Addis Abeba is facing a severe cement supply shortage now that the stocks of many retailers and wholesalers are depleted because of disruptions in the supply chain.

Chronic cement supply shortages have been recurring in the capital since February. But the situation has worsened over the past three weeks, according to retailers, who said that they only have a minimal amount of cement. Last Friday afternoon most of the cement retailers around Qera were closed, and the few who were open had no cement products to sell.

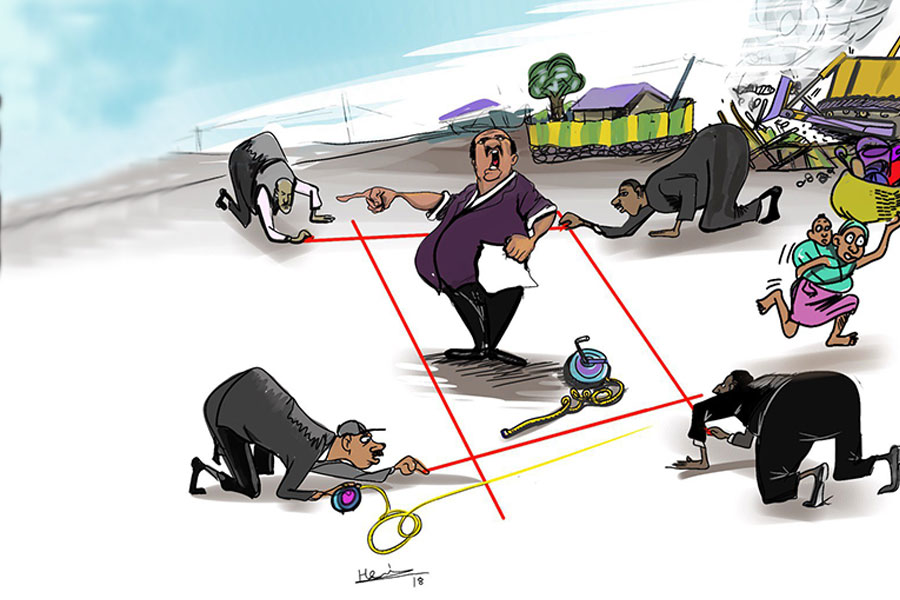

Recently, the Ministry of Trade & Industry decided that only five state-owned enterprises and party-affiliated companies can engage with the wholesale of cement products received from factories.

Guna Trading House Plc, Ambasel Trading House Plc, Biftu Adugna Business S.C., Ethiopian Industrial Input Development Enterprise, and the Ethiopian Trade Works Corporation are the companies that are authorised to exclusively wholesale Portland Pozzolana Cement (PPC) products.

The Ministry authorised the state-owned enterprises to stabilise the cement price and market, according to Eshete Asfaw, state minister for Trade & Industry.

"The cement market was disrupted due to cement supply shortages caused by the involvement of brokers and illegal trading activities," Eshete told Fortune.

However, the latest shortage was caused by transportation disruptions, according to Eshete.

The Ministry suspended the 12 cement wholesalers for two weeks before it came to the decision to authorise the five firms to wholesale cement products.

“During this period wholesalers across the country were halted from selling cement products while we were assessing the problems," said Eshete.

Cement transportation interruptions have induced a severe supply setback further complicating the problem. Even after the five companies were authorised to distribute the cement, they could not get trucks to transport the products since most of the vehicles in the country were deployed to Djibouti to transport fertiliser.

The main challenge to the wholesalers is that there is no sufficient cement production, according to Tewodros Mekonen, Habesha Cement's distributor. "The recent decision by the Ministry of Trade & Industry didn't affect us as we can still distribute bulk and Ordinary Portland Cement," said Tewodros. "But the main problem is the cement production shortage from the factories. We can't get as much cement as we want, because the factories are not producing enough."

The other challenge that the wholesalers are facing is the price ceiling, according to Tewodros. "We've been ordering cement products from factories at higher prices than those recently set by the Ministry. We haven't yet even received what was ordered months ago."

