Fortune News | Apr 26,2019

His phone is tightly wrapped up in a plastic bag and tied around his neck. The bag is meant to keep dust from getting in and damaging the phone, but after a full day's work, the thin plastic is no match for the quintals of cement he carries on his back. The rest of Yohannes Biset's body is doused with cement day in and day out. But he brings with him a change of clothes, wrapped up in yet another plastic bag. This one is safe from cement, sitting all the way in the back of the warehouse where he spends his days loading and unloading cement.

The cement business has been particularly turbulent over the past months; new laws have taken precedence, prices have soared ever higher, and shortages in production have rewarded those with the right connections handsomely, while those who are not so lucky have been hung out to dry. The only constant, it seems, is Yohannes' pay: a measly three Birr for each quintal carried. He is not complaining too much though. At least there is the cement to carry, he admits.

"It hasn't been as good as a couple of years back," said the 25-year-old, who has earned his living carrying cement for seven years. "But it's still better than a few months ago."

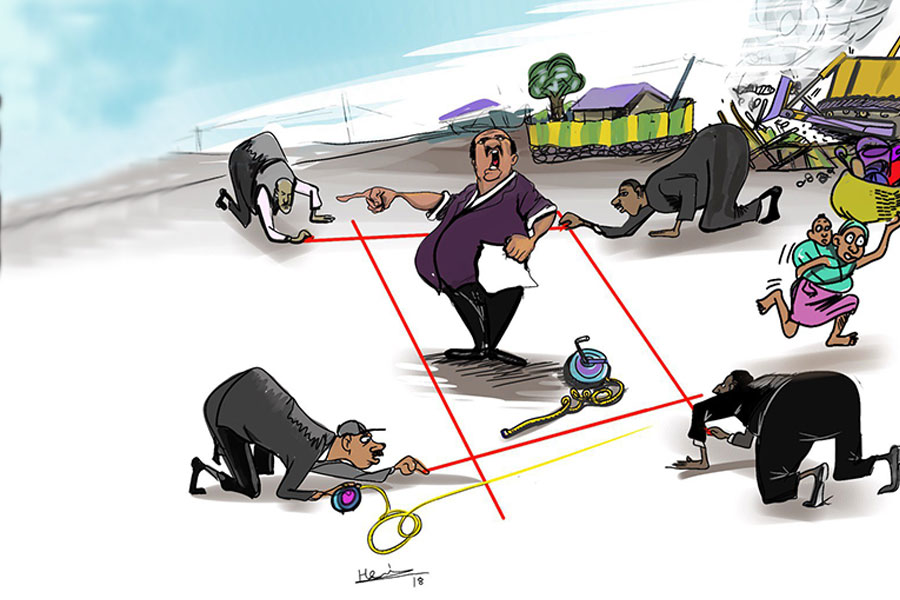

He is referring to the time when cement shortages reached their pinnacle around six months back. Since then, the playing field has changed with major policies imposed by the government to alleviate supply deficits in the industry. Wholesalers of cement, which had been limited to only six hand-selected companies during the previous policy, saw their ranks swell to around 80. A new law, freshly minted by the Ministry of Trade & Industry, hit the streets with aspirations of avoiding unnecessary price increases on the product and lifting price caps at cement retail shops. But what had appeared to be the light at the end of the tunnel now seems more like the proverbial headlights; and the construction industry, like the deer in the road.

An illustrative example is the priority given to government projects. When the directive came out at the end of August last year, companies engaged in public works were granted the option to source their cement not from wholesalers, where waiting times can stretch for months, but directly from factories.

Equatorial Construction Plc, a grade-one contractor active in the business for over a decade and currently working on two urban water supply projects in the country, has yet to receive any exceptional treatment promised in the directive.

Water reservoirs, housing and other components in the project involve a substantial amount of structural work. They need large amounts of cement, according to Dawit Gebrekidan, general manager of the company.

Multiple visits to government offices over the past five months have yet to solve the problem. What is more surprising is that the company has been in the queue for nearly the same amount of time to get cement from its assigned official wholesaler, Biftu Adugna Business S.C., one of the six original distributors. The wholesalers have yet to spare a quintal for the contractor's water projects in a country where less than 60pc of the population has access to safe drinking water.

"We've been waiting in line since then," said Dawit. "The response we're getting is that there isn't enough cement being produced." Pausing projects is out of the question as it has even more severe repercussions. The cement price has also doubled since the company took on its two latest projects 10 months ago.

