Editorial | Dec 07,2024

Genet Gemchu, who is in her early '30s, did not find raising her youngest child as easy as her experience raising her four-year-old.

Genet, who has worked at East Africa Pharmaceuticals Plc since 2014 and lives in the Goro area, finds diapers to be one of the major expenses of her family.

Genet changes her 10-month-old baby's diapers four times a day. She buys diapers every other week, spending 840 Br a month at a pharmacy in her neighbourhood.

While buying diapers, Genet, who got married six years ago, considers its absorbency and softness.

"Since baby skin is sensitive," said Genet. "I have to be very careful when I buy diapers."

Though baby diapers were invented in the 1930s, the product has continuously improved. Today’s disposable diaper is light, compact, very absorbent, resistant to leaks and easy to use. In Ethiopia, too, the trend of using mass-produced diapers for babies is becoming common.

However, the percentage of diaper users stands at only five percent in Ethiopia, while in Kenya, diaper users are more than 70pc of the population.

Different types of diapers manufactured around the globe include cloth diapers, disposable diapers, training nappies, swim pants and biodegradable diapers.

The value of the baby diaper market is estimated to be worth approximately 70.4 billion dollars worldwide by 2024. This is an increase of over 20 billion dollars over the eight-year forecast period. Disposable baby diapers lead the diaper market, holding around 65pc of market share. North America and Europe together account for more than 50pc of global baby diaper production.

Canbebe diapers are manufactured by ONTEX Hygienic Disposables Plc at Hawassa Industrial Park. The company supplies 40pc of its products to the local market while exporting 60pc to the East African market and other sub-Saharan countries.

Previously, many local families have been using imported diapers, but these days they are starting to use locally-produced items. In 2017 Ethiopia imported 4.9 million kilograms of diapers from China, Turkey and Egypt.

Kedeme Gebere, a father of four kids and an employee of the African Union who lives in Gerjji, is one of them. He recently shifted to locally-produced products.

He uses Canbebe diapers for his newborn baby. Three of his older children used Pampers until they were two and a half years old.

Kedeme buys a pack of Canbebe diapers containing 44 pieces for 306 Br, which lasts him up to ten days, from All-Mart Supermarket located in his neighbourhood.

Manufactured by ONTEX Hygienic Disposables Plc, Canbebe has been distributed in Ethiopia since 2010. But the company started production locally in 2017 at a plant located at Hawassa Industrial Park in which it invested a quarter of a billion Br.

The Turkish company manufactures the product in partnership with an Ethiopian firm, Tracon Trading Plc.

ONTEX supplies 40pc of its product to the local market while exporting 60pc to the East African market and sub-Saharan countries that are members of the Common Market for Eastern & Southern Africa (COMESA).

The company's products are produced under five categories using different raw materials, according to Feven Gutu, trade marketing specialist at Ontex Global.

Leakage protection baby diapers, which prevent leaks around the waist and the legs; stay dry baby diapers designed to offer up to 12 hours of wetness protection; soft baby diapers for babies with sensitive skin; thin and flexible diapers for babies who are active and love to move around; and perfect fit diapers that focus on comfort are the types of products produced by Canbebe.

Employees pack Canbebe diapers at Hawassa Industrial Park, where the company invested 250 million Br in its factory.

Lilac Sanitary Napkins & Baby Diapers Manufacturing Enterprise, ABC Diaper and Baby Time Diaper Manufacturing Factory are among the plants that manufacturer diapers locally.

Canbebe's prices range from 300 Br to 650 Br depending on size and the number of diapers in a pack. The company's products can be used by newborns to toddlers.

Lilac is another local manufacturer that joined the business in 2016 with a production capacity of making 400 baby diapers a minute at its plant located behind Kality Prison.

Lilac's products have a colour-changing wetness indicator that alerts parents when it’s time to change. The indicator changes colour from yellow to green when the diaper gets wet.

The back layer of the diaper is re-usable, and the part which has direct contact with the baby is lubricated with olive oil to protect babies from allergies.

Moyze Abas, a managing consultant at Lilac, says that diaper products have a huge demand locally, especially from the regional states.

But the company finds it hard to produce at full capacity due to electric power interruptions and lack of foreign currency to import raw materials, according to the managing consultant.

“Currently, we are operating with only 40pc of our capacity," said Moyze.

The rise in urbanisation is driving the growth of the market, according to Moyze.

He says that if the local companies can manage to get support from the government, they can meet the domestic demand and substitute for the imported products.