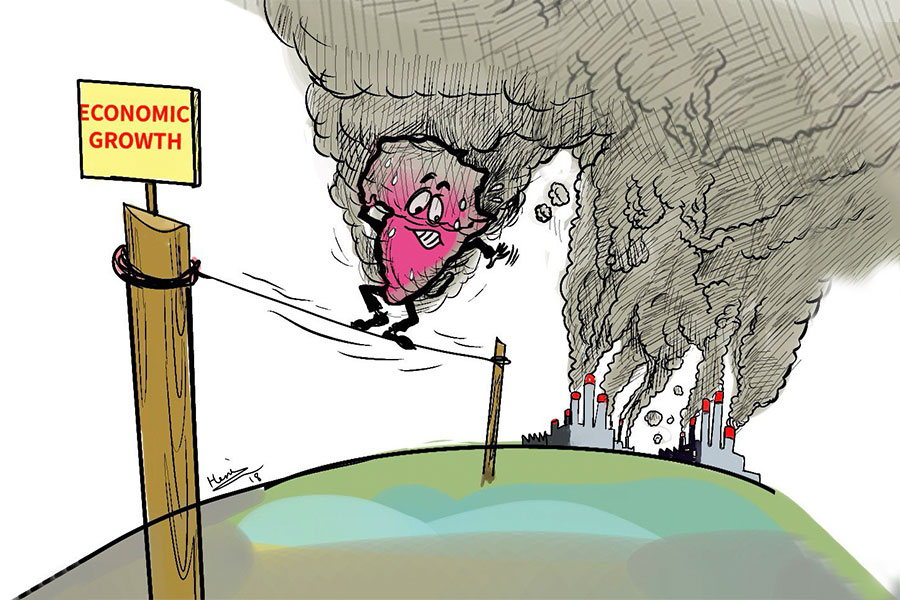

Recurrent disruptions are nothing new in this industry. Last year, from April to August, cement factories were facing electric power supply shortages, according to Haile Assegide, president of the Ethiopian Cement Producers Association and CEO of Derba Cement.

Most of the cement factories were producing half of their capacity due to electric power rationing, according to Haile.

The cement industry has been encountering technical and security problems as well. Because of these problems, the production of cement is declining of late.

Derba Cement has been shut down for 75 days between March 17 and June 1, 2020. The factory stopped operations because of the armed attack inflicted on its senior executives, all of them foreigners, in which one died and four were injured, according to Haile.

The factory, which produces 60,000ql of cement a day, is also facing transportation problems.

“When we started production on June 1," said Haile, "there was no sufficient transportation facility to supply our products to the market."

Dangote Cement and Mugher Cement also stopped operations recently to undergo maintenance.

Habesha Cement S.C., which was producing 15,000ql of cement a day, has also stopped production and sales since May 11, 2020, because of technical problems, according to Dilnesa Ejigu, production manager at the company.

During the electric power rationing last year, the factory was producing 10,000ql a day, half of its production capacity.

“We've been suffering from power shortages, especially in May and June of last year,” he said.

In December and January, the price of a quintal of cement was between 340 Br to 350 Br. However, the price was hiked to 480 Br to 500 Br in late May and early June. Following this price hike, the Ministry of Trade & Industry intervened and set a price cap for cement factories and retailers to restore the price to what it was in December and January.

The Ministry set 214 Br to 230 Br for a quintal as a factory gate price and 342 Br as a maximum retail price, according to Eshete.

“To stabilise the price of cement," said Eshete, "we've decided the retailers' profit margins should not exceed 20 Br a quintal,” he told Fortune.

The main problem is the disequilibrium between supply and demand; thus, authorities should be working on production solutions, argued Tekie Alemu, an assistant professor of economics at Addis Abeba University.

The government should work on boosting the supply of cement by helping the factories to produce to their full capacity instead of regulating the market, according to Tekie.

“This regulation and bureaucracy might hinder smooth production, bring unemployment, and disrupt trading networks,” he said. "The general inflation also has an immediate impact on the price of cement."

"The government should formalise and standardise the brokerage sector instead of driving the brokers out of the market as they are the means of information and the trading networks," Tekie said. "In order for the factories to function safely, imposing order and preserving peace is also a must."

Currently, the cement factories across the country are producing 17.1 million quintals of cement a year.

PUBLISHED ON

Jun 14,2020 [ VOL

21 , NO

1051]

Fortune News | May 24,2025

Viewpoints | Mar 13,2021

Radar | Nov 05,2022

Radar | Jan 26,2019

Fortune News | Aug 27,2022

Fortune News | Jun 05,2021

Fortune News | Feb 07,2024

Featured | Oct 12,2019

Agenda | Nov 27,2018

Featured | Sep 04,2021

Dec 22 , 2024 . By TIZITA SHEWAFERAW

Charged with transforming colossal state-owned enterprises into modern and competitiv...

Aug 18 , 2024 . By AKSAH ITALO

Although predictable Yonas Zerihun's job in the ride-hailing service is not immune to...

Jul 28 , 2024 . By TIZITA SHEWAFERAW

Unhabitual, perhaps too many, Samuel Gebreyohannes, 38, used to occasionally enjoy a couple of beers at breakfast. However, he recently swit...

Jul 13 , 2024 . By AKSAH ITALO

Investors who rely on tractors, trucks, and field vehicles for commuting, transporting commodities, and f...

Oct 4 , 2025

Eyob Tekalegn (PhD) had been in the Governor's chair for only weeks when, on Septembe...

Sep 27 , 2025

Four years into an experiment with “shock therapy” in education, the national moo...

Sep 20 , 2025

Getachew Reda's return to the national stage was always going to stir attention. Once...

Sep 13 , 2025

At its launch in Nairobi two years ago, the Africa Climate Summit was billed as the f...