Radar | Aug 26,2023

Strolling amidst the chaos of Qera, the persistent scent of freshly slaughtered livestock hung in the air. It was a scene where the commonplace hid the extraordinary—a product valued at over 400 billion dollars annually in the global industry.

An afterthought to most of the vendors in the area, sheepskin, goatskin and hides are either placed on the floor of the busy market or traded to middlemen who drive by each morning looking to sell to the 15 tanneries in Mojo town, Oromia Regional State, 64Km from the capital.

Being a sheep trader for most of his life, Abdulwahad Mohammed understood the ebb and flow of the market. He said the usually dormant market experiences sporadic surges in activity during holiday seasons, including a chance to deal hides. However, the quality of most pieces falls short of the standards required by discerning tanneries.

"It has a four Birr profit max," Abdulwahad told Fortune.

Ethiopia's livestock lives through the visible scars of a life marked by constant slashing, branding burns, and diseases bred amid poor hygiene. The traditional slaughtering techniques, coupled with a lack of post-slaughter preservation measures and transportation methods unsuitable for skin, contributed to the gradual deterioration of the final product.

Under the Addis Abeba Abattoirs Enterprise, around 2,427 oxen, 1,294 goats and sheep, and 15 cows were put to the knife for the Christmas holiday. It was a 19.1pc shortfall from the target where oxen fetched up to 200,000 Br while its hide was valued at around 200 Br. Sheep sold for an average of 15,000 Br garnered about 70 Br for skin while goatskin was valued at 10 Br despite the animal being sold for 20,000 Br.

The quality of hides and skins deteriorates by the day as tanneries seek a decent product to be competitive.

Colba Tannery, with its soaking capacity of 10,000 skins and 600 hides a day, once stood at the forefront of the industry. It had recorded sales close to 400 million Br during its peak years.

Despite its production prowess and a flourishing export market spanning 20 countries, the Company saw a steady decline in the supply chain. Employing a diverse set of methods to secure the 1.3 million sheep skins, over half a million goat skins, and 139,000 hides it needed annually, Colba maintained production amidst a shortage of chemicals, a lack of proper inputs, and the deteriorating quality of hides.

Kebede Amede is the chief technical advisor at Colba with experience spanning four decades and five tanneries. He attributed this decline to a lack of regulatory oversight and poor coordination between relevant government offices.

"Ethiopia's leather has no owners," he said.

Animal husbandry practices involving continuous beatings and branding with hot irons, coupled with subpar post-slaughter treatment, resulted in skins arriving at tanneries without any preservatives.

According to Kebede, skins arrive at tanneries multiple days after slaughter, without preservatives or salt used in between. He noted that the past decade marked the worst time for the industry, witnessing a decline in the quality of experts in public offices and a deprioritisation of the sector. He remarked on the government's role in enhancing the productivity of Ethiopia's leather industry, stating "All talk, little action."

As the industry lags, Ethiopia's merchandise exports in 2021/22 revealed a 9.1pc decline in leather and leather products, accounting for 0.8pc or around 32 million dollars of the 4.1 billion dollars in earnings.

A study 'Drivers of Quality Problems in the Leather Sector Value Chain in Ethiopia' identified low technology utilisation and low-quality, unreliable supply of raw hides and skins as major factors undercutting the industry.

Historical context reveals several regulatory organisations formed under different regimes to boost the leather industry. Emperor Haile Selassie's formation of the Livestock & Meat Board (LMB) in 1962 was followed by the National Leather & Shoe Corporation under the socialist regime which nationalised eight tanneries up until the Ethiopian People Revolutionary Democratic Front's (EPRDF) ratification of the hides marketing proclamation a decade ago. The current administration has also embarked on a new project spearheaded by the Ministry of Industry to unwind the supply, which is expected to serve as a major pillar in the import substitution aspiration.

The Ministry initiated the 'Ethiopia Tamirt' initiative to replace imports with domestically produced alternatives, crafting a leather industry strategy to address the issue.

Tilahun Abay, head of strategic affairs at the Ministry, is optimistic. He outlined plans for creating clusters to improve inputs, enhance foreign currency access, update customs procedures, and improve skills within the sector. According to Tilahun, some progress has been made, such as replacing leather shoes for the military and students with domestically produced ones.

"The country has not lived up to its potential," he said.

Value addition by each participant in the supply chain where an open and competitive market renders benefits across the board is suggested by officials as a long-term remedy.

Asmelash Berhe, director of dairy production at the Ministry of Agriculture, acknowledged market incentives as a significant issue, with prices for raw animal skins stagnant for nearly 15 years. He reasons that poor market incentives lay at the heart of the problem while quality has dropped as 95pc of slaughters happening within households do not possess adequate preservation measures for hides.

"At least 10pc of an animal's value should be in the skin," he told Fortune, indicating the dramatically low value.

Asmelash said that even at export duties of 150pc for raw hides and skins, millions of dollars continue to leave the country each year. He believes if tanneries begin buying with competitive prices, quantity and quality would improve.

Some producers resort to building their tanneries in a bid to bridge the supply gap in quality, consistency, and reliability.

For close to five million square metres of annual demand, the 89-year Anbesa Shoes S.C. built its tannery on 40,000sqm of land in Bahirdar City, Amhara Regional State.

