Fortune News | Aug 31,2019

A pilot program to establish traceability for hides and skins throughout the leather value chain has been introduced by the Africa Leather & Leather Products Institute (ALLPI). Its proponents say that the initiative is a combined action between the public and private sectors to improve quality control and environmental care.

The traceability initiative will track hides and skins from their source, allowing stakeholders to identify and reward the highest quality materials. Set to launch as a one-year pilot, the program will involve stamping hides and skins with unique codes, enabling tracking from farms and slaughterhouses to processors.

The Institute is headquartered in Addis Abeba and operates under the Common Market for Eastern & Southern Africa (COMESA), working to boost Africa's leather industry. Representatives from 14 member states gathered three weeks ago in Bishoftu (Debre Zeit), Oromia Regional State, for a technical meeting on the planned tracking and certification systems.

Collectors have bought hides and skins at uniform prices previously. According to Nicholas Mudunguwe, executive director of the Institute, tanneries and leather processors will now be able to differentiate materials based on quality, introducing a payment model that aligns with product grade.

Paired with eco-certification, Nicolas believes this system aims to promote endurable practices within the leather industry. He lauds it as a critical step toward improving quality and ensuring fair compensation across the supply chain.

“We'll incentivise high-quality hide producers,” he said.

He is optimistic that after the one-year pilot, countries will recognise the benefits and adopt the model widely.

Ethiopia has a long-standing history in industrial leather production, dating back to 1925 with the establishment of Asco Tannery and the Darmar Shoe Factory two years later. The country’s livestock population—estimated at 65 million cattle, 40 million sheep, and 51 million goats—makes it a major player in Africa’s leather trade.

However, the sector faces difficulties. Kebede Amede, a leather technologist, notes declining quality as a major obstacle for exports. He said the 70pc high-grade leather products have dwindled to five percent high-grade standards, resulting in a drop from over 100 million dollars in revenue to less than 30 million. He attributed the decline largely to poor-quality raw materials.

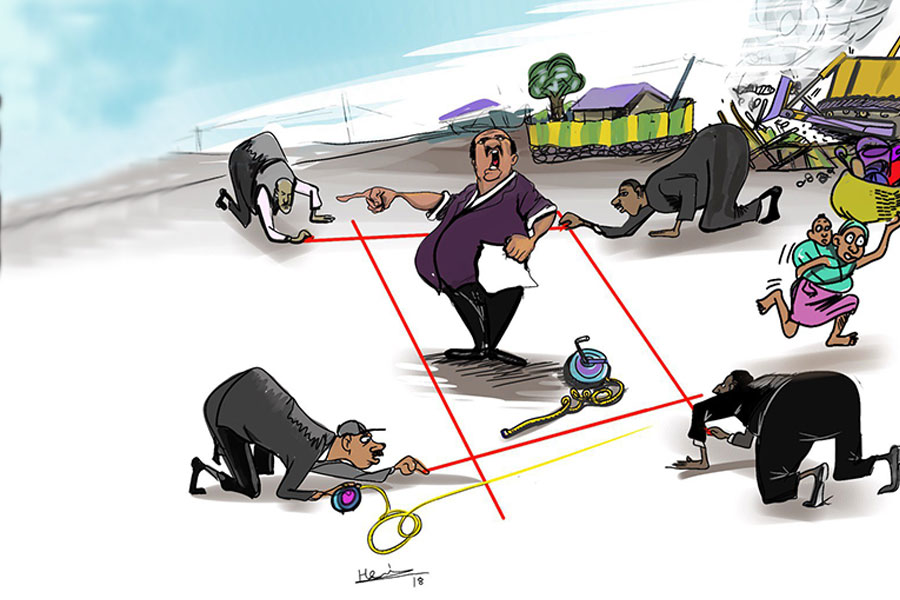

The fragmented regulatory structure exacerbates these issues, with oversight divided among the Ministry of Agriculture, Ministry of Trade & Regional Integration, and Ministry of Industry.

“There is currently no centralised body to enforce best practices,” said Kebede.

Shortages of chemical inputs, mismanagement, and inconsistent industrial salt availability compound the issues. However, stakeholders agree that raw material quality remains the industry’s primary hurdle, while financial constraints have resulted in only seven factories remaining operational out of the 35 factories under the Ethiopian Leather Industries Association (ELIA). Dagnachew Abebe, secretary-general of the Association, noted that Ethiopian highland leather is in demand internationally, while quality concerns hamper its competitiveness.

Last year, Ethiopia reported the slaughter of 20.52 million animals, yet industry experts argue that insufficient regulatory guidance has hindered efforts to improve quality standards.

The supply chain is strained with tanneries leaving the business. Exporters of raw hides and skins face additional concerns. Mesfin Legese, general board secretary of the Ethiopian Raw Hide & Skin Suppliers Association, underlined that the sector’s current hurdles include logistical constraints and security issues that impede collection efforts.

“The price of skins has stagnated while other sector costs continue to rise,” he said. “Manufacturers are increasingly selective, requiring credit terms.”

Suppliers have appealed for relaxed export restrictions, which mandate a minimum selling price of seven dollars per piece alongside a 150pc export tax. Mesfin noted that they buy skins at 50 Br to 80 Br and resell them to tanneries for 100 Br to 120 Br.

Challenges remain, particularly given Ethiopia’s reliance on traditional trading practices and the movement of livestock, which complicates tracking. However, the Ministry of Industry is partnering with the Institute to implement pilot projects at slaughterhouses, aiming to support the industry’s transition.

Kebede accentuated the need for a centralised regulatory authority and stringent quality control measures to rejuvenate the sector. He said the planned stamping of hides and skins with unique codes represents a foundational step in ensuring quality across the leather supply chain.

Industry stakeholders such as Mohamed Husen, acting manager at the Leather & Leather Products Research Development Centre, emphasize that quality control must begin at the earliest stages of the supply chain. They say that slaughterhouses and collectors should prioritise quality rather than focusing solely on export opportunities.

“We plan to reform the leather trade model,” he said. “Traceability is a key component.”

PUBLISHED ON

Nov 10,2024 [ VOL

25 , NO

1280]

Fortune News | Aug 31,2019

Fortune News | Aug 01,2020

Fortune News | Oct 02,2021

Radar | Jul 27,2019

Fortune News | Jun 12,2021

Viewpoints | Jan 11,2020

Radar | Nov 09,2024

Fortune News | Jul 18,2020

Fortune News | Feb 13,2021

Dec 22 , 2024 . By TIZITA SHEWAFERAW

Charged with transforming colossal state-owned enterprises into modern and competitiv...

Aug 18 , 2024 . By AKSAH ITALO

Although predictable Yonas Zerihun's job in the ride-hailing service is not immune to...

Jul 28 , 2024 . By TIZITA SHEWAFERAW

Unhabitual, perhaps too many, Samuel Gebreyohannes, 38, used to occasionally enjoy a couple of beers at breakfast. However, he recently swit...

Jul 13 , 2024 . By AKSAH ITALO

Investors who rely on tractors, trucks, and field vehicles for commuting, transporting commodities, and f...

Oct 11 , 2025

Ladislas Farago, a roving Associated Press (AP) correspondent, arrived in Ethiopia in...

Oct 4 , 2025

Eyob Tekalegn (PhD) had been in the Governor's chair for only weeks when, on Septembe...

Sep 27 , 2025

Four years into an experiment with “shock therapy” in education, the national moo...

Sep 20 , 2025

Getachew Reda's return to the national stage was always going to stir attention. Once...