the process, recycled PET could offer a more sustainable solution for Ethiopia's bottled water industry, reducing dependence on virgin plastic and its environmental impact. However, industry players like Arki Natural Mineral Water, are sceptical about the quality and safety, citing inadequate chemical cleaning practices.

Dagmawi Getachew, manager at Arki Natural Mineral Water plant, expresses hesitation in compliance, recalling that their current practices involve virgin plastic because of limitations in the country's chemical cleaning processes for reused materials.

Under the SBG business group, the Arki water plant, established with 64 million Br capital, plans to continue importing PET from Saudi Arabia and India whether or not the regulation receives approval.

"Decreasing heavy tax levies will incentivise manufacturing better," Dagamawi said.

The draft regulation requires an Ethiopian Food & Drug Administration (EFDA) certificate of competence and license for businesses involved in the transport, storage, and processing of PET recyclables intended for food contact.

Belete Serahbizu (PhD), a material engineering lecturer at Adama Science Technology University, feels insufficient studies have been conducted to determine how recycled PET products may impact human health, particularly regarding the potential effects on the chemical structure of the material after processing.

"Detailed research is crucial to ensure the safety," he said.

Officials at the Ethiopian Food & Drug Administration (EFDA) concur. Mulat Tesfa, head of inspection and legal enforcement at EFDA underscore the importance of thorough preparations before implementing the regulation. He emphasises the need for rigorous laboratory testing procedures to ensure the safety of recycled plastic packaging for food and water products, acknowledging the potential environmental benefits.

The need for a united front to address concerns and ensure the success of the initiative is lauded by stakeholders.

Samson Ketema, general manager of the Ethiopian Plastic & Rubber Manufacturing Association, acknowledges that using recycled plastic for food packaging is not yet common practice in many countries. However, he views the regulations around PET recycling as a necessary step for future development.

"Standardising the recycling process is essential to ensure quality and safety," he said.

PETCO Ethiopia works collaboratively with the plastic industry to promote self-regulation in post-consumer PET recycling and participated in drafting the regulation. Mihret Teklemariam, the executive director, acknowledges the need for extensive discussions before implementing a system heavily influenced by European practices. She raises concerns about potential health risks and the significant financial investment required for plastic recycling plants.

Despite the current limitations, some manufacturers believe there could be potential for developing smaller-scale or more localised recycling initiatives in the future, gradually laying the groundwork for a robust recycling industry.

Getahun Gezahegn, general manager of Shemaya Plastic Manufacturing Plc, reflects on the increasing difficulty in securing foreign exchange. This shortage disrupts their operations, as the company relies on 40tns of PET annually. Even with imported machinery, Gezahegn doubts the viability of large-scale domestic recycling plants due to the high capital intensity of the industry and the additional inputs required that Ethiopia might not readily produce.

"Establishing a full-fledged recycling sector might require exploring alternative approaches beyond large-scale plants," he said.

The potential shift towards recycled PET packaging hinges on finding a balance between environmental goals, economic feasibility, and public health concerns. Experts emphasise the need for further research, investment in recycling infrastructure, and robust safety protocols for a successful implementation.

Ethiopia's Environment Protection Authority (EPA) reported recycling 57tns of plastic within six months. Yewubdar Alemu, an environment protection lead executive, stresses the urgency of addressing plastic pollution.

As plastic takes up to 500 years to decompose and can harm the environment through soil contamination, air pollution, and damage to crops, Yewbdar believes the new regulation will significantly decrease waste. Potentially Yewubdar hopes alternative packaging materials like glass or cartons will be explored and public awareness campaigns will promote plastic use reduction and proper waste disposal practices.

PUBLISHED ON

Mar 30,2024 [ VOL

24 , NO

1248]

Fortune News | Feb 23,2019

Fortune News | Mar 26,2022

News Analysis | Dec 08,2024

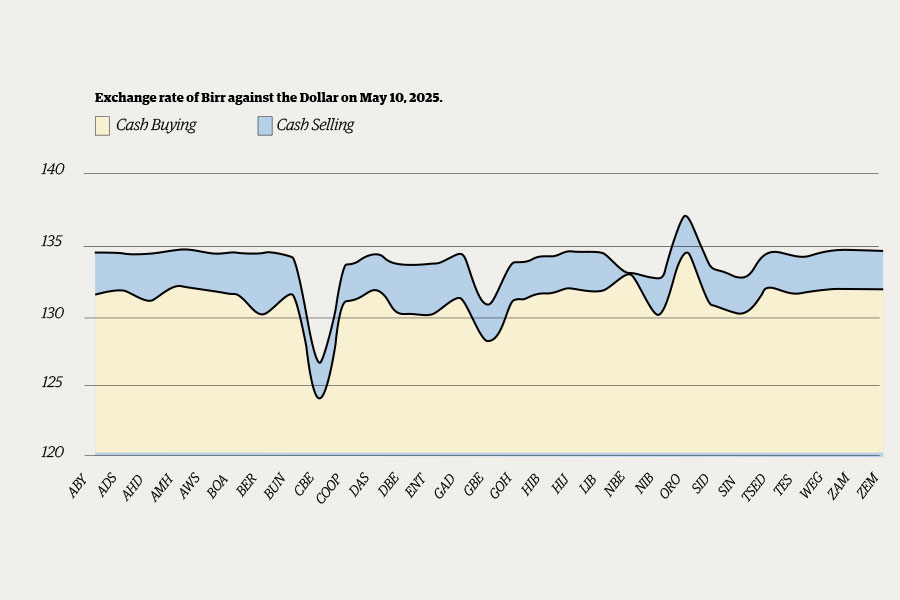

Money Market Watch | May 24,2025

Fortune News | Dec 14,2019

Fortune News | Jun 23,2019

Viewpoints | Dec 28,2019

In-Picture | Jun 08,2025

Radar | Mar 26,2022

Dec 22 , 2024 . By TIZITA SHEWAFERAW

Charged with transforming colossal state-owned enterprises into modern and competitiv...

Aug 18 , 2024 . By AKSAH ITALO

Although predictable Yonas Zerihun's job in the ride-hailing service is not immune to...

Jul 28 , 2024 . By TIZITA SHEWAFERAW

Unhabitual, perhaps too many, Samuel Gebreyohannes, 38, used to occasionally enjoy a couple of beers at breakfast. However, he recently swit...

Jul 13 , 2024 . By AKSAH ITALO

Investors who rely on tractors, trucks, and field vehicles for commuting, transporting commodities, and f...

Jun 28 , 2025

Meseret Damtie, the assertive auditor general, has never been shy about naming names...

Jun 21 , 2025

A well-worn adage says, “Budget is not destiny, but it is direction.” Examining t...

Jun 14 , 2025

Yet again, the Horn of Africa is bracing for trouble. A region already frayed by wars...

Jun 7 , 2025

Few promises shine brighter in Addis Abeba than the pledge of a roof for every family...