Fortune News | Apr 03,2021

Cement factories have been producing below half their capacity, compelled by security concerns and limited input supplies, indicating a significant shortfall in the construction sector.

The industry has been plagued with production and distribution challenges. Despite the attempt to take stringent regulatory measures by officials on the distribution line, the scarcity in the market has been apparent with a supply that could not keep up with the demand.

Annual demand is estimated to have reached 36 million tons, with 18 cement plants having an aggregate production of 7.5 million tons. The production has dropped 60pc below the target.

During a nine-month report presented to Parliament two weeks ago, Habtamu Tegegn, minister of Mines, attributed the declined production to conflicts erupted near the plants, restricted foreign currency and limited input supplies such as coal.

"The fundamental problem lies in production," said Habtamu.

Last year, eight factories received licenses from the Ministry to begin coal manufacturing, the backbone of cement production. The initiative was hoped to alleviate the 1.5 million tons demand.

Although the country has resources, the lack of a proper feasibility study and shortfall in considering the environmental effects had impeded the production, according to Habtamu.

The highest production volume was recorded five years ago when 20 plants produced 12.7 million tons. The annual average per capita cement consumption stands at 58kg, which has been relatively stagnant over the last five years as the construction industry faced constraints and low purchasing power.

State Minister for the Ministry of Urban Planning & Infrastructure, Wondimu Seta, said although exporting cement to neighbouring countries was on their radar, factories are struggling even to cover half the local demand.

One Corporation facing the predicament is the Ethiopian Construction Works Corporation (ECWC) with over 50 construction pending projects. It has received less than 30pc of the yearly demand for two million tons.

According to the CEO, Yonas Ayalew, the distribution chain is predominated by intermediaries.

The Corporation has been working with five cement plants with only Derba and Dangote, the largest cement factories, meeting the demand.

Yonas has plans to engage with international manufacturers to avoid the bottlenecking supply.

The Corporation, established in 2015 with over 7.7 billion Br paid-up capital, is now one of the 38 state subsidiaries under the Ethiopian Investment Holdings.

The skyscraper view of the capital reveals incomplete infrastructure projects. Ethiopian Construction Authority is tasked to monitor 90 public construction projects where 70pc have been paused for the past two years.

According to Abebe Banjaw, the building regulation director at the Authority, the mounting prices of steel and cement have contributed to the unfinished projects with a power disruption and security issues inhibiting factories from production.

Factories cite the substandard quality of inputs as the reason for the diminished production.

Kuyu Cement Factory, incorporated in 2014, has a daily production capacity of nearly 1,500 clinker daily, selling to the local markets at a 750 Br price for a quintal. The factory has produced a quarter of its capacity for the past few years. They source input from Jimma and Arjo towns. Birhanu Digafe, the supply manager, said the logistics hurdles have contributed to the shortages.

"The substandard quality of inputs also diminished production," he told Fortune.

He said they are striking deals with the Petroleum & Energy Authority to import coal from Djibouti.

"We will import the inputs onward," he said.

Experts recommend quality control should be given due attention while facilitating investment incentives for manufacturers to enter the industry.

Abebe Dinku (PhD), a civil engineer at Addis Abeba University, observes the possibility of some plants decreasing their production capacity deliberately to increase profitability and avoid hounding costs.

He recommends regulators focus on quality as the expectation for factories to work at full capacity is far-fetched.

“More factories with large manufacturing capacities should be underway," said Abebe.

PUBLISHED ON

May 20,2023 [ VOL

24 , NO

1203]

Fortune News | Apr 03,2021

Sunday with Eden | Jun 01,2019

Viewpoints | Jan 07,2023

Radar | Jan 26,2019

Fortune News | Sep 28,2024

Fortune News | Jun 01,2019

Radar | Mar 16,2024

Radar | Jun 19,2021

Radar | Dec 05,2020

Sunday with Eden | May 27,2023

Dec 22 , 2024 . By TIZITA SHEWAFERAW

Charged with transforming colossal state-owned enterprises into modern and competitiv...

Aug 18 , 2024 . By AKSAH ITALO

Although predictable Yonas Zerihun's job in the ride-hailing service is not immune to...

Jul 28 , 2024 . By TIZITA SHEWAFERAW

Unhabitual, perhaps too many, Samuel Gebreyohannes, 38, used to occasionally enjoy a couple of beers at breakfast. However, he recently swit...

Jul 13 , 2024 . By AKSAH ITALO

Investors who rely on tractors, trucks, and field vehicles for commuting, transporting commodities, and f...

Jun 28 , 2025

Meseret Damtie, the assertive auditor general, has never been shy about naming names...

Jun 21 , 2025

A well-worn adage says, “Budget is not destiny, but it is direction.” Examining t...

Jun 14 , 2025

Yet again, the Horn of Africa is bracing for trouble. A region already frayed by wars...

Jun 7 , 2025

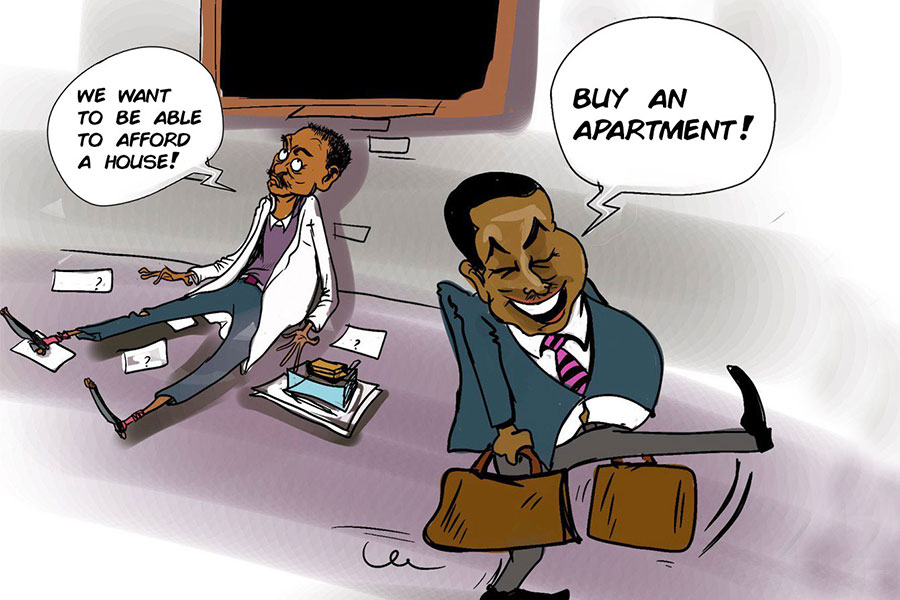

Few promises shine brighter in Addis Abeba than the pledge of a roof for every family...