The company, which normally handles projects with average costs of around 100 million Br, is currently satisfying its cement needs through retailers at prices above 500 Br a quintal, almost double the factory and wholesale prices. Receipts for transactions from retailers are hard to come by, according to Dawit. The industry has largely gone underground, with receipts eschewed at all costs.

Long queues at wholesalers for cement have forced retailers to close up their shops on Megenagna road, one of the city's cement retail hubs.

But retailers across the city, displeased to no end, have their own justification. They are getting their cement at equally exorbitant prices, through brokers who themselves provide no receipts. It is either this or close up shop until their own long-awaited turn for supply comes around. The closed-up cement retail shops outnumber the open ones three-to-one on Megenagna road, one of the city's cement retail hubs.

The rest are selling black market cement for a profit of five or 10 Br profit a quintal. Their frustration over the prices is only overshadowed by their skepticism about the government's ability to respond to their calls.

"We've tried appealing at multiple government organisations," said one retailer who chose to remain anonymous. "[The government] is either unable or unwilling to fix this."

Long queues are still unsolved today; and even though cement is now relatively available, it comes at a costly price. The growing local cement demand is estimated at 13 million tonnes annually with a production capacity of 8.5 million tonnes across the 14 factories in the country.

Long waits and unstable prices aside, the cement shortage now may hamper the expectations for construction progress that the dry season had brought with it. Progress and customer satisfaction on delivery is emphasised none more so than in markets like real estate, a booming business in the country. Housing accounts for a major portion of the total cement demand - approximately 60pc to 65pc.

However, not even well-established names like Noah Real Estate Plc and Flintstone Engineering, the construction firm behind Flintstone Homes, are immune to the cement industry's issues.

Flintstone Engineering, currently handling 20 projects worth over seven billion Birr and predominantly engaged in structural works, has capped its needs at 2,000ql a month to deal with the shortage, according to Mogess Tadesse, general manager at the real estate firm.

Idle employees, for a company that has a payroll of three million Birr just for daily labourers, have also brought on a high cost. In the worst cases, the firm is forced to let go of short-term employees.

"The work we do should at least cover our costs," said Mogess. "The satisfaction of our clients on our delivery is very important, and we have to keep going."

The price cap for retailers in a supposedly free market was wrong to begin with; but more importantly, this is not where the problem stems, as far as Mogess sees it.

Just as it does anywhere, financial capacity comes in handy in this situation. Some companies overbuy; order more than what they need and pay upfront for stock at every major supplier and factory. They use up one supply as their other orders slowly come around. Even so, few are spared from buying from retailers to fill gaps every now and then.

Their government counterparts have not been idle either. A study was done on the industry prior to the legal changes that took place in August. The Chemicals & Construction Input Industry Development Institute, working alongside major government stakeholders, had initiated efforts to increase the production capacity of cement producers in the country, which stood at just 50pc in September.

The goal was to get this to 65pc by October, and that was achieved, according to Simegn Degu, director of cement & related industry research & technology development at the Institute.

The study identified problems like lengthy distribution channels, foreign currency shortages for buying spare parts at cement factories, and security threats at factory sites as the biggest challenges facing production.

"Power cuts were a big obstacle for the factories, as was identified by our assessment," he said. "Hence, we worked on creating substations for nearly all the producers."

The retail price cap was also lifted to understand that it had only resulted in hoarding, and government interference wasn't helpful. A forex allocation of 85 million dollars was assigned for spare part purchases at the factories.

The Ministry had similarly announced lifting the ban on importing cement, allowing Franco Valuta permits and exemptions of import tax for those interested in import. So far, there have been no imports of cement into the country.

The sector, closed to foreign investment until recently, has opened up on that front as well.

But it has not been without its setbacks. Conveyor belts, which can span up to seven kilometres from quarry sites and are an essential part of cement factory operation, broke down at Mugher and Dangote cement factories due to landslides in the area.

Messebo Cement in Tigray Regional State, currently the largest modern cement plant in the country, is temporarily out of the picture due to the conflict in the Regional State.

Import substitution for coal, a crucial component of modern cement production, has been initiated in areas like western Oromia and Beninshangul-Gumuz regional states. Still, instability has put limitations there as well.