Hailekiros Debesay, the manager, calls for the need for national awareness of animal husbandry and slaughter techniques to harness Ethiopia's potential in the industry. He said most tanneries going out of business, while the rest lag in leather exports due to the small number of colour options.

"There is a serious problem," he told Fortune.

Cattle traders like Hassen Mohammed faced immediate concerns. Nestled in German Avenue in Nifas Silk Lafto District, he is among the few whose market was demolished to make way for development projects. He does not seem too concerned about animal hides that merely fetch below 10 Br profit. Inflation and a decline in sales are among Hassen's immediate worries for providing for his 14-member family.

"I'm not quite sure how to be a provider anymore," he said, pointing to the pile of sticks and corrugated tin roofs plastered across the muddy field.

The 1,000-member-strong Addis Abeba Abators Association advocated for reconsidering the 15pc tax on meat slaughters to support the industry amidst inflation. Under the watchful eye of the Enterprise, members of the Association supply hides every week, which will be auctioned off to the rapidly diminishing number of tanneries.

Ayele Sahle, president of the Association, emphasised the need for a collaborative approach and utilising every part of the animal for foreign currency generation.

"There is an alarming level of disregard for the sector," he said.

In an evolving global industry whose products involve footwear to sofa upholstery, Ethiopia's leather industry faces headwinds in poor technology adoption, a dearth of skills and a lack of strategic markets, with a formidable population of above 168 million four-legged livestock resources.

International experts have a different outlook.

The days of the leather industry returning to its glory seem unlikely for Wondu Legesse. He cautioned against a myopic analysis, noting a global shift towards synthetic leather due to changing demand driven by environmental-friendliness and affordability. Wondu urged policymakers to adapt to evolving technology and demand.

"Ideological and technological shift is underway," he told Fortune.

He recommends a reorientation of the supply chain predicated on tailoring to the needs of the end user. An emphasis towards the absorption of processed hides by manufacturers should be given while heavy investment in technology is required to compete with international markets.

"Policy creation should not heed the confused perspectives of the many disgruntled stakeholders," Wondu said.

PUBLISHED ON

Jan 13,2024 [ VOL

24 , NO

1237]

Radar | Aug 26,2023

Fortune News | Jun 24,2023

Featured | May 28,2022

Radar | Dec 16,2023

Fortune News | Dec 01,2024

Radar | Oct 27,2024

Fortune News | Apr 12,2020

Commentaries | Jan 26,2019

Viewpoints | Sep 04,2021

Advertorials | May 30,2025

Dec 22 , 2024 . By TIZITA SHEWAFERAW

Charged with transforming colossal state-owned enterprises into modern and competitiv...

Aug 18 , 2024 . By AKSAH ITALO

Although predictable Yonas Zerihun's job in the ride-hailing service is not immune to...

Jul 28 , 2024 . By TIZITA SHEWAFERAW

Unhabitual, perhaps too many, Samuel Gebreyohannes, 38, used to occasionally enjoy a couple of beers at breakfast. However, he recently swit...

Jul 13 , 2024 . By AKSAH ITALO

Investors who rely on tractors, trucks, and field vehicles for commuting, transporting commodities, and f...

Jun 28 , 2025

Meseret Damtie, the assertive auditor general, has never been shy about naming names...

Jun 21 , 2025

A well-worn adage says, “Budget is not destiny, but it is direction.” Examining t...

Jun 14 , 2025

Yet again, the Horn of Africa is bracing for trouble. A region already frayed by wars...

Jun 7 , 2025

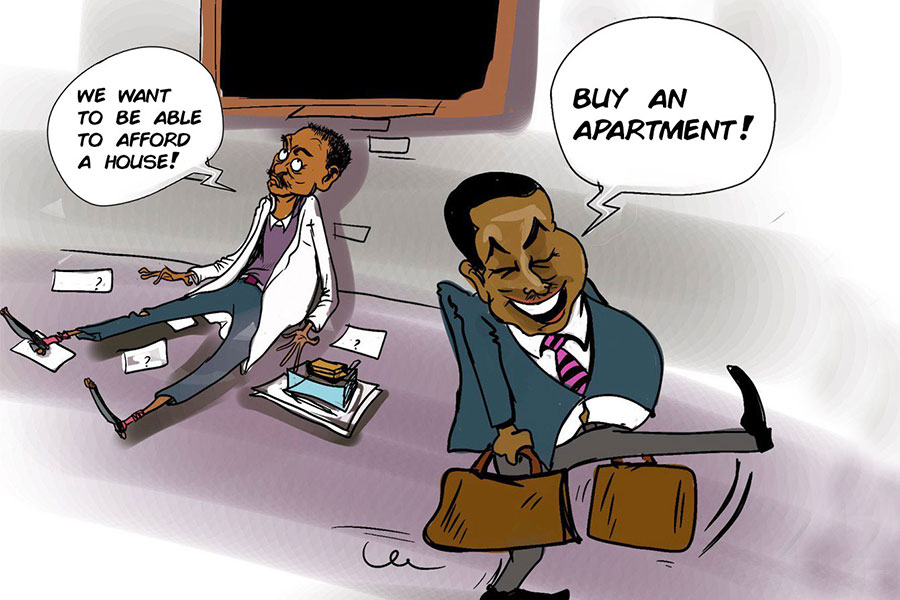

Few promises shine brighter in Addis Abeba than the pledge of a roof for every family...