Fortune News | Sep 08,2019

Feb 8 , 2020

By TEMESGEN MULUGETA ( FORTUNE STAFF WRITER )

A local automotive importer has ventured into a new industry by setting up a mango juice processing and water bottling business with an investment of 150 million Br.

Sendelet Food Processing, a subsidiary of Risiq Group, set up a juice and water bottling plant in Burayu, Taxeq Industry Zone, West Shoa, Oromia Regional State. The plant is expected to start production in the middle of this month. The juice will be branded Omango, while the water will bear the brand name Owater. Both products are expected to hit the market this March.

Risiq Construction, a subsidiary of the family-owned Risiq Group that was established in 2010 and mainly engages in the food and beverage, automotive dealership, import-export and construction businesses, constructed the 1,000Sqm plant. It imported the Sheen Star juice processing machines from China.

The new plant, which took one and a half years to complete, has the capacity to process 50,000 bottles of juice a day in half-litre and 300ml bottles. The water bottling line can bottle 300 jugs of water an hour, each with a capacity of 20lt.

Sendelet imports the raw mango pulp, the inner fleshy yellow or sweet part of the mango, from India to produce the juice. For the water bottling plant, the company gets the water from the underground burrow located inside the compound.

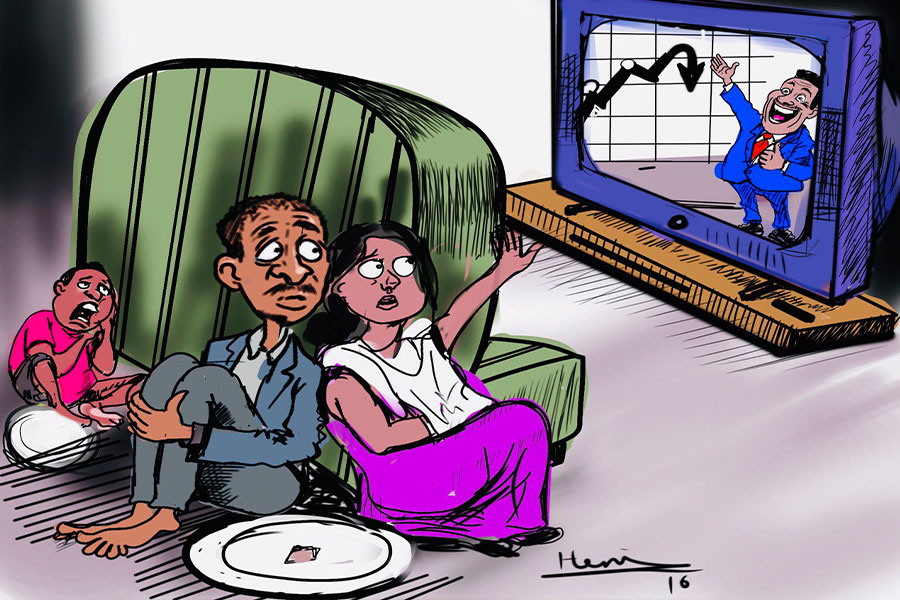

Owater and Omango will join the burgeoning water bottling and juice processing business in the country, which has 87 water and seven juice processing plants. The 87 water bottlers supply just five percent of national consumption, while the nation has a population above 100 million.

Currently, the management of the company is recruiting new employees and targets to have 40 employees for the first year.

"We'll expand the number of employees to 80 when we start working in double shifts," said Nesrdin Redwan, manager of the plant, who adds that the plant expects to process guava and multi-fruit juice with carton packaging after undergoing an expansion.

