Abebech Tasew, 58, stood at the counter of the Qera Consumer Association last week, her expression reflecting the strain of dwindling purchasing power. As she scanned the prices, Abebech recounted the adjustments she had had to make to her shopping list, drastically reducing the volume of some items.

Sugar topped her list of concerns. Once accustomed to purchasing five kilograms for a little over 300 Br, Abebech now finds herself forced to slash her sugar purchases by threefold due to recent price increments.

"It's exceeded my budget," she told Fortune.

The mother of four now sees sugar as a luxury item. She can no longer afford to provide her children with tea sweetened with sugar or enjoy her coffee with the usual sweetness.

"We've had to learn to adjust," she said. "Like everything else."

Abebech's reality resonates with many residents of Addis Abeba. The city's consumers are feeling the pinch of a soaring inflation rate. Over the past two months, sugar prices have surged by over 30pc, leaving many households under financial strain.

Across the city's 152 consumer association outlets, the price of a kilogram of sugar has spiked from 63 Br to 95 Br. One outlet in Qirqos District, wereda 03, kebele 45, has been receiving less than half of its monthly demand of 13,000Qtl since the beginning of the year.

According to Bezawit Getachew, associate procurement head, the sudden price change two months ago has created a significant imbalance in the market. As people began to shy away from purchasing sugar due to the steep prices, daily sales plummeted by half. Consequently, the association has struggled to accumulate enough funds to make the next round of purchases.

"We've only managed to purchase a quarter of the demand," Bezawit said.

These issues come in the wake of pricing adjustments made by the federal government aimed at revitalising the flagging performance of the country's six operational sugar factories. However, a myriad of issues continue to plague these factories, ranging from high production costs and foreign currency shortages to security threats posed by armed groups.

A month ago, employees of the Wonji Shoa Sugar Factory, located 110Km from the capital, fell victim to armed resurgent groups, resulting in loss of lives. Despite its capacity to process 1.5 million quintals a year, the factory has been struggling with low sugarcane productivity and a shortage of foreign currency, which has undermined its output to 20pc.

Similar security issues afflict the Finchaa Sugar Factory in Horo Guduru Welegga Zone of Oromia Regional State, located 350Km away from the capital. Suspension of operations in May 2023 left around 9,000 employees idle for seven months following an attack by armed forces that caused damage worth 400 million Br and inflicted physical and emotional injuries on workers.

Mengistu Hailemariam, the general manager, shed light on the challenges of resuming operations. He cited technical problems with machinery in need of repair and inflated costs of chemicals, fertiliser, and spare parts, which have plummeted production to a mere fourth of its total capacity of 9,000tns a day.

"Our recovery is slow," he said.

Nearly 395Km from the capital lies the Arjo Diddessa Sugar Factory, located in the valley between East Wellega, Buno Beddelle, and Jimma zones in Oromia Regional State. Targeted by an armed group over a year and a half ago, the factory was forced to suspend operations for six months. Despite efforts to resume operations in April 2023, another attack resulted in 900 workers being transferred to other factories, effectively halting production.

Mijena Bekil, the general manager, expressed doubts about the factory's future, emphasising the unsafe conditions that make reinstating operations untenable.

"It'll be at least two years before we can consider reopening," he said.

Ethiopian Sugar Industry Group, overseeing eight factories, was formed in April 2022 with a capital of 115 billion Br. While some factories gained operational autonomy, others remained under the Group's management. However, constrained by high production costs and debt, over five sugar factories have appealed to the Group for a price increment, with costs soaring up to 400pc.

"Sugar will become a name if nothing is done soon," warned Weyo Roba, CEO of the Group while presenting a report to Parliament in December. He underscored the pricing disparities are half of what is offered in neighbouring countries and those imported through franco-valuta schemes.

"Such discrepancies are unsustainable," he cautioned.

Despite efforts by the ruling administration and previous governments to address the country's sugar consumption demand of close to 800,000tns, annual production has consistently fallen short, hovering at less than half the demand. While officials acknowledge the economic and political challenges, they point to systemic issues such as price rises on spare parts, fertiliser, and fuel, which have compounded the woes facing the sugar industry.

Reta Demeke, the public relations director of the Group, cited security concerns as a major impediment to meeting demand while admitting that the Group has barely managed to meet supply targets in the past year.

"Absence of security is our biggest challenge," he said.

In a country where sugar consumption per capita is around 10Kg, supply shortages persist, exacerbated by setbacks faced by several sugar factory projects due to funding shortages, climate conditions, and disputes with contractors.

This year's unprecedented climate conditions have rendered sugar cane cultivation impossible, leaving the Omo Kuraz III plant in the Southwestern Regional State barely producing any sugar. Located 900Km from the capital, with a daily production capacity of 10,000Qtl of sugar, the factory is part of a set of four sugar estates under development designed to process 24,000Qtl of sugar cane a day in the Omo Basin.

The history of the sugar industry in Ethiopia traces back to the 1930s with successive government regimes failing to realise self-sufficiency. Recent efforts to address these difficulties have included the privatisation of eight sugar factories. However, last year's attempt to privatise four sets of Omo Kuraz, Arjo Dediessa, Kesem, Tana-Beles, and Tendaho sugar factories saw limited success. Ethiopian Investment Holding (EIH) is engaged in renegotiations with interested bidders that were deterred due to issues related to security concerns and access to foreign currency.

