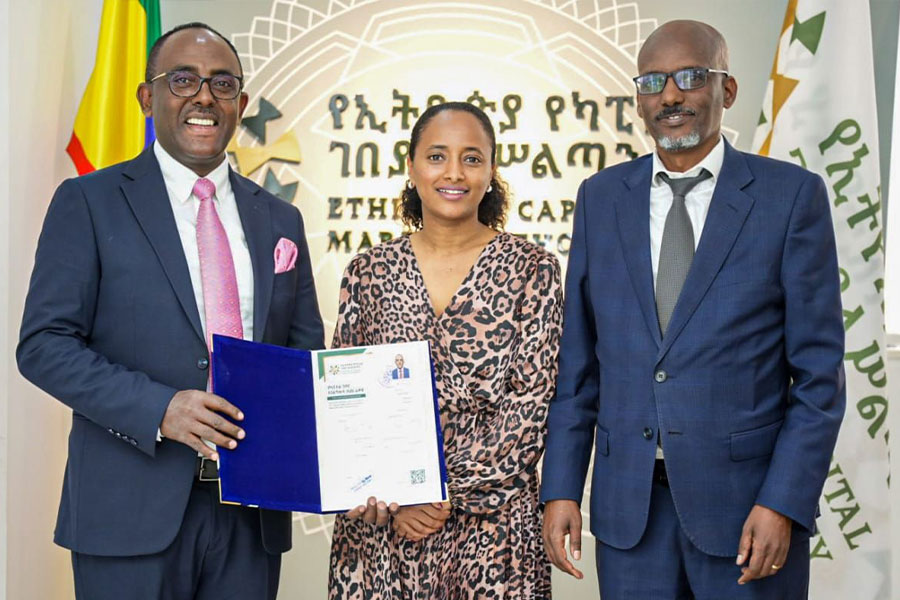

Haile Gebrselassie (left), an Olympic medalist and businessman, was excited to host Yinager Dessie (PhD) (centre), governor of the National Bank of Ethiopia (NBE), Melaku Alebel (centre-right), minister of Industry, and Eyob Tekalign (PhD), state minister for Finance, to launch an expansion of Marathon Motors Engineering’s assembly plant for Hyundai vehicles. Marathon, partly owned by Haile, added an assembly line and opened the country's first electric vehicle charging station.

“Our vision of decarbonisation of the transport and logistics sector is within reach,” declared Dagmawit Moges, minister Transport, who attended the launching ceremony.

The sole importer and assembler of the South Korean brand, Marathon opened the charging stations to integrate with the electric vehicles it offers in the Ethiopian market. The company’s value proposition? Electric is not a luxury alternative to fuel-guzzling cars, including the SUVs it sells, but an economic imperative. It will set drivers back a little over two Birr for a kilowatt-hour of electricity to charge their cars at the station. Once fully charged, the model Marathon assembles can travel 300Km. Around 30,000 Br spent at the charging station equates to an averge distance of 120,000Km, while major gas guzzlers can cost 13 times as much based on benzene retail prices.

This is welcome news for a government finding it hard to cope with fuel subsidies, which it plans to phase out eventually. Recently, it adjusted the retail prices of benzene and gasoline to their highest-ever levels (without adjusting for the depreciation of the Birr to a basket of major currencies). It has also incentivised the import and assembly of fuel-efficient vehicles by lowering import duties. But electric vehicles are far from replacing their environmentally unfriendly counterparts. They share 10pc of the global market, while they are virtually non-existent in Ethiopia. Tesla models, the leading electric vehicle brand, are a rare sight on the streets of Addis Abeba.

Marathon, which plans to expand into electric bus assembly, admits that the ride ahead will not be without snags. Over the past three years, despite its annual capacity to assemble 10,000 vehicles, severe foreign currency shortages did not allow its plant to put more than 1,500 cars out into the market. The company's executives also emphasised, during the launching ceremony, the need for removing duties for charging station inputs and car batteries.

PUBLISHED ON

Jan 01,2022 [ VOL

22 , NO

1131]

Dec 22 , 2024 . By TIZITA SHEWAFERAW

Charged with transforming colossal state-owned enterprises into modern and competitiv...

Aug 18 , 2024 . By AKSAH ITALO

Although predictable Yonas Zerihun's job in the ride-hailing service is not immune to...

Jul 28 , 2024 . By TIZITA SHEWAFERAW

Unhabitual, perhaps too many, Samuel Gebreyohannes, 38, used to occasionally enjoy a couple of beers at breakfast. However, he recently swit...

Jul 13 , 2024 . By AKSAH ITALO

Investors who rely on tractors, trucks, and field vehicles for commuting, transporting commodities, and f...

Nov 1 , 2025

The National Bank of Ethiopia (NBE) issued a statement two weeks ago that appeared to...

Oct 25 , 2025

The regulatory machinery is on overdrive. In only two years, no fewer than 35 new pro...

Oct 18 , 2025

The political establishment, notably the ruling party and its top brass, has become p...

Oct 11 , 2025

Ladislas Farago, a roving Associated Press (AP) correspondent, arrived in Ethiopia in...