Viewpoints | Oct 20,2024

The roads leading to Megenagna were crowded and hectic as ever. Street vendors selling a flurry of consumer goods such as clothes and shoes were an inconvenience for the innumerable pedestrians attempting to circumvent the busy streets to reach where they needed to go. Among the crowd were shoppers. Some stopped to peruse the goods the street vendors had on offer; others were looking to buy something at one of the busy shopping malls at the heart of Megenagna.

The shopping centres in the area are a hotspot for electronics retail. Televisions, washing machines, tablets, and smartphones are some of the goods on offer. A few people were looking to buy a smartphone as Alexander Haileselassie roamed from one shop to another last week. He was searching for the cheapest smartphone money could buy.

The first store he visited was owned and run by Almaz Gebru, who sat in her four-square-metre stall surrounded by phones and accessories. Her stall lies on the first floor of the Marathon Motors building, adjacent to the Diaspora Roundabout in the Yeka District. It is home to dozens of similar shops.

In the past, Almaz’s stock would have been hogged by phones manufactured by Samsung, the South Korean giant. It is no longer the case. Many of the devices on display are products of Redmi, a subsidiary of Xiaomi, the Chinese electronics company.

Prices have changed, too. They have become more expensive.

Almaz sold a Samsung Galaxy Note 9 smartphone for 14,000 Br a few months ago. She asked buyers for no less than 21,000 Br last week. It was beyond what Alexander, a St. Mary’s University student, could afford. The drastic price rise is not the only barrier for consumers like Alexander. A lack of options is also an issue. Some retailers had Samsung smartphones manufactured nearly a decade ago on display.

“We stopped buying in bulk,” said Almaz. “Wholesalers are out of stock, too.”

The main supply sources for wholesalers were travellers bringing personal items duty-free in their luggage. Smartphones are prime goods, light and convenient to carry and attractive for their margins. However, this lucrative business dried up after authorities suspended the duty privileges last December, leaving mobile retailers in despair.

Within half an hour of his arrival, Alexander had turned down offers from three mobile retailers. Unable to make up his mind, he began walking along Kenenisa Avenue. Not too far a big mobile phone retail store decorated with bright lights caught his eye. It is run by Tecno Ethiopia, a domestic mobile phone assembler.

Alexander was the day’s first customer for two saleswomen sitting behind a counter. Despite the shop’s large size, very few devices were on display. What little was on show carried price tags ranging between 2,400 Br and 20,000 Br. Alexander decided to buy the Tecno Spark 8 Android smartphone with 10,000 Br. To his surprise, the saleswoman told him the phone he had chosen was not assembled locally.

“The phone is manufactured in China,” Hana Mamo, a saleswoman, told Alexander.

She said all the models displayed in the shop were imported from China.

“It’s been a few months since we had locally-assembled phones in stock,” she said.

Mobile Phone Stories in Addis Abeba.

Tecno has a considerable presence in the Megenagna area, with at least four outlets closer to each other.

Incorporated in 2011, the China-based company launched operations in Ethiopia with a capital investment of more than one million dollars. It can assemble a million tablets and smartphones a month.

Tecno is among the 18 local assemblers that joined the industry over the last decade, with an aggregate production capacity of nearly 24 million devices annually. Assemblers such as SMADL, Oking, Ken Xen Da, Hidase and Tana had been gaining momentum and a fair portion of the market share, dominated by imported brands.

Established seven years ago, SMADL Communications Terminal Factory Plc can manufacture up to 100,000 devices monthly. Hidase Mobile & TV Manufacturing Plc assembles feature phones that fit demand from rural markets.

Domestic assemblers saw products grow more diverse in prices, technology, and quality. The growth attracted buyers. And the companies have become more assertive and visible.

In 2016, Tecno was one of the bidders to supply the Central Statistics Service with 180,000 tablets estimated to cost over one billion Birr.

Domestic assemblers controlled nearly a third of the market share by 2017. They employed over 6,500 and paid over half a billion Birr in profit taxes to the federal government. Their export performance was comparable to other sub-sectors such as textile and leather, which received considerable government support. Six years ago, Ethiopia earned a record 44 million dollars from the export of electronics and cables. Compare this to export revenues from textile products, around 90 million dollars during the same period.

Assemblers like Tecno used to ship their products to other African markets, such as Nigeria and Rwanda.

However, the good days did not last.

A rampant contraband trade was among assemblers’ most pressing challenges and threatened their market share. Even when domestic assemblers were at their peak, devices imported through illicit channels accounted for over 60pc of the smartphone market. Electronics accounted for a third of smuggled goods valued at 4.3 billion Br seized by the authorities last year. The contraband practices were growing along with the spurt in mobile phone users. The number of telecom subscribers jumped by more than a quarter in five years, reaching 58.5 million.

Retail shelves in the Megenagna area once were crammed with smuggled mobile phones. Not anymore. Contraband trade slowed down due to instability along the main routes, such as from Moyale to Hawassa, according to a mobile phone retailer at Megenagna.

