Fortune News | Aug 23,2025

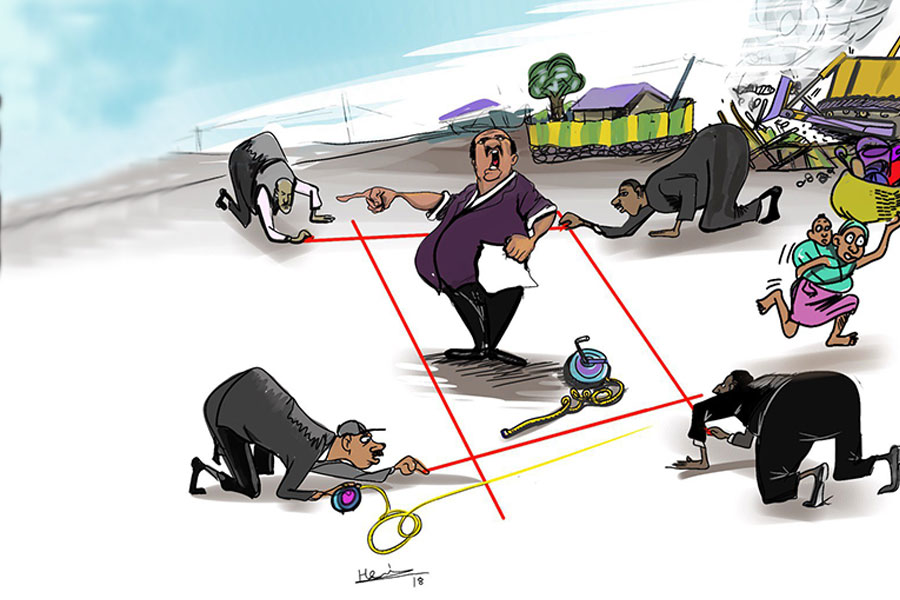

The chronic cement shortage haunting markets and the ensuing soaring prices have taken their toll on the progress of public construction projects. Executives of state-owned enterprises say several projects are facing delays. Although it is not the only factor, the cement shortage is the main reason.

Retail prices have surged to 2,000 Br a quintal from under 500 Br two years ago. Rules forcing the 10 cement factories to hand over 146,000tns daily production to public projects have proved ineffective. The remaining 30pc is distributed through wholesalers and youth associations, which retail cement to users. Depending on distances, factories sell a quintal of cement to designated distributors between 770 Br and 870 Br.

Trade officials from regional states lodged complaints to the Trade Ministry over shortages, which have worsened after the latter introduced a directive two months ago. The directive forced cement factories to sell directly to state entities and institutional buyers. The Construction Works Regulatory Authority, the federal agency supervising and evaluating progress on public projects, asked state entities to submit projections on cement demand. Agencies and enterprises undertaking 76 projects requested 145,000tns of cement.

The high demand, 126,000tns, came from 10 public agencies undertaking 58 projects. Among them was the state-owned Commercial Bank of Ethiopia (CBE), which has 16 building projects across the country. Its executives say they require nearly three tonnes of cement for three months of construction work. However, the Authority has approved only a quarter of the initial request.

The Bank inaugurated its 48-story headquarters in April this year with 304 million dollars in investment. It took China State Construction Engineering Corporation Ltd six years to complete the construction.

Established in 2015, Oda Bultum University is one of the public entities with 39 ongoing projects, of which 26 were expected to be completed last year. The projects include dormitories, dining rooms, libraries, and classrooms. The cement shortage caused delays, according to Andinet Abebe, project manager.

The University’s administrators requested the Authority for 10,000tns of cement for the three months. Officials approved a little more than half this volume. The University will receive the cement after the Trade Ministry gives the go-ahead, disclosed Endalew Temesgen, the construction supervision office manager.

Among the 11 public universities opened in the last decade in West Harerghe Zone, 325Km southeast of the capital, Oda Bultum runs seven colleges, two institutes, and a school. The University enrols over 4,000 students in 32 undergraduate programmes.

The 41 public universities are undertaking close to 400 projects with an outlay of 100 billion Br. Several of these face delays and suspensions due to a shortage of construction inputs; surging prices are causing unforeseen variations in the bill of materials. Federal authorities approved the injection of billions of Birr to contractors undertaking public projects to shield them from rising costs. However, most contractors have yet to see their contracts adjusted.

TNT Construction Plc handles four projects in Oda Bultum University, including building classrooms and lecture halls. These projects require 60tns of cement a week, according to Zelealem Tesfaye, division head.

“But we’re getting less than half,” he told Fortune.