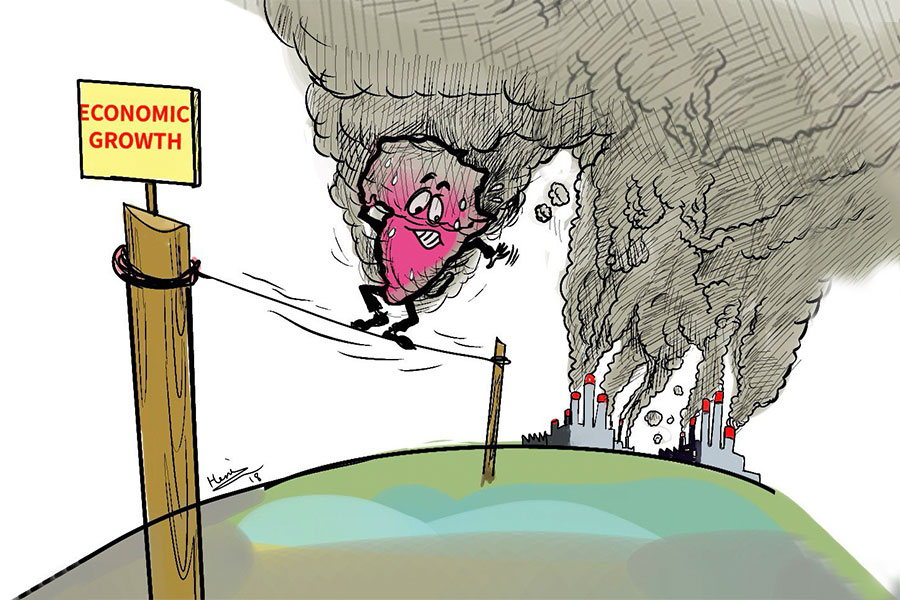

Experts believe that if the shortage runs this deep when the economy is at a slow pace due to the Novel Coronavirus (COVID-19), it can only grow worse as activity picks up.

"There's a great deal of construction happening," said Denamo Addissie (PhD), assistant professor at the Ethiopian Institute of Architecture, Building Construction & City Development at Addis Abeba University. "Our cement needs can only grow from here."

The price hike is only natural as there is a shortage of the product on the market, according to the expert, but he believes that some form of government intervention is still warranted.

"The market is not stable yet," he said. "We need strong institutions that can stand up and protect the interests of different players in the chain for this to happen."

However, the government needs to conduct studies on the supply chain, according to him. Denamo also believes, like the vast majority of retailers, that intermediaries should be cut out of the equation, at least for a while. Buffering the production capacity at factories is definitely one way to go, he added.

As for strong institutions that can work toward protecting group interest, this is something that daily labourers like Yohannes also think about often. With housing and food costs inching a bit further out of reach by the day, he understands that unionising is the better option to obtain a pay raise, but many obstacles stand in the way.

"There are many worse off than me," he said. "The shops can easily replace those of us working now."

Local IDs are also hard to get, even for Yohannes, who left Lalibela, 800Km away, to work in the capital years ago. For now, he is betting on the cement-covered, faux gold cross on his neck to protect him. It seems that no one else can.

PUBLISHED ON

Jan 16,2021 [ VOL

21 , NO

1081]

Fortune News | Apr 26,2019

Featured | Jan 11,2020

Radar | Apr 13,2019

Agenda |

Commentaries | Oct 28,2023

Radar | Jul 23,2022

Fortune News | Jul 06,2025

Fortune News | Oct 22,2022

Radar | Mar 23,2019

Fortune News | Feb 26,2022

Dec 22 , 2024 . By TIZITA SHEWAFERAW

Charged with transforming colossal state-owned enterprises into modern and competitiv...

Aug 18 , 2024 . By AKSAH ITALO

Although predictable Yonas Zerihun's job in the ride-hailing service is not immune to...

Jul 28 , 2024 . By TIZITA SHEWAFERAW

Unhabitual, perhaps too many, Samuel Gebreyohannes, 38, used to occasionally enjoy a couple of beers at breakfast. However, he recently swit...

Jul 13 , 2024 . By AKSAH ITALO

Investors who rely on tractors, trucks, and field vehicles for commuting, transporting commodities, and f...

Oct 4 , 2025

Eyob Tekalegn (PhD) had been in the Governor's chair for only weeks when, on Septembe...

Sep 27 , 2025

Four years into an experiment with “shock therapy” in education, the national moo...

Sep 20 , 2025

Getachew Reda's return to the national stage was always going to stir attention. Once...

Sep 13 , 2025

At its launch in Nairobi two years ago, the Africa Climate Summit was billed as the f...