Officials credit thorough law enforcement operations to the slowdown in the illicit flow of mobile devices into the country.

Contraband trade is not the only issue bothering assemblers. The shortage of foreign currency has forced most of them to close their doors over the past three years. The remaining are hanging on by a thread. According to Abiy Minwuyelet, a group chairperson at Information & Communication Technology Association Ethiopia (ICT-ET), only two assemblers remain in operation.

The stores in Megenagna are a hub for electronics retail in the capital. Smartphones and related accessories are the most commonly stocked items but locally-assembled devices have all but disappeared from shelves.

“They are operating at less than 30pc capacity,” he told Fortune.

Established in 2010, the lobby group represents over 200 companies active in information, communications and broadcasting technologies.

Among the assemblers that have dialled it in is Cell Tell Trading & Manufacturing Plc, the assembler of G-TiDE mobile devices. Established in 2013, the company has the capacity to assemble 100,000 mobile phones using parts imported from China. It stopped production three months ago.

“The investment environment is not suitable for companies like ours,” said Yeshitla Kifle, managing director.

The assemblers depend on the import of semi-knocked-down (SKD) and completely-knocked-down (CKD) parts to put together their devices. Due to the forex crunch, they can no longer get their shipments in.

Incorporated in 2008 with an initial capital of 300,000 Br, Tana Communications Plc can assemble three million phones annually. It needs three million dollars annually to import component parts and operate at full capacity. Last year, Tana secured 250,000 dollars in foreign currency.

“We’re using less than five percent of our production capacity,” said Haymanot Ayalew, general manager.

The company imports 35 types of SKD parts to assemble a mobile phone unit. Two years ago, Tana made close to 26,000 devices.

The authorities are aware of the predicament the assemblers find themselves in.

According to Tsehaye Yenesu, head of the electronics manufacturing industries unit at the Ministry of Industry, almost all local mobile phone assemblers suspended operations four months ago. Along with the assemblers, dozens of cable and transformer manufacturers face a similar quandary.

Abinet Belay, an investment consultant with MPE Advisory Firm, argues the government should support local assemblers to generate their own foreign currency by exporting their products. Materials and parts imported by manufacturers and assemblers place second on the central bank’s forex allocation priority list. Inputs for edible oil production, medicine, pharmaceutical manufacturing, and laboratory reagents are a step ahead.

The Ministry, together with the Ethiopian Investment Commission (EIC), is attempting to attract foreign investors that can manufacture parts such as circuit boards and liquid crystal displays (LCD) locally, says Tsehaye.

“The problem can only be fixed by cutting assemblers’ forex requirements by manufacturing parts locally,” said Tsehaye.

Abinet argues it might not be realistic to expect the local manufacturing sector to make parts.

“Even if there is access to finance, the country lacks the know-how,” he said.

Haymanot from Tana says a lack of working capital also threatens assemblers’ survival.

“We’re barely receiving support from the government,” she said.

Local assemblers enjoy duty-free privileges while importing parts. They are also exempted from corporate tax for up to six years. Legislated town years ago, the excise tax law significantly reduced the tax burden imposed on manufacturers, excluding SKD and CKD parts from the list of items subject to excise tax.

Each year, the Ethiopian Investment Commission receives 4,300 applications asking for incentives. Over half were from the manufacturing sector, while the service and agriculture sectors followed. Almost two-thirds of the applications submitted were for the duty-free import of capital goods.