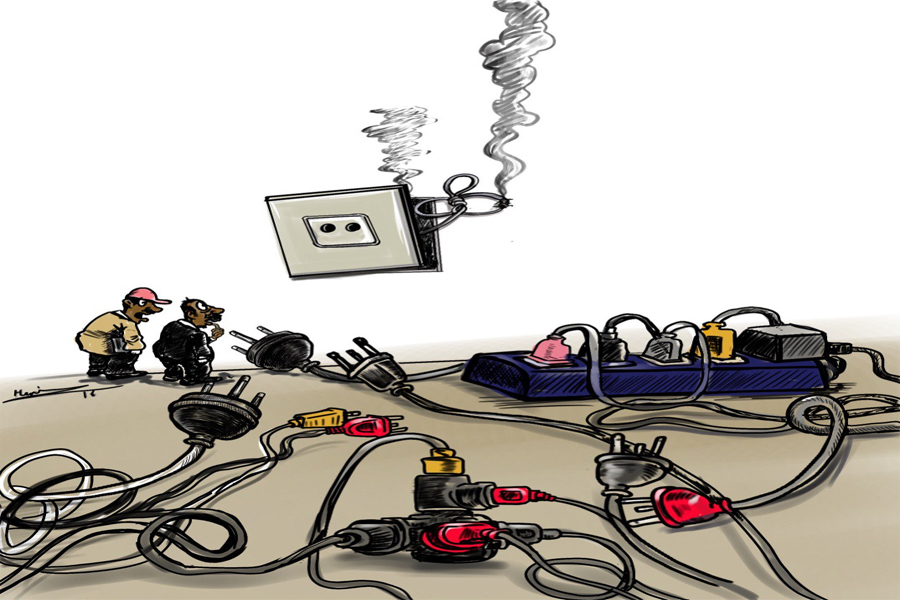

Electric power outages and political unrest in the area were the main challenge that the owners of the company faced during the construction of the plant, according to Nesrdin.

Sendelet Food Processing, which was established in 2014, has already been making and supplying PET lightweight plastic to water bottlers and juice processors in Ethiopia. The company mainly targets the local market.

"We also have a plan to export our products to neighbouring countries, including Djibouti and Sudan," said Nesrdin.

Hailemariam Kebede (PhD), a lecturer at Addis Abeba University's School of Commerce, recommends the management of the company consider decreasing the price of the product at least for six months to penetrate the market.

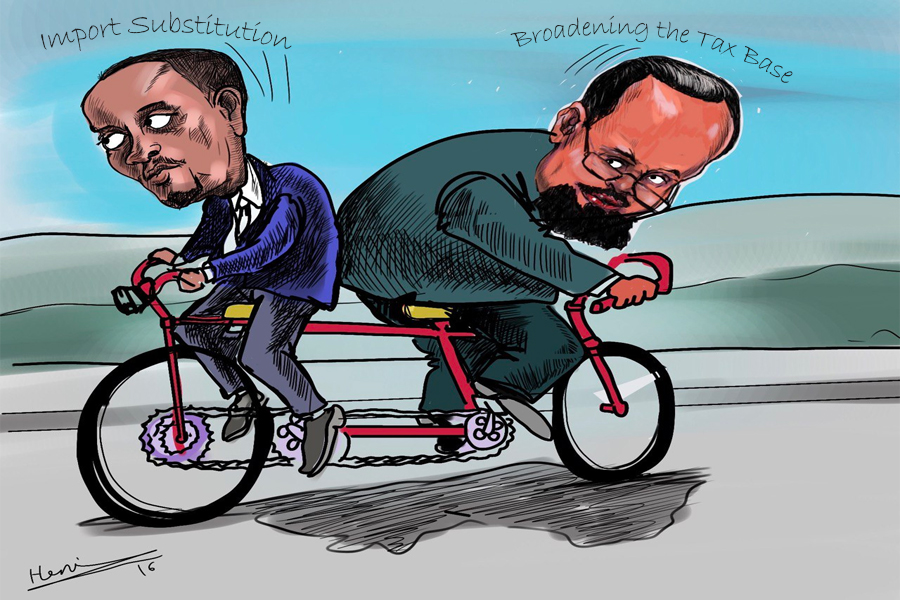

Hailemariam also says that the company should produce the raw material locally to save foreign currency.

"If they didn't manufacture the raw material locally," said Hailemariam, "it would be good to make a joint venture agreement with another company."

PUBLISHED ON

Feb 08,2020 [ VOL

20 , NO

1032]

Fortune News | Sep 08,2019

Covid-19 | May 09,2020

Radar | Apr 22,2022

Fortune News | Apr 26,2019

Radar | Sep 06,2020

Radar | Mar 27,2021

Radar | Jun 07,2020

Featured | Nov 02,2019

Radar | Sep 18,2021

Fortune News | Jul 18,2021

Jul 13 , 2024 . By AKSAH ITALO

Investors who rely on tractors, trucks, and field vehicles for commuting, transportin...

Jul 13 , 2024 . By MUNIR SHEMSU

The cracks in Ethiopia's higher education system were laid bare during a synthesis re...

Jul 13 , 2024 . By AKSAH ITALO

Construction authorities have unveiled a price adjustment implementation manual for s...

Jul 13 , 2024

The banking industry is experiencing a transformative period under the oversight of N...

Jul 20 , 2024

In a volatile economic environment, sudden policy reversals leave businesses reeling...

Jul 13 , 2024

Policymakers are walking a tightrope, struggling to generate growth and create millio...

Jul 7 , 2024

The federal budget has crossed a symbolic threshold, approaching the one trillion Bir...

Jun 29 , 2024

In a spirited bid for autonomy, the National Bank of Ethiopia (NBE), under its younge...