TNT Construction handles over 10 public projects, including Ambo Referral Hospital and Bulbula West Water Treatment Plant. In business for 17 years, the company built the ruling Prosperity Party (PP) headquarters erected in the Arat Kilo area.

Zelealem has observed that cement factories prefer to sell cement independently instead of supplying it directly to public projects.

Factories are told to sell a quintal of cement to contractors handling public projects at 900 Br, excluding transportation and other costs. But the retail prices of a quintal of cement have now passed the 2,000 Br mark.

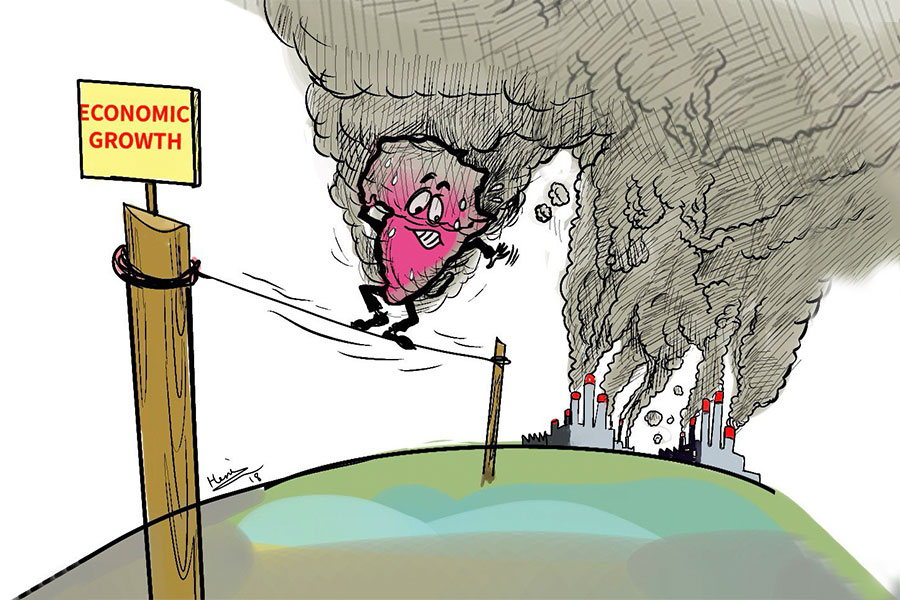

Over 10 cement plants have an aggregate production capacity of 8.4 million tonnes annually. Annual demand for cement is estimated to have reached 12 million tonnes. Mohammed Al- Al-Amoudi (Sheik) and his family owns Derba Cement remains the largest plant producing 2.5 million tonnes, followed by Dangote’s 2.3 million tonnes.

Getie Andualem (PhD), a lecturer at the Addis Abeba University College of Business & Economics, suggests the government should focus on enabling the cement industry to boost production as a short-term solution.

“As a long-term solution, the government should work on attracting foreign investors,” said the expert.

Established in 1984, the state-owned Mugher Cement is one of the seven factories expected to supply mainly to public projects and state-owned enterprises. It is expected to supply over 16,000tns of cement to public projects monthly.

“We’re supplying based on the quota,” said Gezahegn Dechasa, general manager.

Executives of cement factories, however, say they are using less than half of installed capacities due to a shortage of coal and the rise in fuel prices.

PUBLISHED ON

[ VOL

, NO

]

Fortune News | Aug 23,2025

Radar | Sep 11,2020

Radar | Mar 11,2023

Radar | Jun 08,2019

Fortune News | Oct 02,2021

Radar | Oct 15,2022

Radar | Dec 28,2019

Viewpoints | Dec 17,2022

Fortune News | Jun 29,2024

Radar | Apr 13,2019

Dec 22 , 2024 . By TIZITA SHEWAFERAW

Charged with transforming colossal state-owned enterprises into modern and competitiv...

Aug 18 , 2024 . By AKSAH ITALO

Although predictable Yonas Zerihun's job in the ride-hailing service is not immune to...

Jul 28 , 2024 . By TIZITA SHEWAFERAW

Unhabitual, perhaps too many, Samuel Gebreyohannes, 38, used to occasionally enjoy a couple of beers at breakfast. However, he recently swit...

Jul 13 , 2024 . By AKSAH ITALO

Investors who rely on tractors, trucks, and field vehicles for commuting, transporting commodities, and f...

Oct 4 , 2025

Eyob Tekalegn (PhD) had been in the Governor's chair for only weeks when, on Septembe...

Sep 27 , 2025

Four years into an experiment with “shock therapy” in education, the national moo...

Sep 20 , 2025

Getachew Reda's return to the national stage was always going to stir attention. Once...

Sep 13 , 2025

At its launch in Nairobi two years ago, the Africa Climate Summit was billed as the f...