Local industries heavily reliant on sugar have turned to imports to meet demand. In 2021, Ethiopia imported nearly 592 million dollars worth of sugar and sugar confectionery, a significant increase from three years prior.

The soft drink industry has shifted to imported sugar, as local supplies fall short. Moha Soft Drinks Plc, requiring over 38,000tns of sugar annually, has completely shifted its production of brands like Mirinda, Pepsi, and 7Up to imported sugar. Similar issues have been faced by Moya Biscuit S.C., a renowned biscuit manufacturer, which relies heavily on sugar for its daily production of 4,000 cartons of biscuits.

To address market imbalances, the Ministry of Finance revised sugar duties over two years ago, reducing taxes to zero for Franco Valuta importers. This move aimed to alleviate shortages, exempting them from tax duties, including customs and excise taxes.

According to a report from the Ministry of Trade & Regional Integration, imports through the schemes in the past eight months totalled 5.4 million quintals, surpassing local manufacturers' distribution, which stood at half a million quintals.

Kassaye Tiahun, tariff head of the Ethiopian Customs Commission, explained that these revisions aimed to alleviate local market shortages and curb inflation. However, these efforts coincide with a global downturn in sugar production, with prices rising by 20pc this year.

Experts believe addressing peace and security concerns is crucial for revitalising the sugar sector and attracting much-needed investment.

Economist Arega Shumete (PhD) observes significant challenges facing sugar production in Ethiopia, including political factors and corruption. He underscored instances where funds allocated for the expansion of sugar factories were misappropriated by previous federal authorities, hindering production and productivity.

Arega emphasised the vulnerability of many sugar factories to political instability and logistical disruptions due to their geographical remoteness. He is sceptical about the effectiveness of privatising these factories, citing ongoing issues with peace, security, and sector-specific policies. He suggested exploring alternative approaches, such as partial privatisation schemes and the formation of share companies, to attract investment and improve the industry's performance.

PUBLISHED ON

Apr 06,2024 [ VOL

25 , NO

1249]

News Analysis | Apr 20,2024

View From Arada | Jun 15,2024

Radar | Aug 05,2023

Commentaries | Jul 03,2021

Fortune News | May 14,2022

Radar | Jan 01,2022

Radar | Jan 15,2022

Fortune News | Feb 18,2023

Radar | Jul 24,2023

Dec 22 , 2024 . By TIZITA SHEWAFERAW

Charged with transforming colossal state-owned enterprises into modern and competitiv...

Aug 18 , 2024 . By AKSAH ITALO

Although predictable Yonas Zerihun's job in the ride-hailing service is not immune to...

Jul 28 , 2024 . By TIZITA SHEWAFERAW

Unhabitual, perhaps too many, Samuel Gebreyohannes, 38, used to occasionally enjoy a couple of beers at breakfast. However, he recently swit...

Jul 13 , 2024 . By AKSAH ITALO

Investors who rely on tractors, trucks, and field vehicles for commuting, transporting commodities, and f...

Jun 28 , 2025

Meseret Damtie, the assertive auditor general, has never been shy about naming names...

Jun 21 , 2025

A well-worn adage says, “Budget is not destiny, but it is direction.” Examining t...

Jun 14 , 2025

Yet again, the Horn of Africa is bracing for trouble. A region already frayed by wars...

Jun 7 , 2025

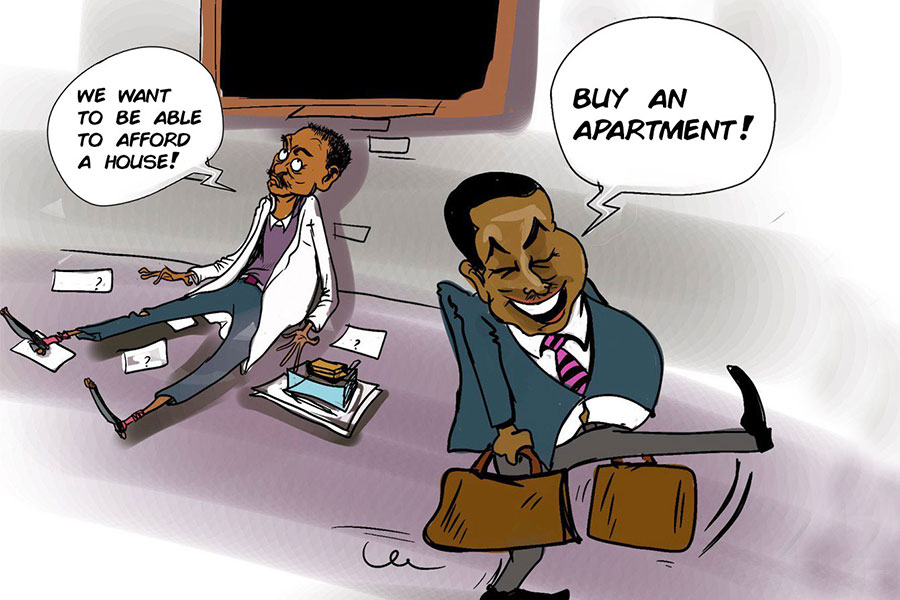

Few promises shine brighter in Addis Abeba than the pledge of a roof for every family...