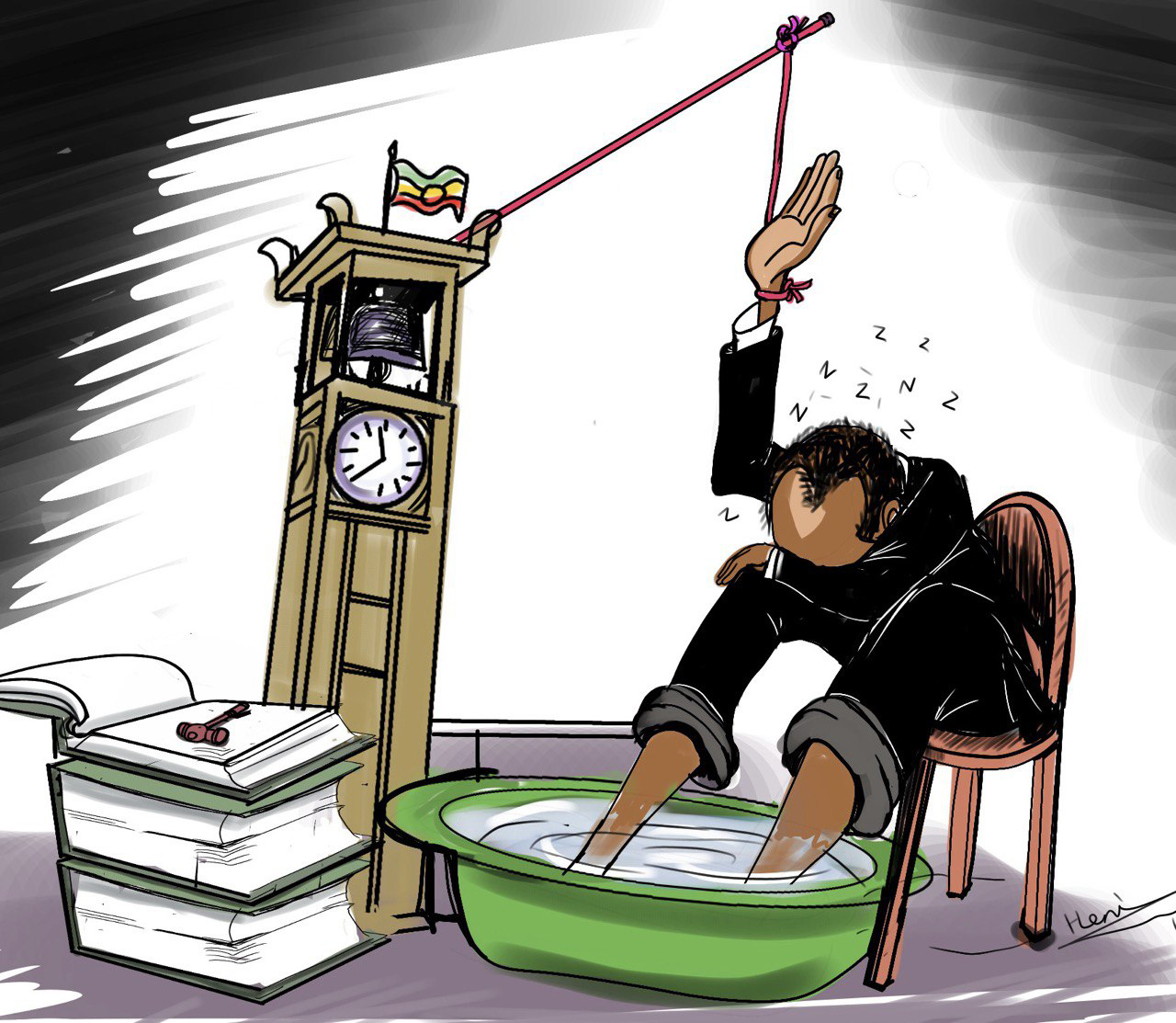

Nonetheless, officials are unhappy not seeing these incentives translated into productivity.

“Some foreign assemblers withdraw their operations after the incentive period ends,” said Tsehaye.

Most of the assemblers stayed for over a decade, nonetheless.

“We’ve been arguing the incentives should be performance-based,” said Abiy.

Assessments conducted by various government agencies concluded that the incentive packages were mismanaged and exposed to corruption and maladministration. One such evaluation by the Federal Ethics & Anti-Corruption Commission reveals that one-third of the duty-free privileges and tax exemptions granted to investors were open to corruption. Last month, the Ethiopian Customs Commission announced that it had suspended the illegal import of raw materials worth 530 million Br by investors.

Aschalew Tadesse, the Commission’s foreign direct investment (FDI) director, stresses that more conclusive research is necessary to determine where the problem lies. Experts at the Industry Ministry are studying to evaluate the effectiveness of the privileges offered to local assemblers.

“We’ll decide on the next step after completing the assessment,” said Tsehaye.

Users like Alexander will have to shell out exorbitant amounts to buy smartphones. Retailers like Almaz will have to make do with the products available on the market, however few and limited in their product diversity.

PUBLISHED ON

Aug 14,2022 [ VOL

23 , NO

1163]

Viewpoints | Oct 20,2024

Verbatim | Jan 07,2024

Verbatim | Aug 13,2022

Fortune News | Jun 10,2023

News Analysis | May 25,2024

Fortune News | Feb 17,2024

Fortune News | Jul 08,2023

Fortune News | Mar 30,2024

Fortune News | Aug 13,2022

Commentaries | Feb 18,2023

Dec 22 , 2024 . By TIZITA SHEWAFERAW

Charged with transforming colossal state-owned enterprises into modern and competitiv...

Aug 18 , 2024 . By AKSAH ITALO

Although predictable Yonas Zerihun's job in the ride-hailing service is not immune to...

Jul 28 , 2024 . By TIZITA SHEWAFERAW

Unhabitual, perhaps too many, Samuel Gebreyohannes, 38, used to occasionally enjoy a couple of beers at breakfast. However, he recently swit...

Jul 13 , 2024 . By AKSAH ITALO

Investors who rely on tractors, trucks, and field vehicles for commuting, transporting commodities, and f...

Jul 12 , 2025

Political leaders and their policy advisors often promise great leaps forward, yet th...

Jul 5 , 2025

Six years ago, Ethiopia was the darling of international liberal commentators. A year...

Jun 28 , 2025

Meseret Damtie, the assertive auditor general, has never been shy about naming names...

Jun 21 , 2025

A well-worn adage says, “Budget is not destiny, but it is direction.” Examining t...