Not only disposable but also reusable diapers are manufactured locally. Baby Time Diaper Manufacturing Factory, a reusable diaper manufacturer that entered the market two months ago with 30 employees and a capacity of producing 1,500 diapers a day, is one of them.

The company, which imports the raw materials from China, sells a five-pack of its Baby Time diapers for 190 Br.

The company targets low-income parents, according to Fuad Mehammed, owner of Baby Time.

Fuad says that even though the demand for the product is increasing, there is still a lack of awareness by the society on the use of reusable diapers.

The reusable diapers have a life span of at least six months, and the products are relatively cheaper.

Just like Lilac, Baby Time is also facing a challenge in obtaining foreign currency to import raw materials for manufacturing.

Mulugeta G. Medhn (PhD), a lecturer at Addis Abeba University's School of Commerce, believes that there is a high potential for an increase in demand for diapers and the existing local companies are not enough to meet the demand.

The local manufacturer, to compete with the imported products, has to diversify their business and product lines and work aggressively on distribution mainly in the regional part of the country, according to Mulugeta.

"Until the forex problem is solved, the manufacturers should diversify their business into manufacturing exportable products to generate the forex needed to import the raw material," Mulugeta recommended.

PUBLISHED ON

Oct 19,2019 [ VOL

20 , NO

1016]

Editorial | Dec 07,2024

Radar | Dec 21,2019

Fortune News | Jan 27,2024

My Opinion | Oct 30,2021

Commentaries | Mar 07,2020

Agenda | Sep 22,2024

Agenda | Apr 30,2021

Viewpoints | Sep 01,2024

Fortune News | Jun 20,2025

Commentaries | Mar 25,2023

Dec 22 , 2024 . By TIZITA SHEWAFERAW

Charged with transforming colossal state-owned enterprises into modern and competitiv...

Aug 18 , 2024 . By AKSAH ITALO

Although predictable Yonas Zerihun's job in the ride-hailing service is not immune to...

Jul 28 , 2024 . By TIZITA SHEWAFERAW

Unhabitual, perhaps too many, Samuel Gebreyohannes, 38, used to occasionally enjoy a couple of beers at breakfast. However, he recently swit...

Jul 13 , 2024 . By AKSAH ITALO

Investors who rely on tractors, trucks, and field vehicles for commuting, transporting commodities, and f...

Jun 28 , 2025

Meseret Damtie, the assertive auditor general, has never been shy about naming names...

Jun 21 , 2025

A well-worn adage says, “Budget is not destiny, but it is direction.” Examining t...

Jun 14 , 2025

Yet again, the Horn of Africa is bracing for trouble. A region already frayed by wars...

Jun 7 , 2025

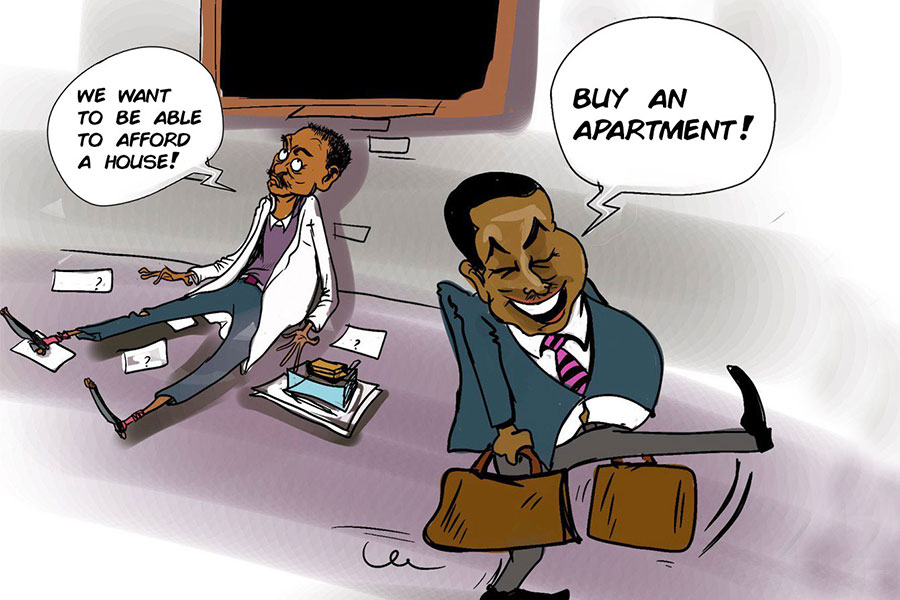

Few promises shine brighter in Addis Abeba than the pledge of a roof for every family...